Plastic thin-wall tube

A technology of plastic thin-walled and thin-walled tubes, which is applied in the direction of formwork/formwork/working frame, building components, and on-site preparation of building components, which can solve the inconvenience of construction, affect construction, and easy loosening and slipping of half parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

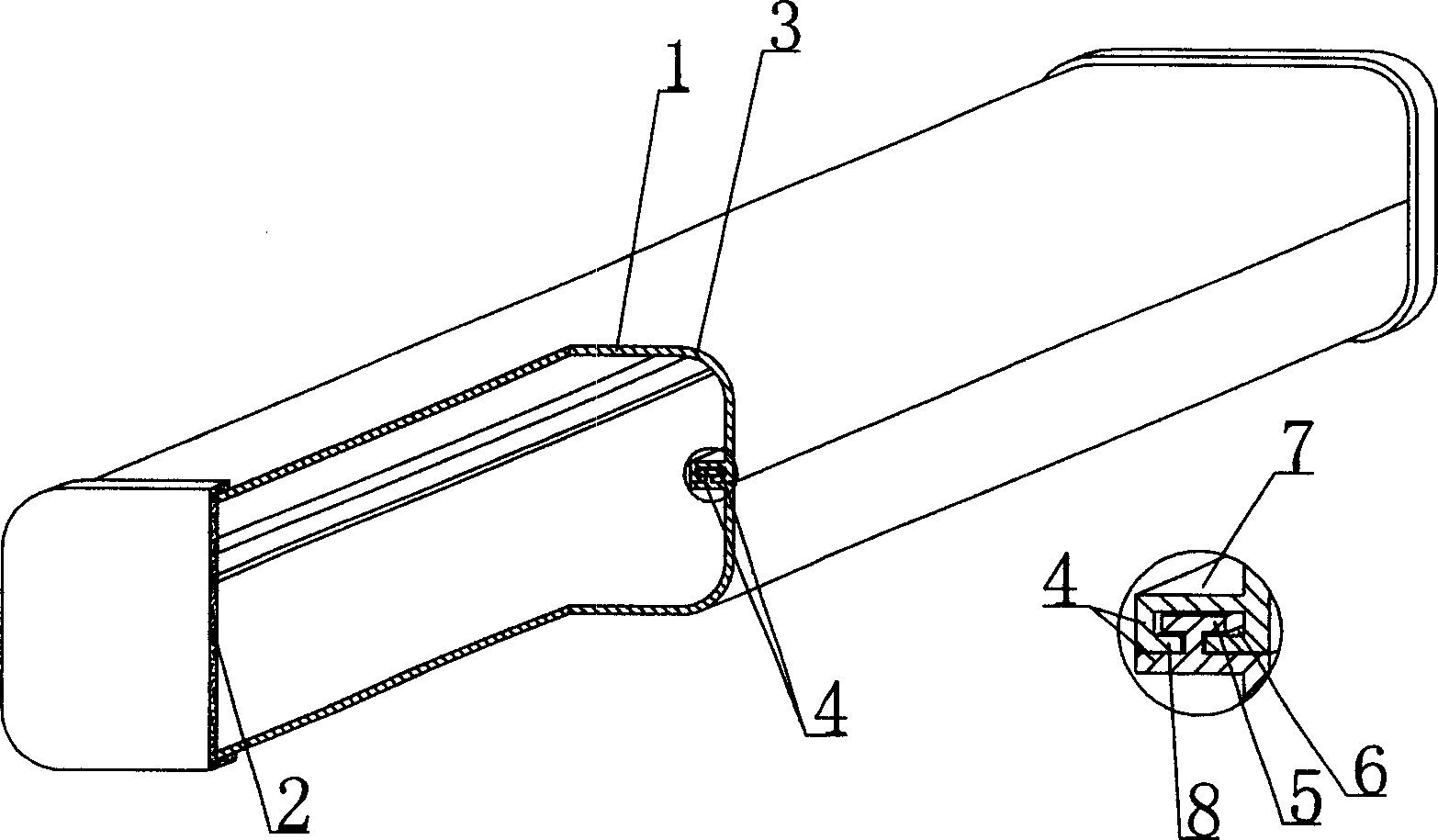

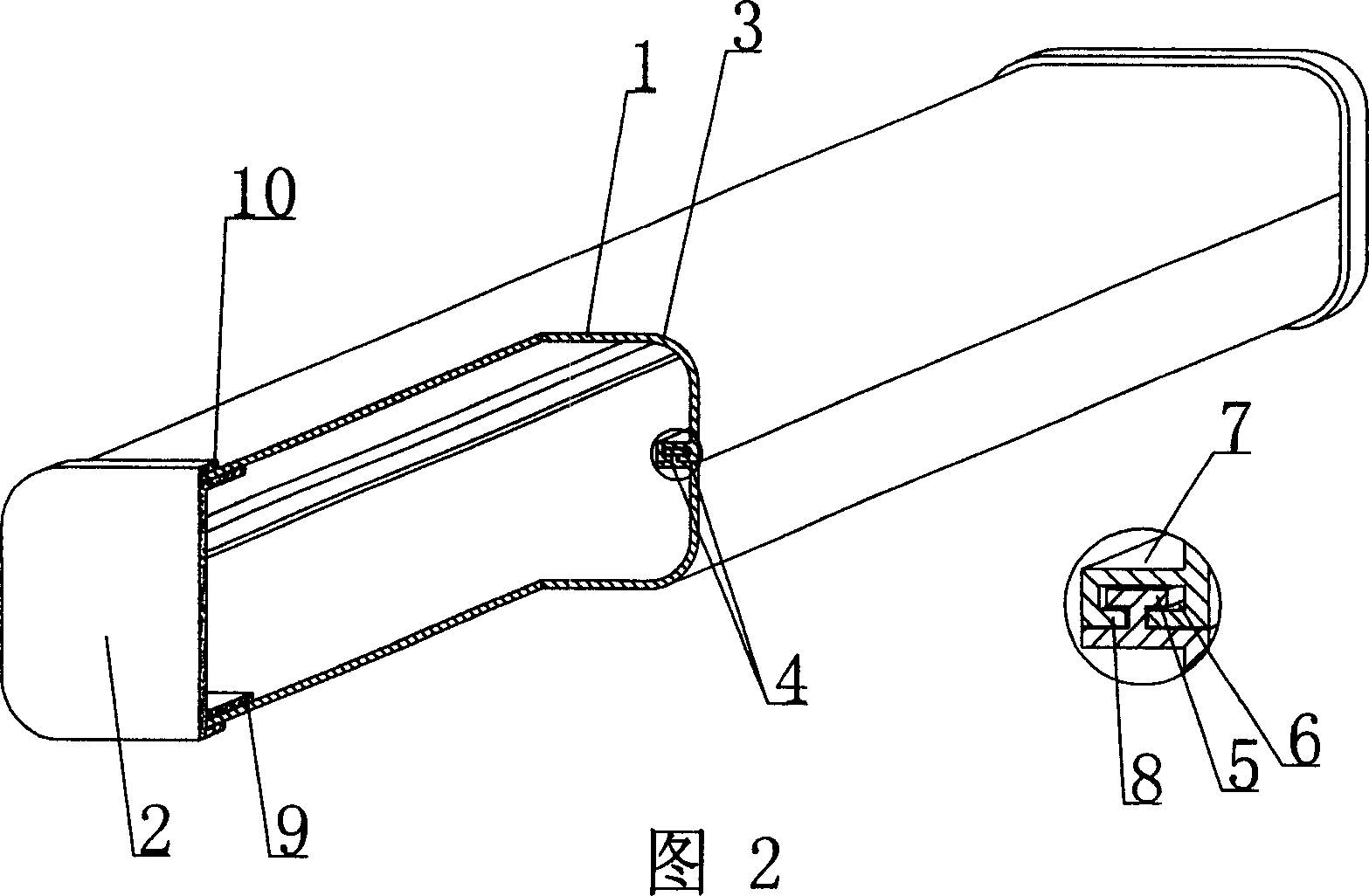

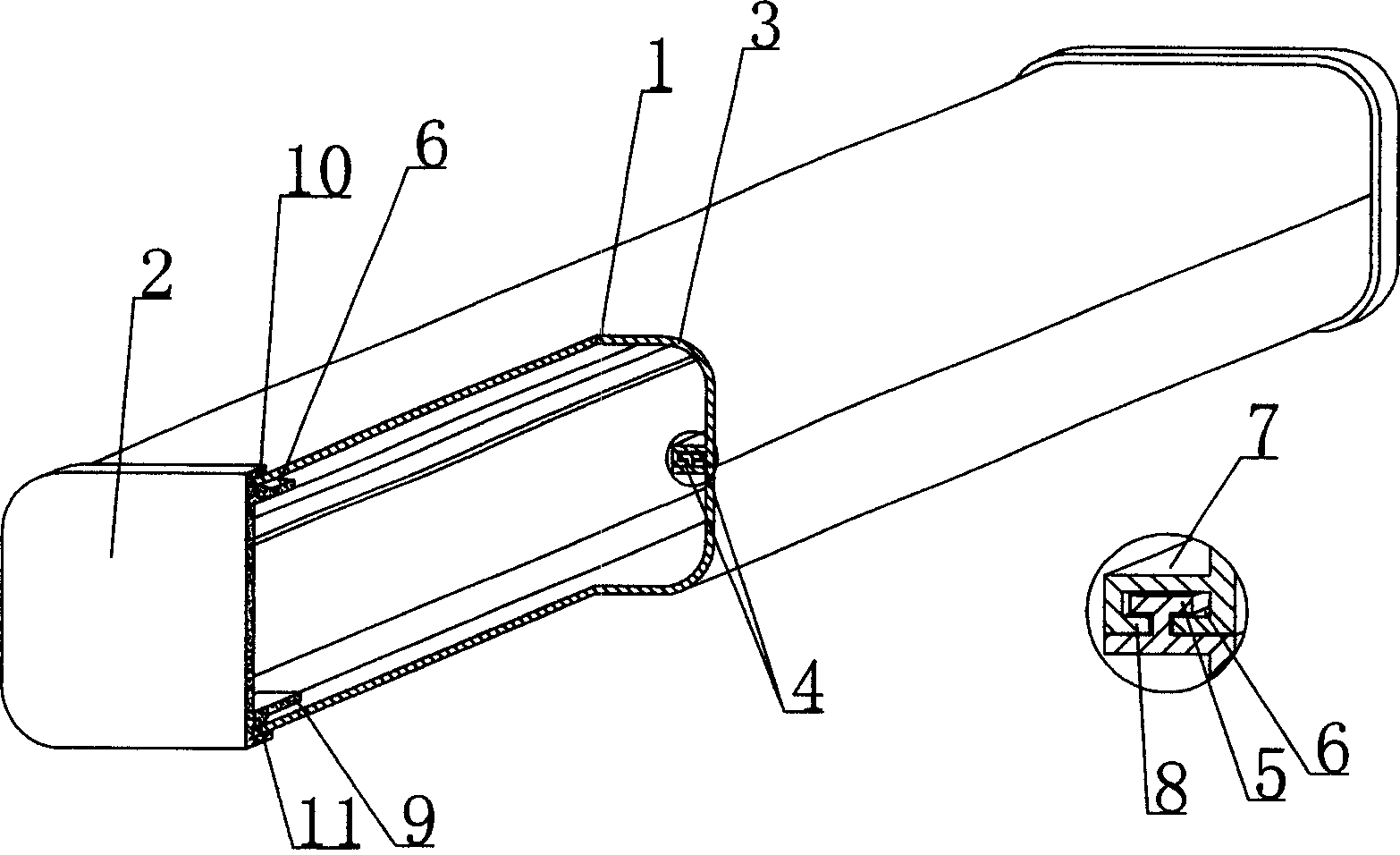

[0079]As shown in the accompanying drawings, the present invention comprises an annular thin-walled pipe body 1 and a sealing plate 2. The sealing plate 2 closes the pipe end of the annular thin-walled pipe body 1 to form a closed hollow thin-walled pipe. The annular thin-walled pipe body 1 consists of at least Two plates 3 are spliced together, and the splicing parts are connected to each other by connectors 4, the connectors 4 are male and female groove connectors, and the male strip 5 of the connector 4 is inserted into the female groove 6 for connection to form a splicing strip 7, which is characterized in that The connecting piece 4 is an anti-slip male and female groove connector, the female groove 6 is provided with an anti-slip component 8, and the splicing strip 7 has at least one male strip 5 or / and at least one female groove 6. In the attac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap