Positioning apparatus and method of controlling positioning apparatus

A technology for positioning equipment and controllers, which is applied in the field of chip mounters and controls the positioning equipment, can solve the problems of increased cost and complex structure of exposure equipment, and achieve the effect of cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

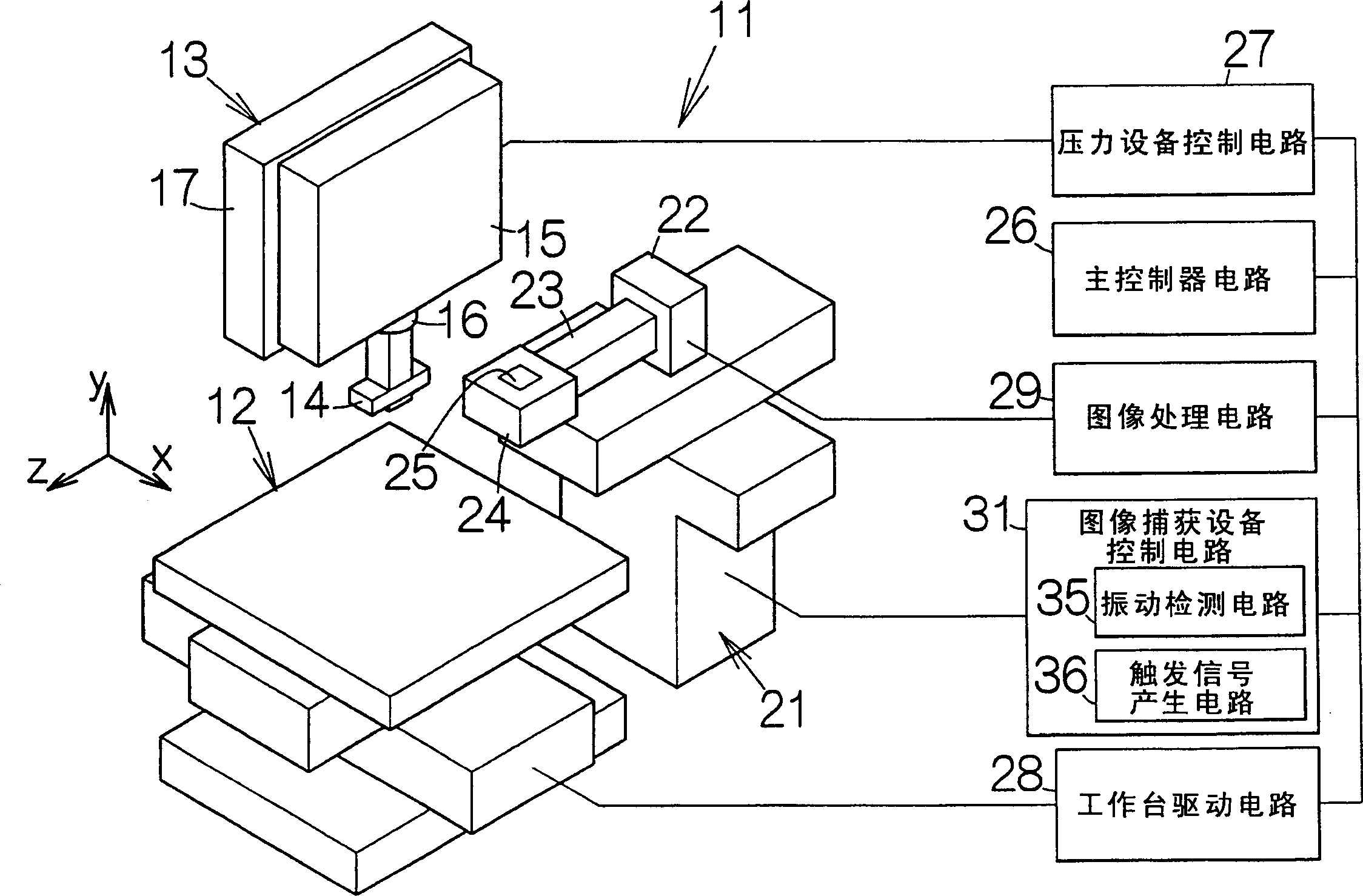

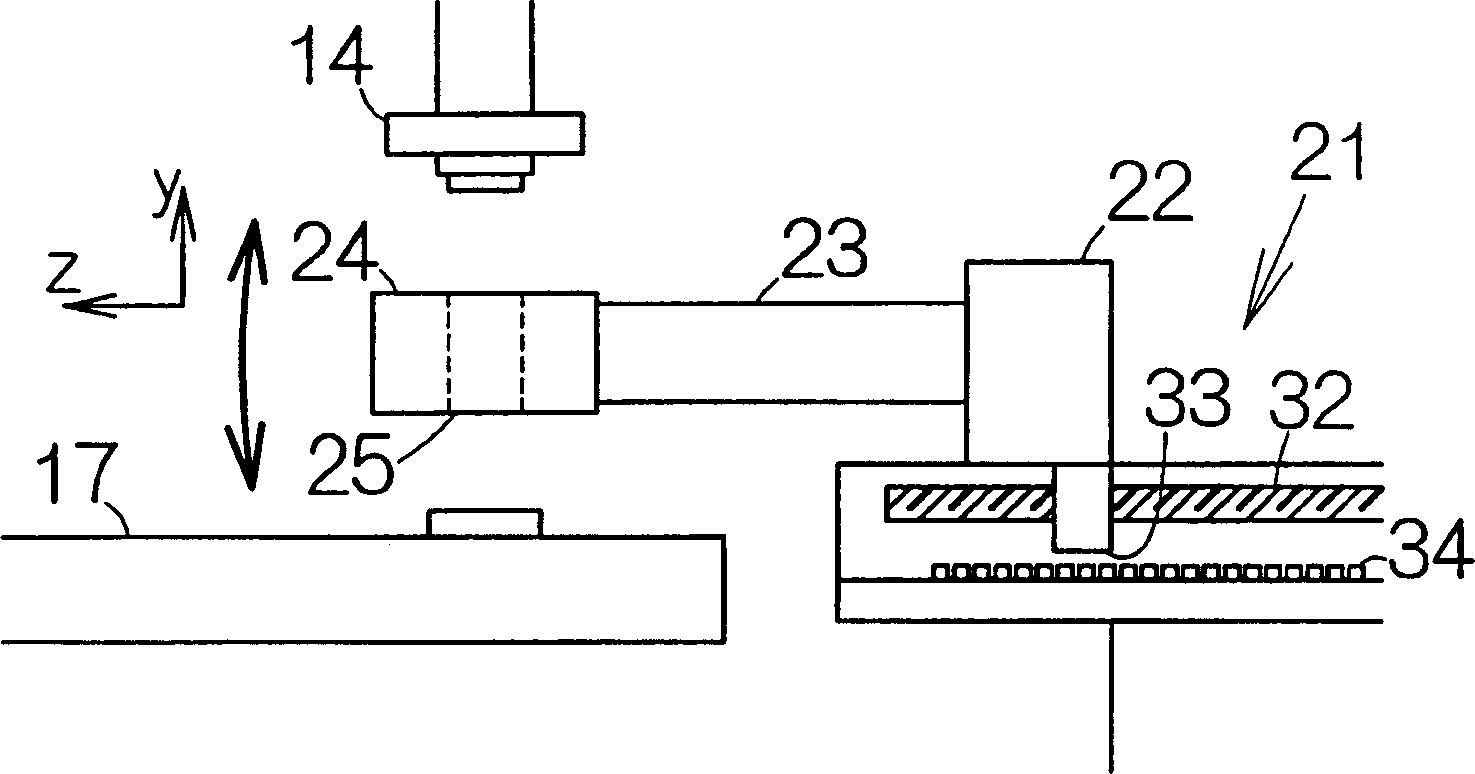

[0018] figure 1 A chip mounter 11 is schematically illustrated as an example of a processing device according to an embodiment of the present invention. The chip mounter 11 includes a table 12 defining an upper flat surface along a predetermined horizontal plane. The table 12 is allowed to move within this horizontal plane. The table 12 is designed to bear a printed circuit board on this upper flat surface.

[0019] Here, an xyz coordinate system is established in the chip mounter 11 . The y-axis of the xyz coordinate system extends in a direction perpendicular to the upper planar surface of the table 12 (ie, perpendicular to the horizontal plane). The table 12 is driven in the x-axis and y-axis directions. The position of table 12 can be identified by x-coordinates and y-coordinates.

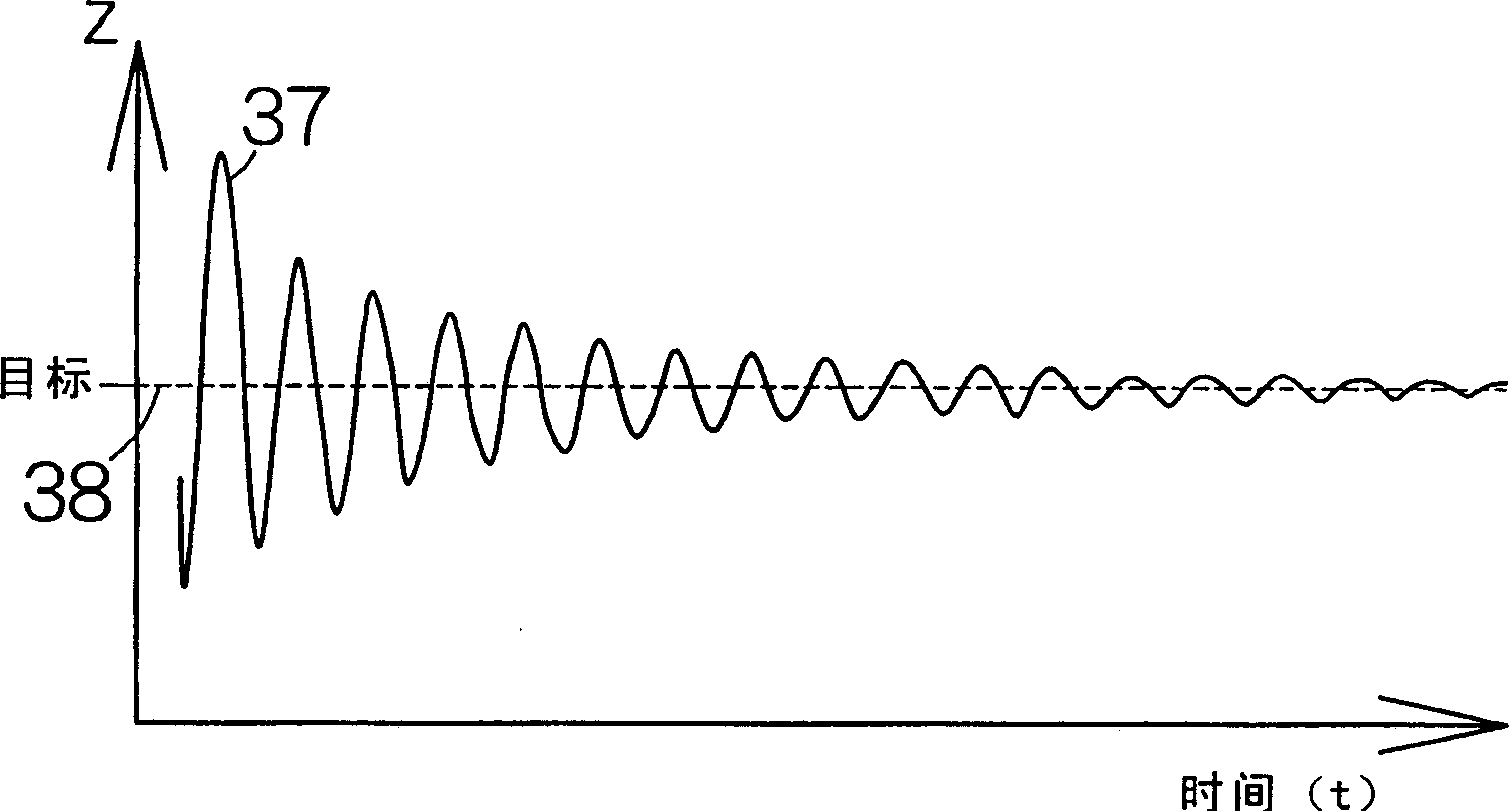

[0020] A pressure device 13 is associated with the table 12 . The pressure device 13 includes an ultrasound head 14 . The ultrasonic head 14 is designed to hold circuit component chips a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com