Plastic thin-wall tube

A technology of plastic thin-walled and thin-walled tubes, which is applied in the direction of formwork/formwork/work frame, building components, and on-site preparation of building components, which can solve the problems of poor integrity, low strength and rigidity, and easy looseness of half parts problems such as falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

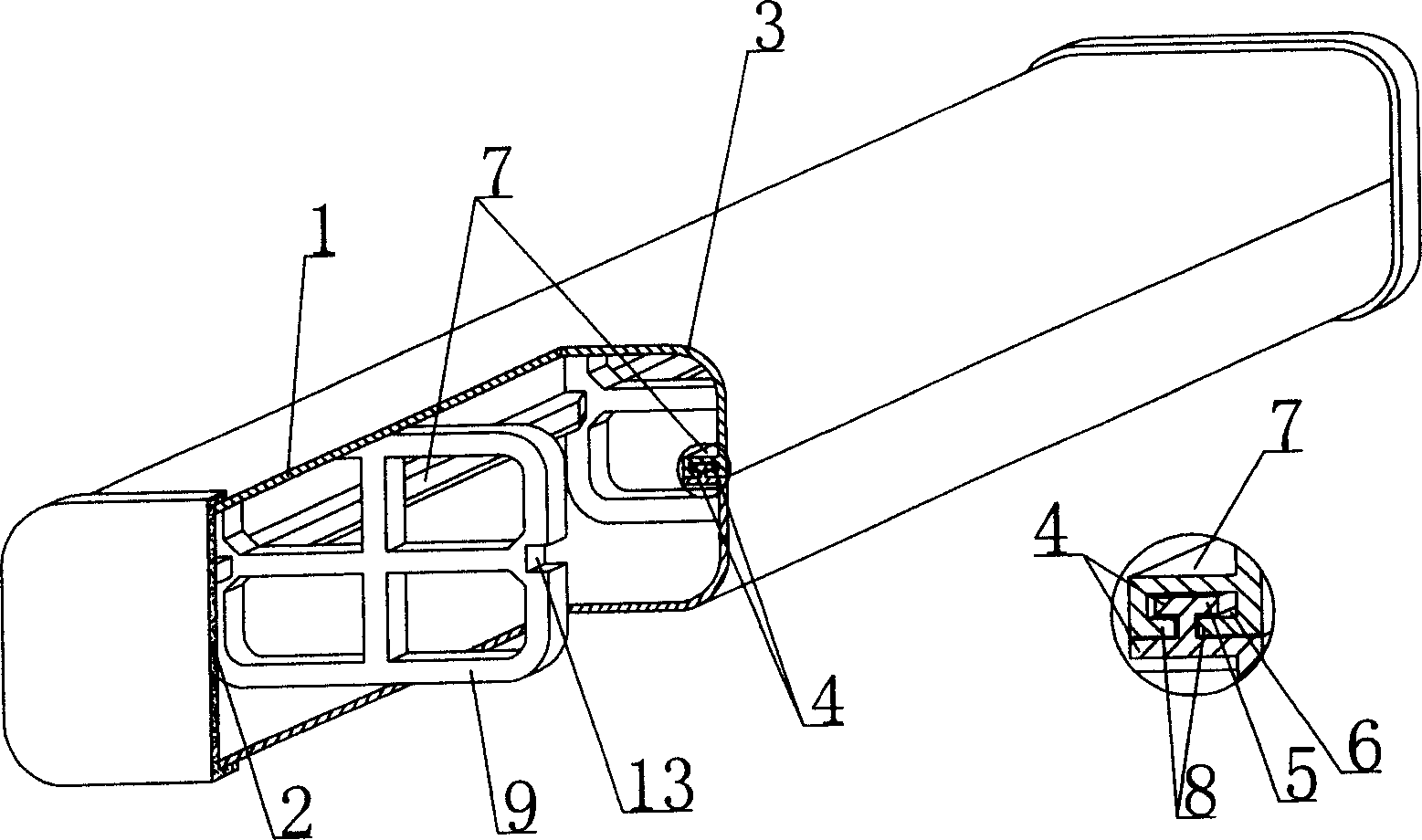

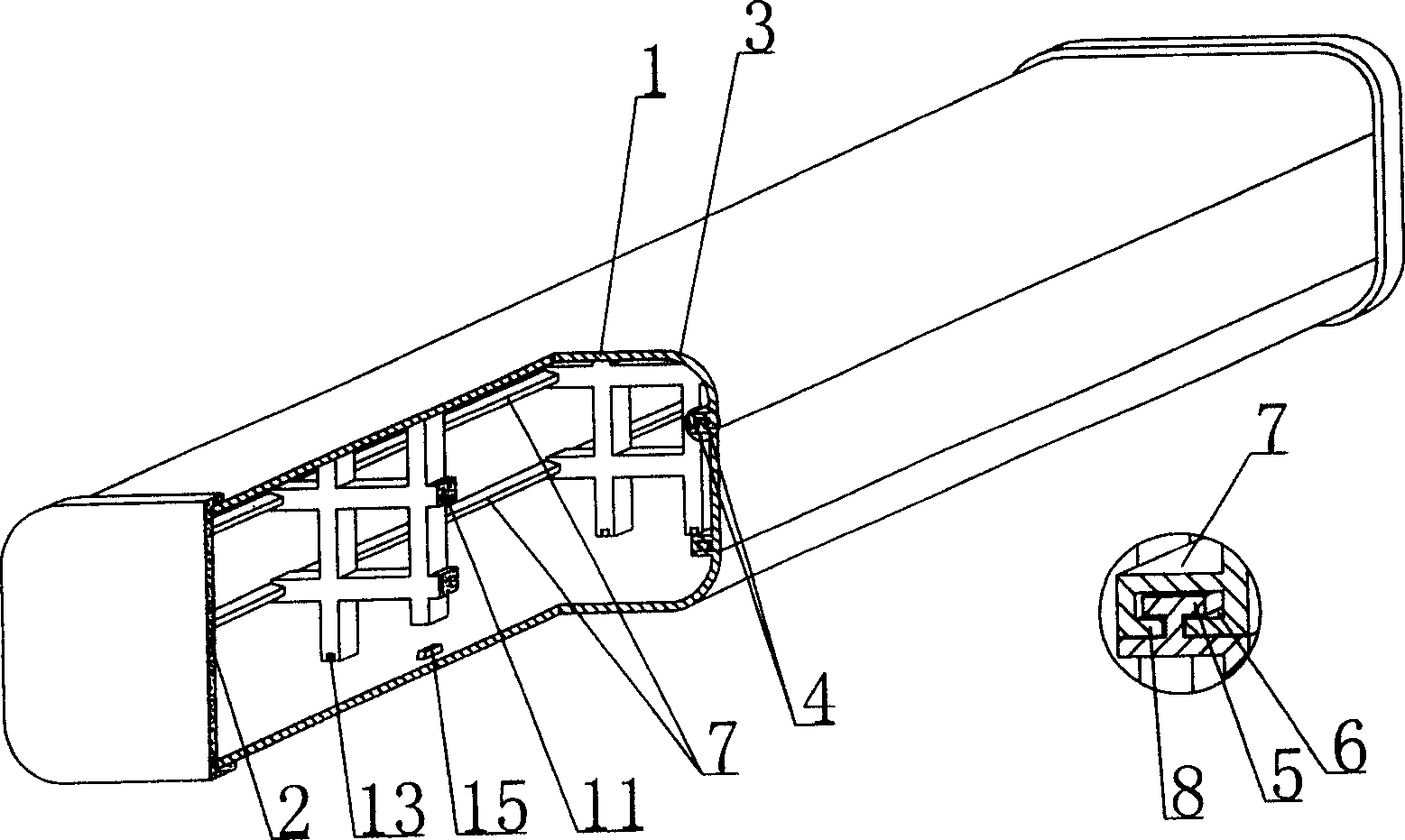

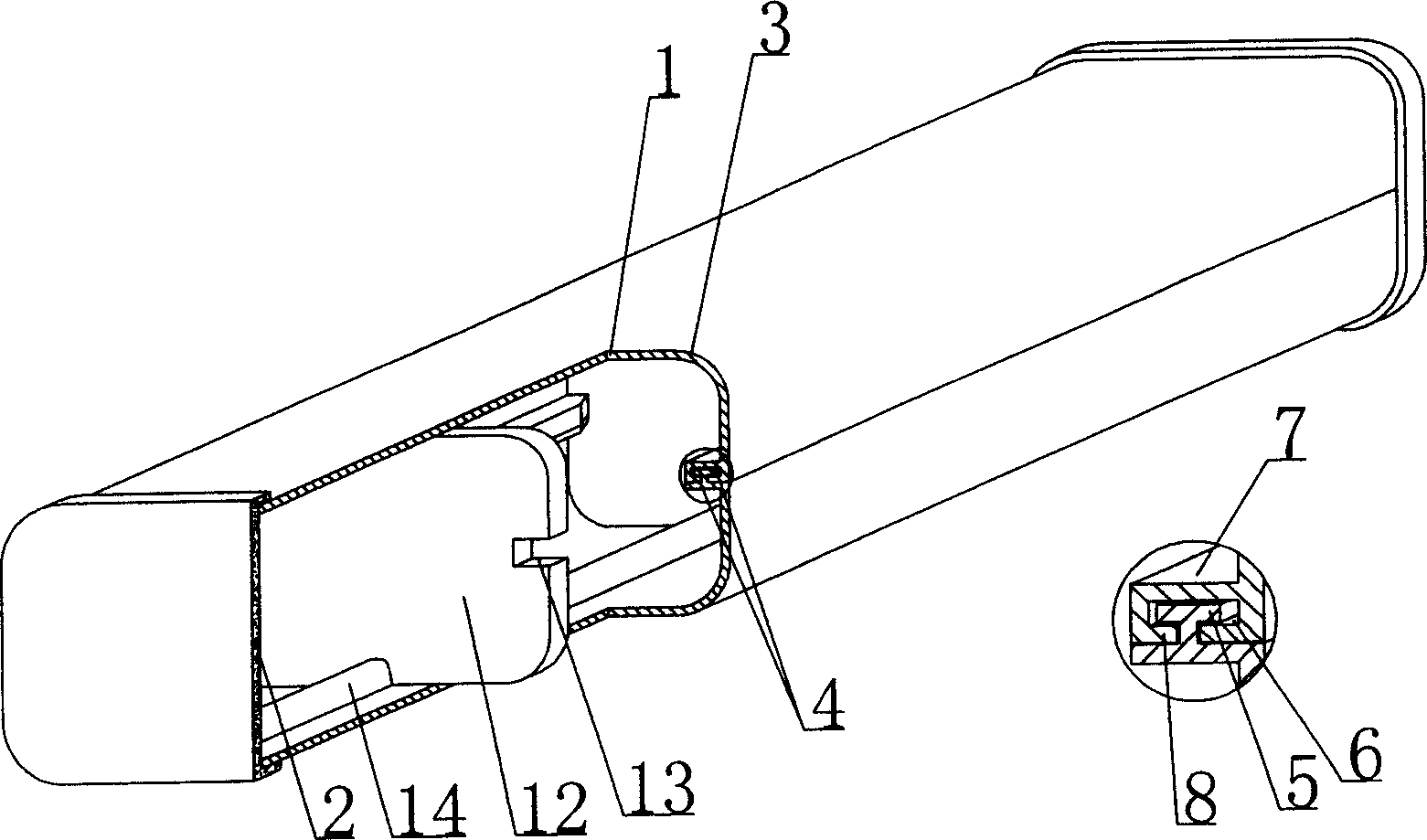

[0073] The present invention will be further described below in conjunction with the drawings and embodiments.

[0074] As shown in the drawings, the present invention includes an annular thin-walled tube body 1 and a sealing plate 2. The sealing plate 2 closes the tube end of the annular thin-walled tube body 1 to form a closed hollow thin-walled tube. The annular thin-walled tube body 1 is composed of at least The two plates 3 are spliced together, and the splicing part is connected to each other by the connecting piece 4, the connecting piece 4 is a male and female groove connecting piece, and the male strip 5 of the connecting piece 4 is inserted into the female groove 6 to connect to form a splicing strip 7, which is characterized by The said connector 4 is a non-slip male and female groove connector, the female groove 6 is provided with a non-slip member 8, and the inner cavity of the thin-walled tube 1 is provided with a detachable support rod ring 9, a support ring 10, A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap