Device for delivery motion switch to bicycle driving device

A technology of transmission and movement, which is applied in the direction of wheel transmission, bicycle accessories, bicycle gear transmission mechanism, etc., and can solve the problems of hindering the arrangement of fast tensioning devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

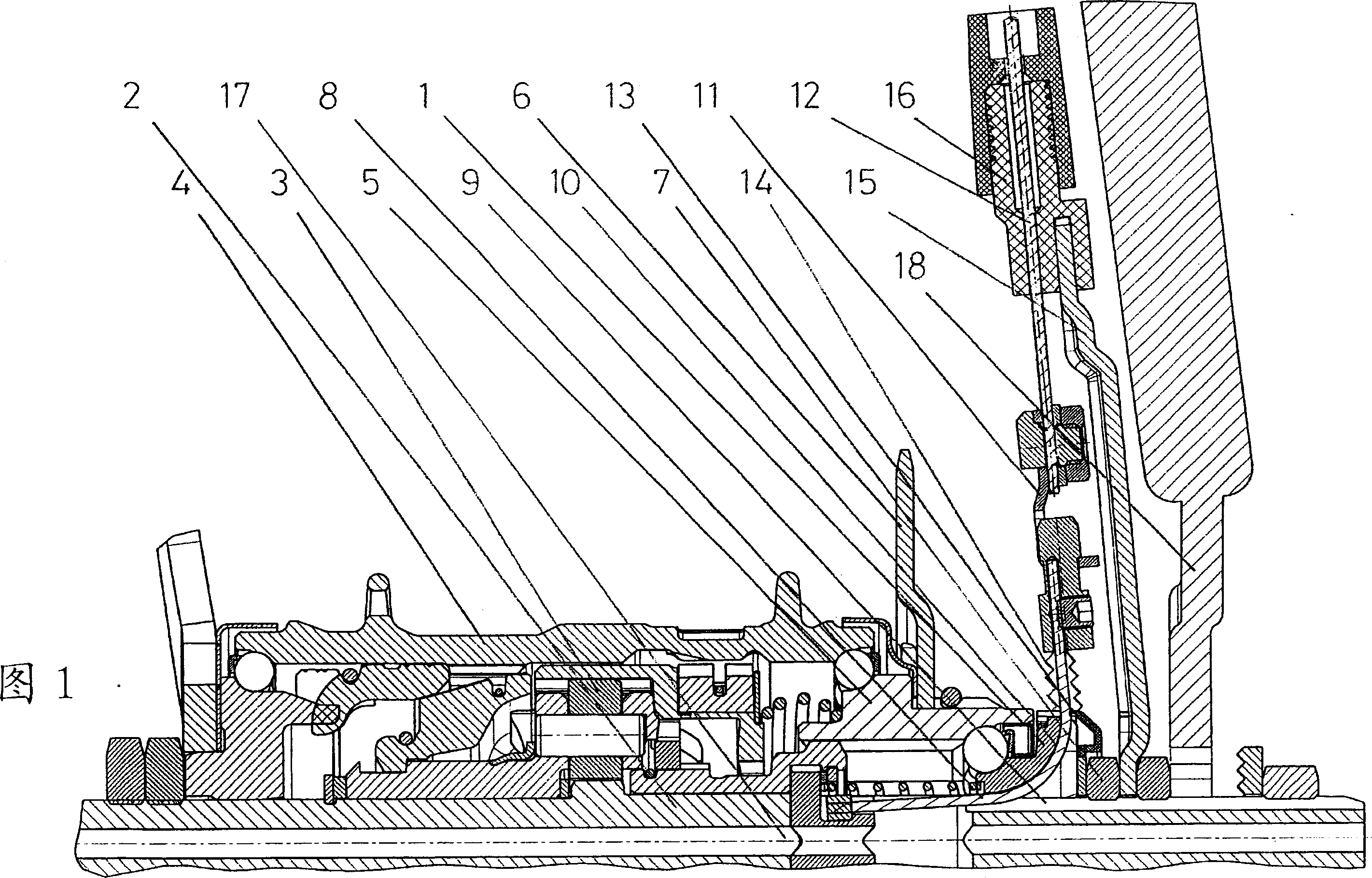

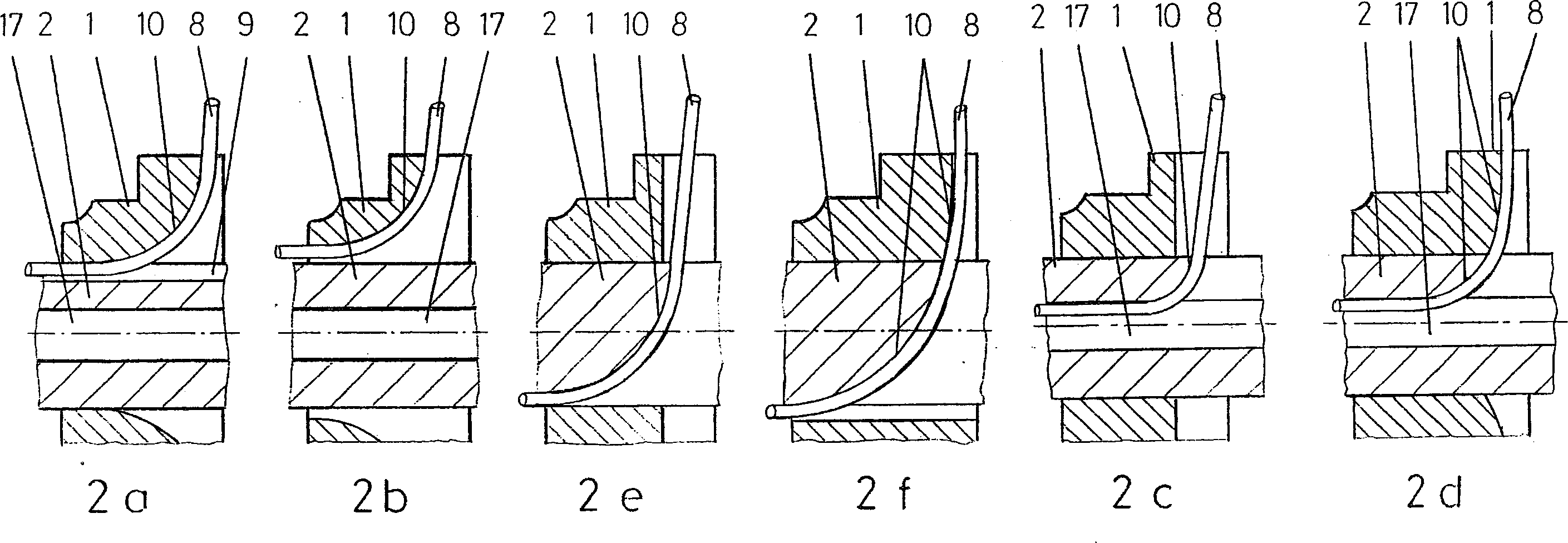

[0019] FIG. 1 shows a multi-speed transmission sleeve with a device for transmitting a switching movement between a bearing cone 1 and a shaft 2 . The multi-speed transmission sleeve consists of a sleeve 4 surrounding the transmission 3 which rotates about a shaft 2 fixed at the outer end of the frame. A ball bearing is arranged on both sides of the sleeve 4 , wherein one side of the inner ball raceway is arranged on a rotation-proof structure of the shaft 2 . The sleeve 4 rests flanking on a drive 5 , which likewise rests rotatably on the bearing cone 1 . The wing 6 is secured against rotation on the drive 5 and is axially secured with a tensioning ring. The bearing cone 1 is arranged on the shaft 2 in a rotationally fixed manner, so that the shaft 2 is shaped, or its circumference is flattened at two opposite points, and the inner contour of the bearing cone 1 is adjusted accordingly. The transmission element moving linearly from the converter is in the form of a steel cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com