Housing cage for holding built-in modules

A cage, built-in technology, applied in the direction of rack/frame structure, chassis/cabinet/drawer parts, instruments, etc., can solve problems such as unreasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

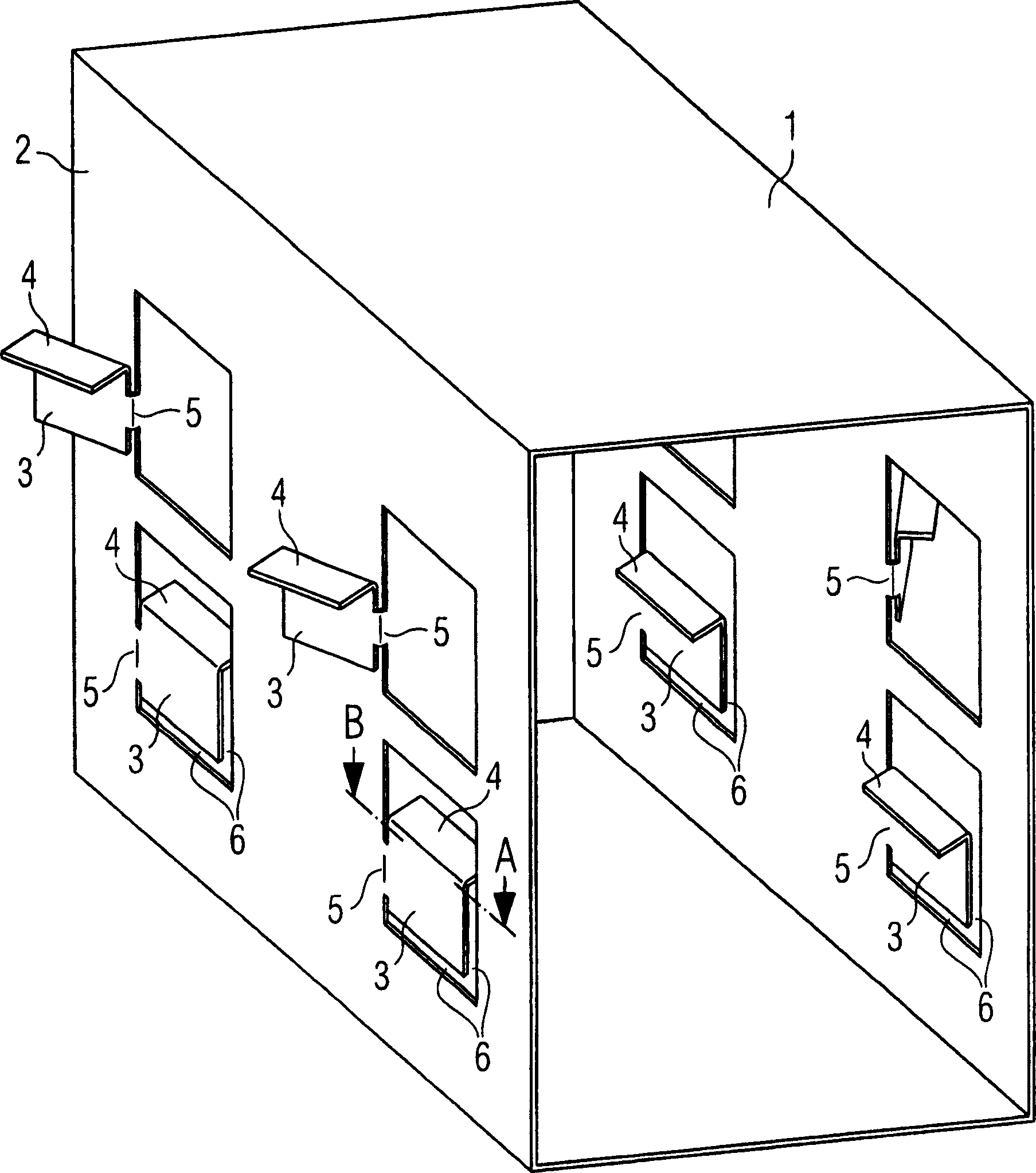

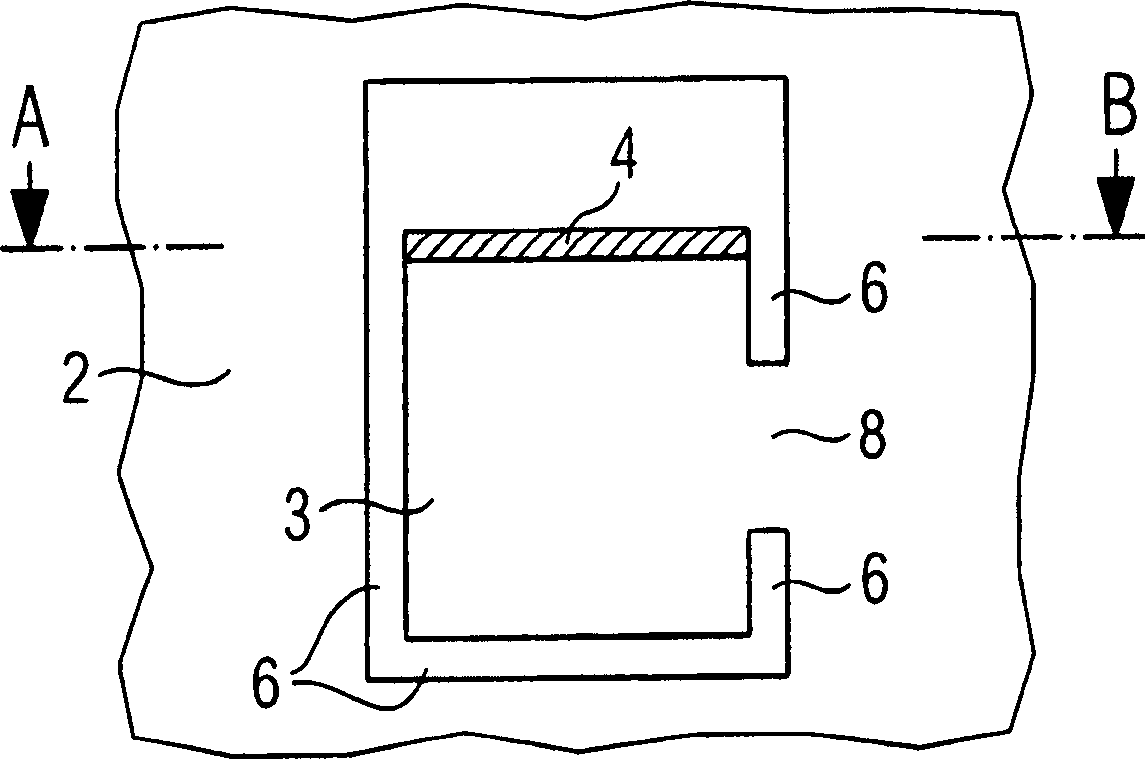

[0016] figure 1 A housing-type cage 1 is shown, the walls 2 of which each have four bendable wall sections 3 . The bendable wall section 3 is connected at an angle to the support surface 4 . In addition, the flexible wall section 3 is connected to one of the walls 2 of the housing-type cage 1 at a first leg 5 . Cut-outs 6 are provided between the other sides of the wall section 3 and the wall 2 of the housing-type cage.

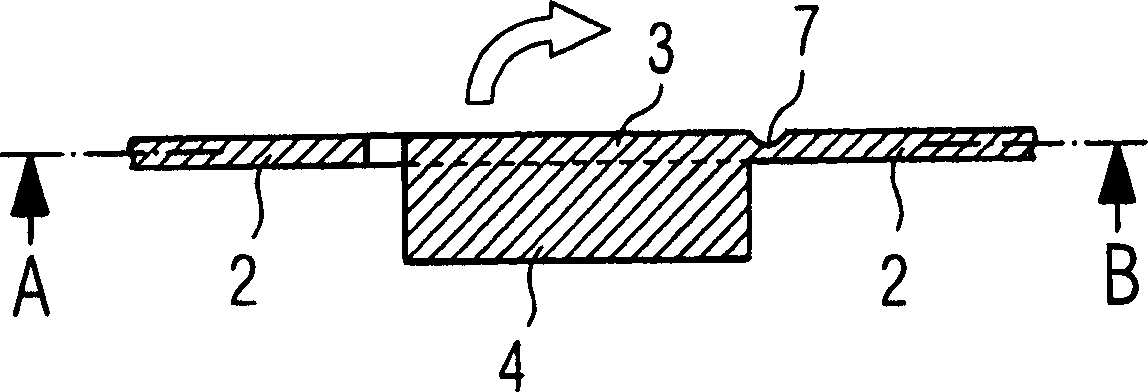

[0017] figure 2 A detailed plan view of the first embodiment of the wall section 3 along section A-B is shown. Here, the wall section 3 is offset from the wall 2 of the shell-type cage 1 with the contact surface 4 connected thereto via a groove 7 . If a built-in module is to be received in this shell-type cage 1, this built-in module requires that the support surface 4 is removed from the inside of the shell-type cage 1, so that the wall section 3 and the supporting frame connected thereto face 4 in figure 2 The direction of the arrow is bent from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com