Connecting structure of multi-ring drum drying machine

A technology of drum dryer and connection structure, which is applied in non-progressive dryers, dryers, drying solid materials, etc., and can solve problems such as body damage, deformation, welding cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

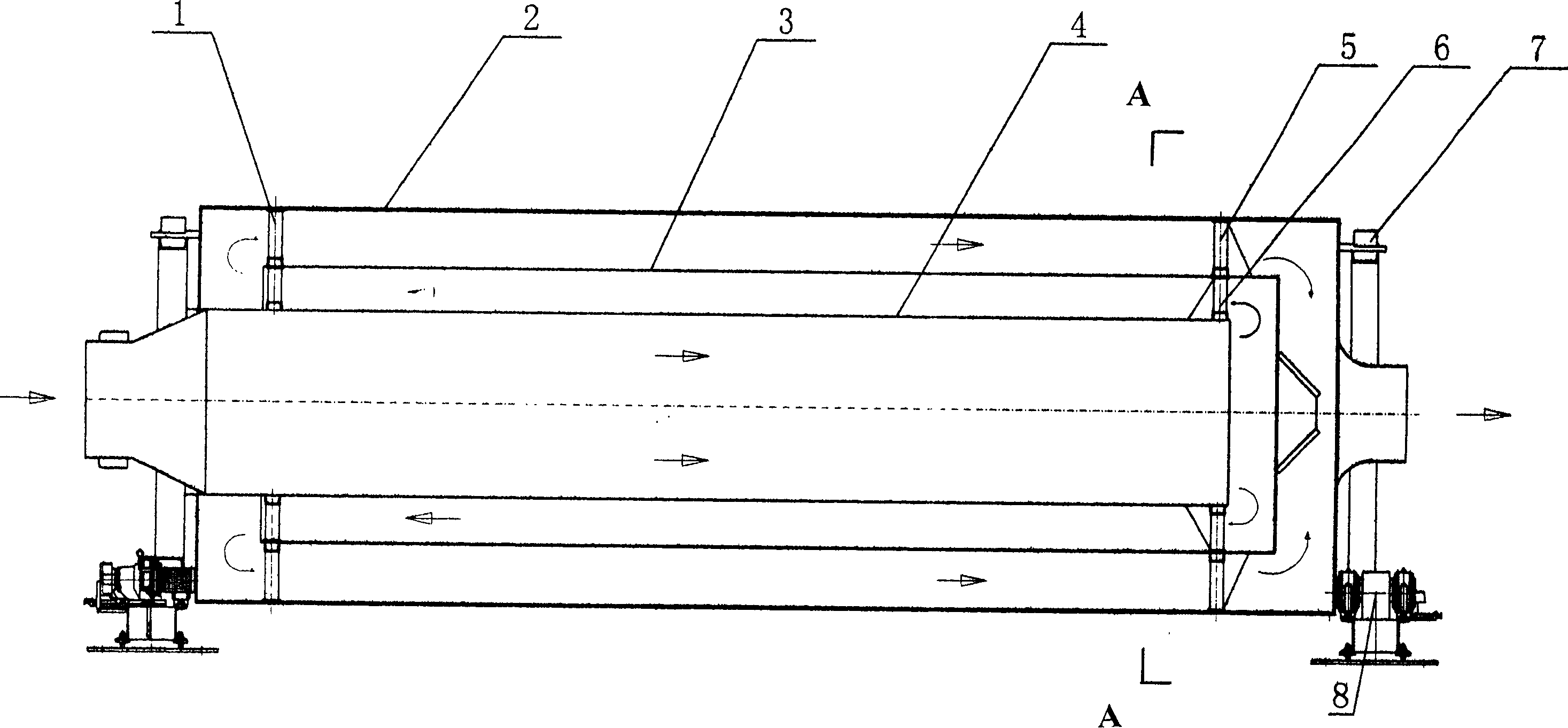

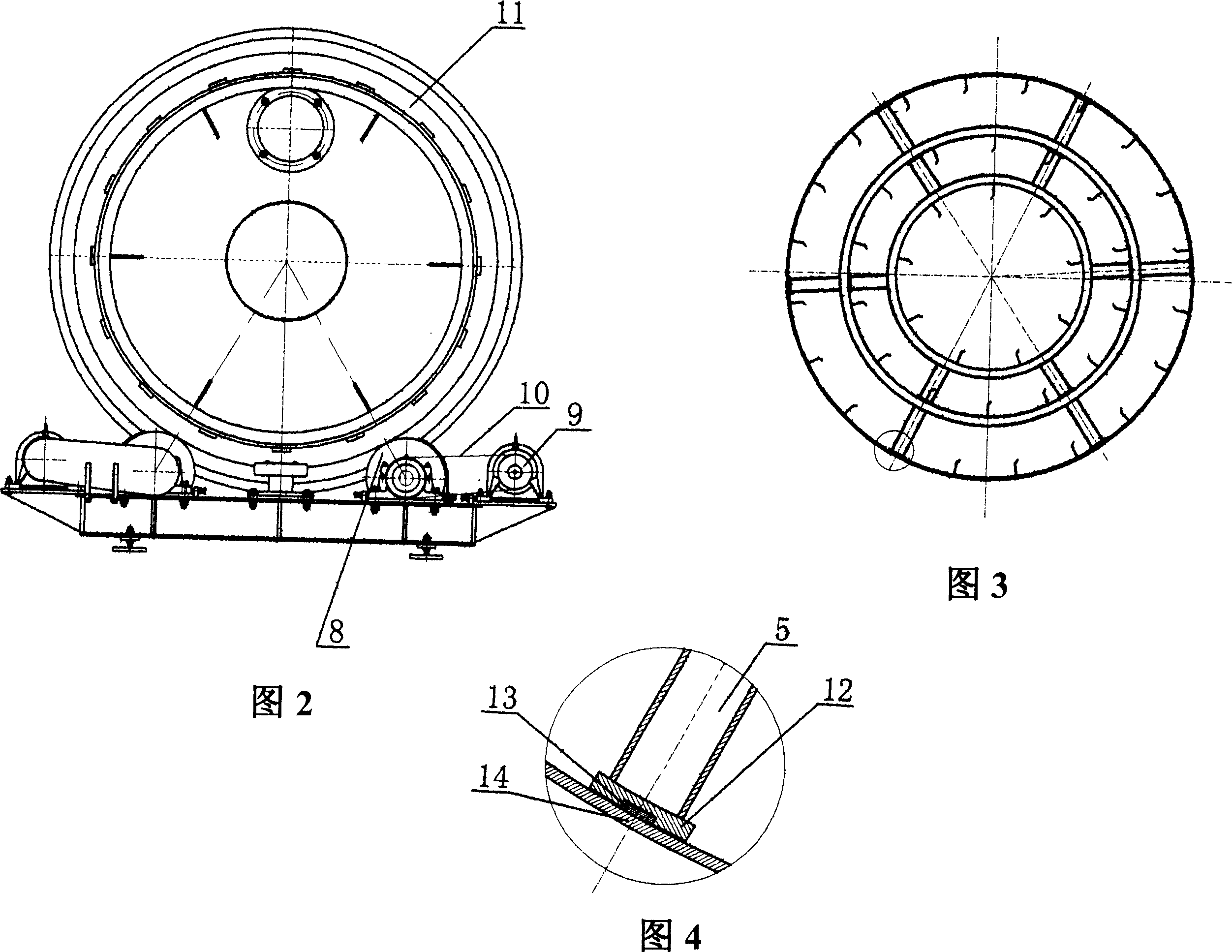

[0012] Such as figure 1 As shown in -4, the structure of the present invention is as follows: a multi-ring drum dryer 11 is composed of inner, middle and outer ring drums 4, 3, 2, and there are six supporting rods at both axial ends of each ring drum along the radial direction. Support, wherein one end is a fixed end support rod 1, and the other end is a movable end support rod 5,6. The two ends of the fixed end support rod 1 between the inner ring drum 4 and the middle ring drum 3 are respectively welded to the inner ring drum 4 and the middle ring drum 3, and the two ends of the fixed end support rod 1 between the middle ring drum 3 and the outer ring drum 2 are respectively Welded with middle ring drum 3 and outer ring drum 2. One end of the movable end support rod 6 between the inner ring drum 4 and the middle ring drum 3 is welded on the inner ring drum 4 , and the other end is provided with a chute 12 , which is slidingly matched with the slide block 13 welded on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com