Apparatus and method for printing plate separating which with one stow

A printing plate and stacking technology, applied in the direction of pile separation, object separation, transportation and packaging, etc., can solve the problems of double sheets, complicated separation, and hindering the separation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

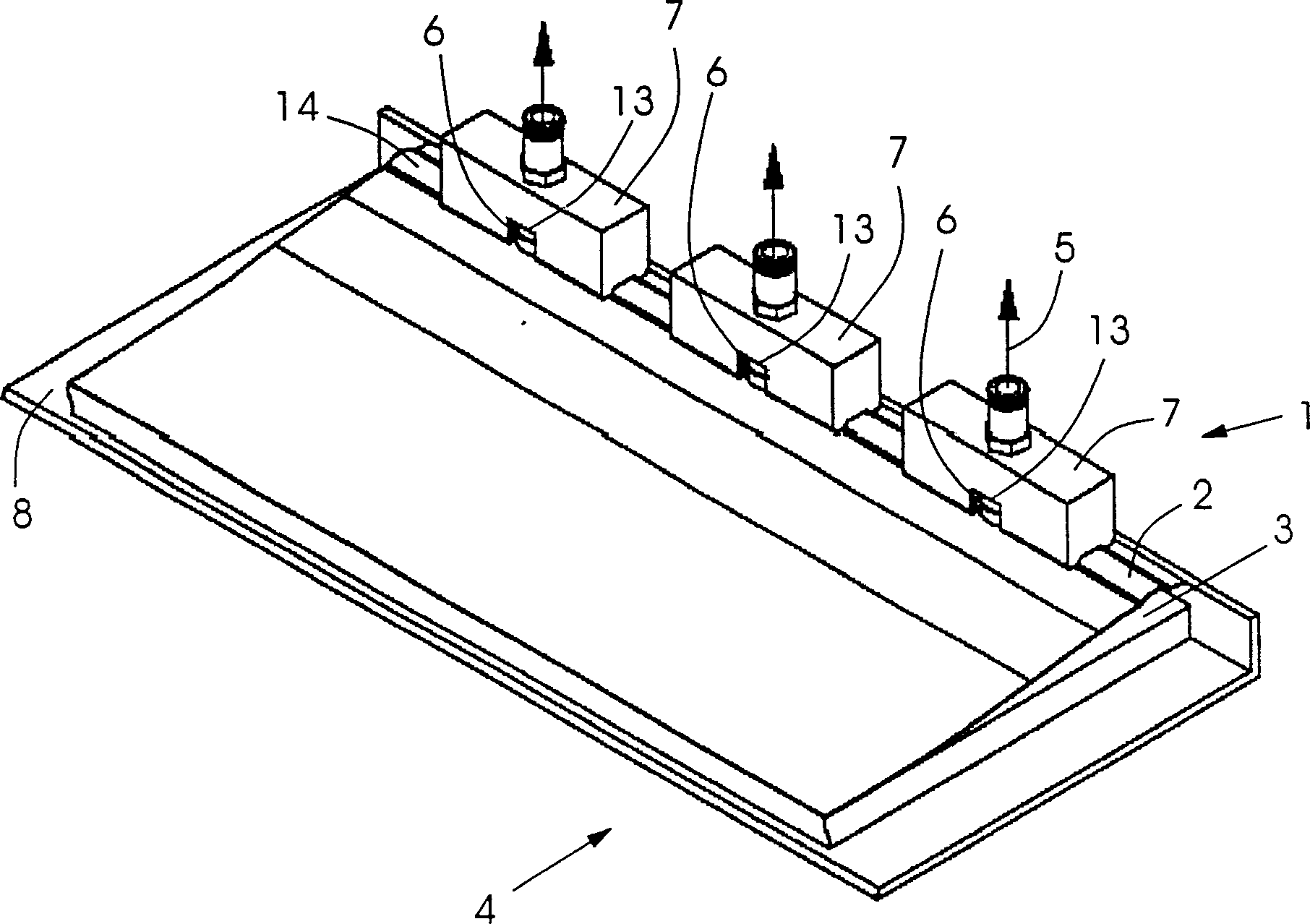

[0029] figure 1 Suction elements 6 of a lifting device 1 , not all of which are shown, are shown schematically with shaping elements 7 . The suction air flow is conducted through the suction element 6 in the direction of the arrow 5 via a duct not shown. As a result, the porous intermediate mat 2 or printing plates 3 placed on a printing plate stack 4 in the partially shown cassette 8 can be sucked in and then lifted by the lifting device 1 . It can also be used for the intermediate cushion layer 2 which is not porous. The same reference numerals denote the same elements below.

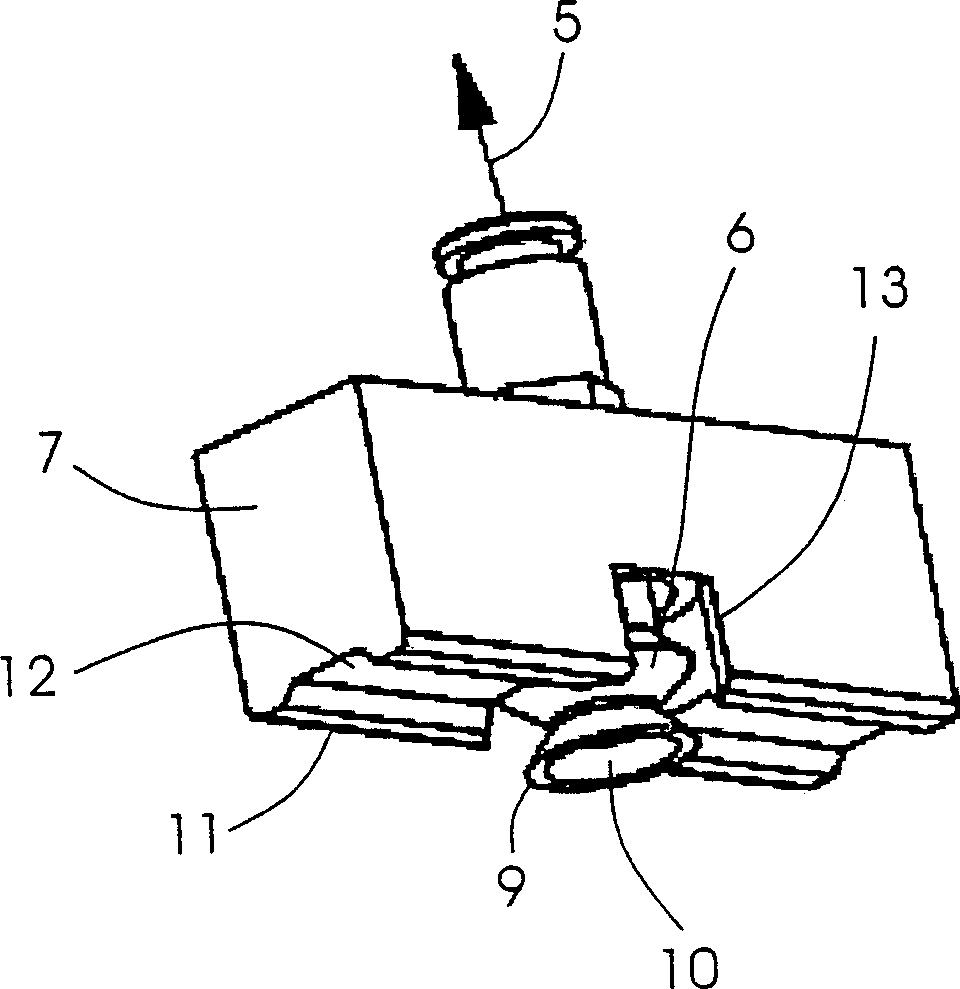

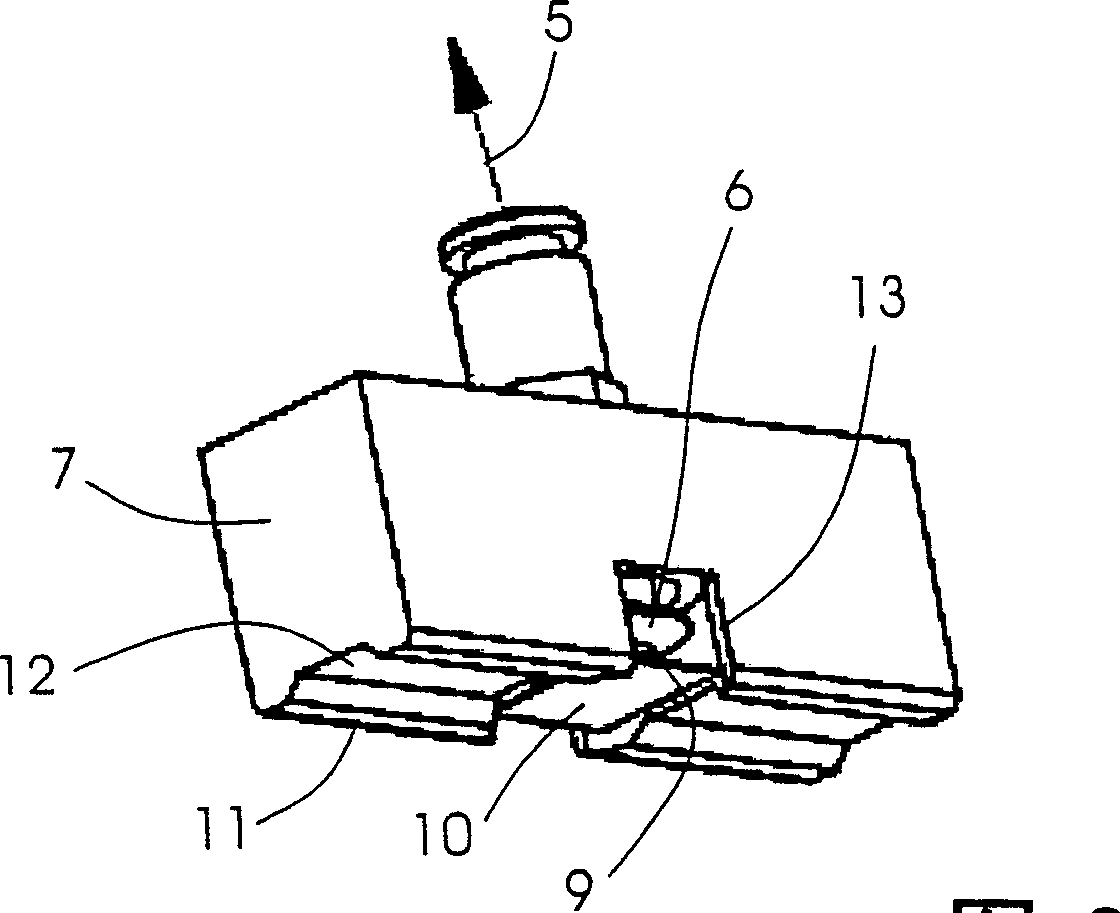

[0030] Such as figure 2As shown, the shaping element 7 here consists of a solid molded part which surrounds a suction element 6 . The shaping element 7 has a boundary 11 as a lower boundary surface, which is deformed by the first recess in such a way that a continuous groove 12 is formed on the bottom surface of the shaping element 7 . The groove 12 is interrupted only where the shaping element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com