Method for making five-string lute

A production method and pipa technology, applied in stringed instruments, instruments, musical instruments, etc., can solve the problem of lack of details in practical effects, and achieve the effects of soft timbre, wide range and rich chords

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

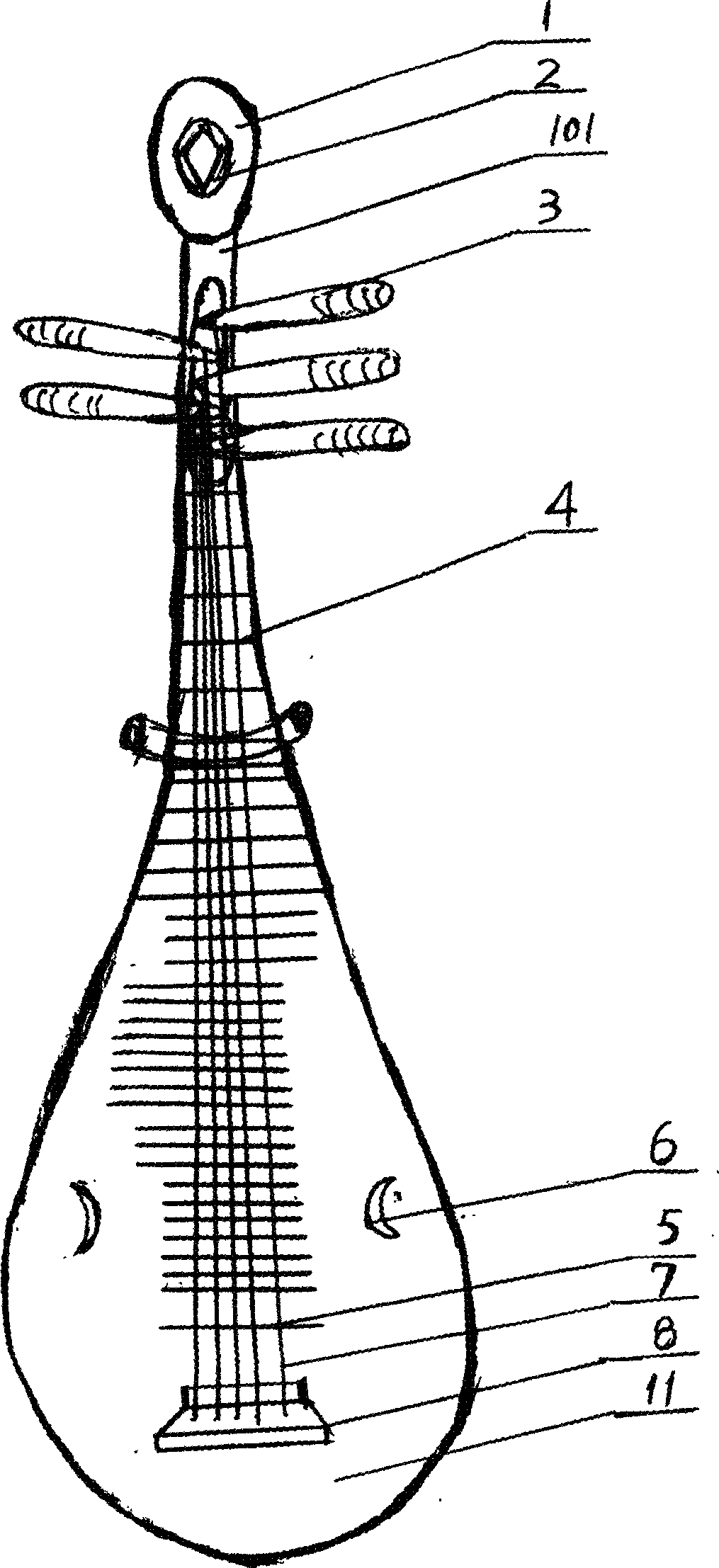

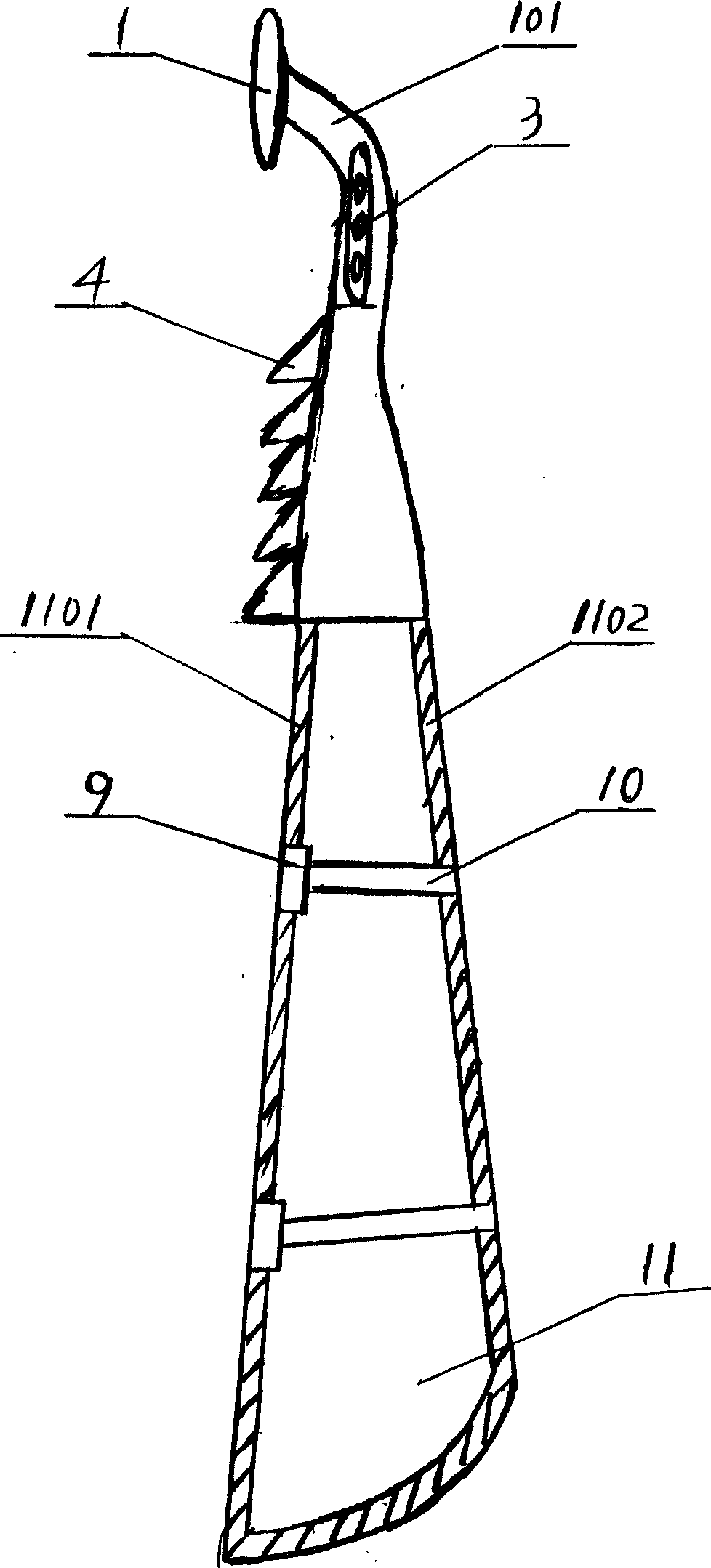

[0014] See attached figure 1 , attached figure 2 , the present invention and a kind of manufacture method of five-stringed pipa are to complete the making of five-stringed lute according to the following steps:

[0015] (1) Complete the various parts of the pipa in advance: piano head 1, head flower 2, main rod 101, piano frame 4, piano shaft 3, front panel 1101 of the piano body 11, rear panel 1102, frets 5, armrest 8 the production steps;

[0016] (2) Dig two crescent-shaped sound holes 6 on the abdomen of the front panel 1101 of the piano body 11 relative to the left and right positions of the strings 7;

[0017] (3) the fret 5 of twenty-five frets is installed on the piano body 1;

[0018] (4) Between the front panel 1101 and the rear panel 1102 of the piano body 1, at least two beams 9 and sound columns 10 connected to each other are arranged, wherein one end of the sound column 10 is connected to the rear panel. conflict, the other end of the sound column 10 conflic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com