A combination of digital printing and traditional tie-dyeing of cashmere fabric

A digital printing and cashmere technology, which is applied in the field of combining digital printing and traditional tie-dyeing technology, can solve the problems affecting fiber dyeing performance and hindering structure diffusion, and achieve the effect of good hand feeling, guaranteed quality and soft tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

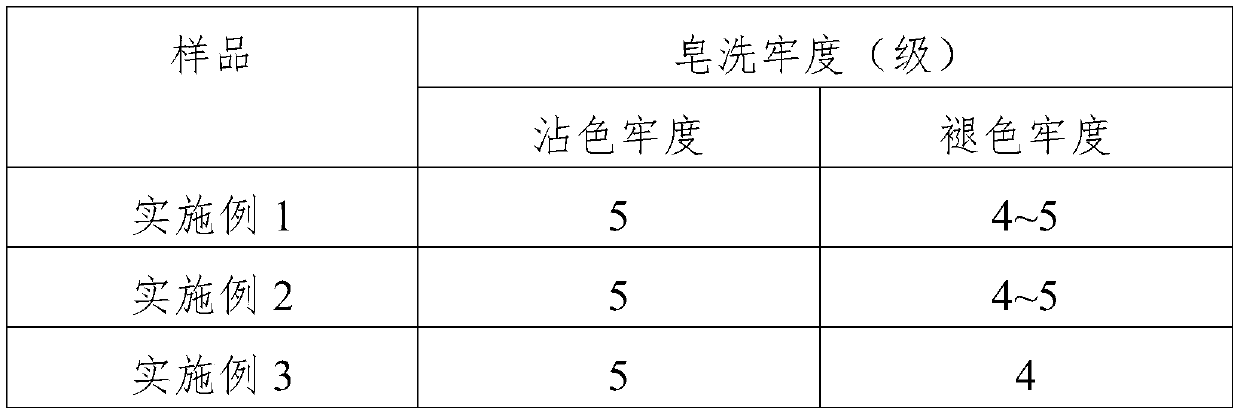

Examples

Embodiment 1

[0029] A combination process of digital printing of cashmere fabric and traditional tie-dyeing, comprising the following steps:

[0030] 1) Establish a plan: decompose the original traditional tie-dye graphics stored in the computer, then recombine to complete the pattern design, decompose the completed pattern design again, and determine the tie-dyeing method, tie-dyeing color and printing pattern;

[0031] 2) Tie-dyeing: Put the tied cashmere fabric into the dyeing pot for dyeing. The dyeing process is: at room temperature, the dye and water are proportioned to form a dye solution, and the dye solution is heated at a heating rate of 2°C / min. Warm up to 36°C, add tied cashmere fabric, soak for 35min, add soda ash and sodium sulfate, the amounts of soda ash and sodium sulfate are respectively 0.6% and 0.8% of the quality of cashmere fabric; then heat up to 75°C, keep warm for 40min; finally lower the temperature to room temperature at a cooling rate of 3°C / min, and the dyeing ...

Embodiment 2

[0036] A combination process of digital printing of cashmere fabric and traditional tie-dyeing, comprising the following steps:

[0037] 1) Establish a plan: decompose the original traditional tie-dye graphics stored in the computer, then recombine to complete the pattern design, decompose the completed pattern design again, and determine the tie-dyeing method, tie-dyeing color and printing pattern;

[0038] 2) Tie-dyeing: Put the tied cashmere fabric into the dyeing pot for dyeing. The dyeing process is: at room temperature, the dye and water are proportioned to form a dye solution, and the dye solution is heated at a heating rate of 2°C / min. Heat up to 40°C, add tied cashmere fabric, soak for 30min, add soda ash and sodium sulfate, the amount of soda ash and sodium sulfate is respectively 0.5% and 1% of the quality of cashmere fabric; then heat up to 77°C, keep warm for 40 minutes; finally lower the temperature to room temperature at a cooling rate of 4°C / min, and the dyeing...

Embodiment 3

[0043]A combination process of digital printing of cashmere fabric and traditional tie-dyeing, comprising the following steps:

[0044] 1) Establish a plan: decompose the original traditional tie-dye graphics stored in the computer, then recombine to complete the pattern design, decompose the completed pattern design again, and determine the tie-dyeing method, tie-dyeing color and printing pattern;

[0045] 2) Tie-dyeing: Put the tied cashmere fabric into the dyeing pot for dyeing. The dyeing process is: at room temperature, the dye and water are proportioned to form a dye solution, and the dye solution is heated at a heating rate of 2°C / min. Warm up to 38°C, add tied cashmere fabric, soak for 32min, add soda ash and sodium sulfate, the amounts of soda ash and sodium sulfate are respectively 0.4% and 1.2% of the quality of cashmere fabric; then heat up to 75°C, keep warm for 40 minutes; finally lower the temperature to room temperature at a cooling rate of 5°C / min, and the dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com