Patents

Literature

48results about How to "Scientific analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

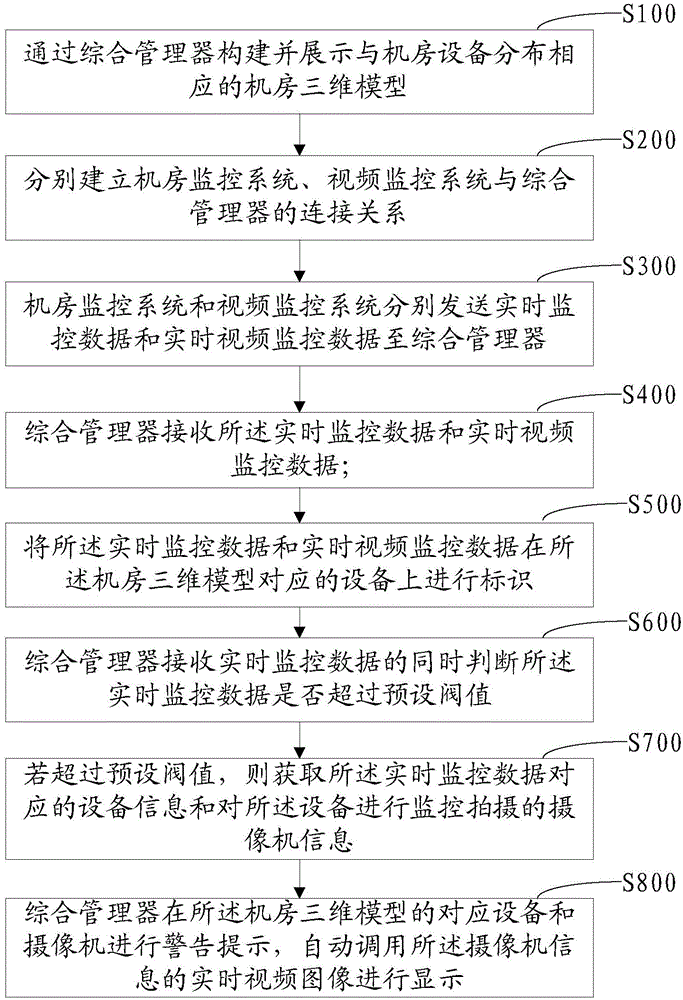

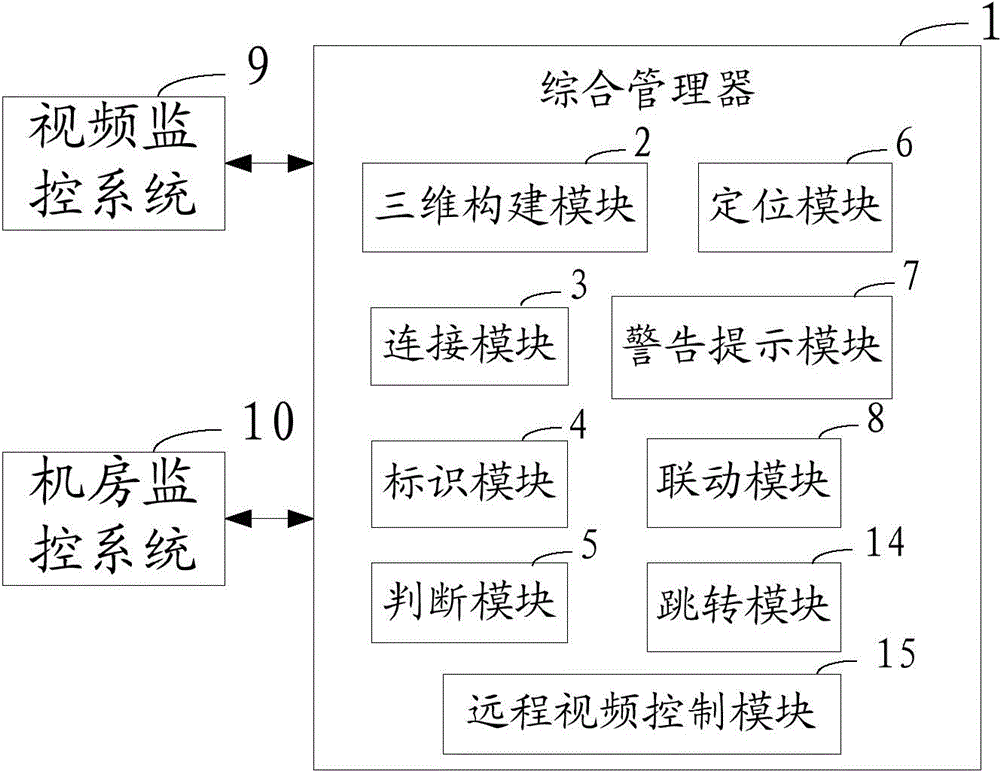

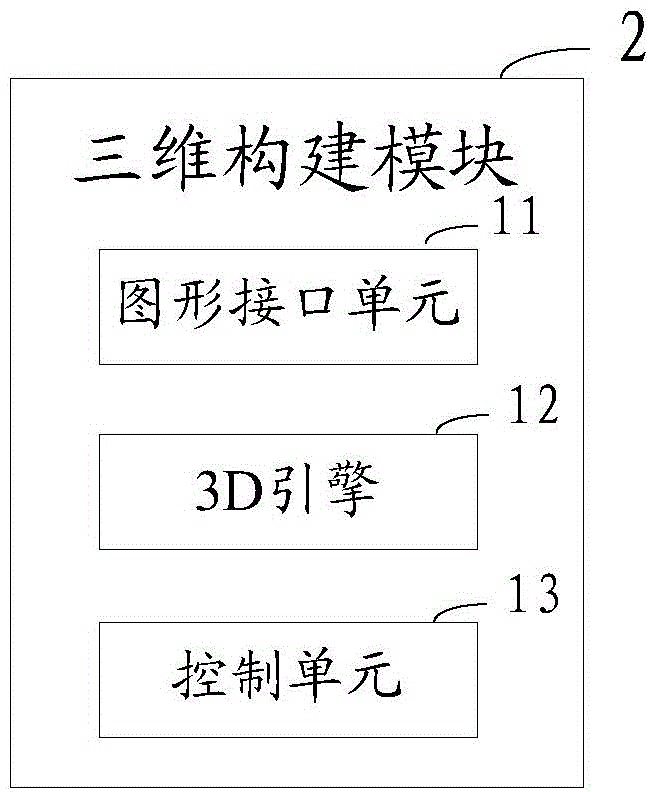

Three-dimensional dynamic monitoring method and system of machine room

ActiveCN104618694AHighly integratedRealize business concentrationClosed circuit television systems3D modellingThree dimensional modelMonitoring data

The invention provides a three-dimensional dynamic monitoring method and a three-dimensional dynamic monitoring system of a machine room. The method comprises the following steps: building and showing a machine room three-dimensional model corresponding to the distribution of machine room equipment through a comprehensive manager; respectively building a connection relation among a machine room monitoring system, a video monitoring system and the comprehensive manager; receiving real-time monitoring data and real-time video monitoring data by the comprehensive manager and identifying on the equipment corresponding to the machine room three-dimensional model; judging whether the real-time monitoring data exceeds a preset threshold value; acquiring equipment information corresponding to the real-time monitoring data and camera information about the monitoring and the shooting of the equipment if the real-time monitoring data exceeds a preset threshold value; warning and prompting the corresponding equipment of the machine room three-dimensional model and displaying by automatically calling real-time video images of the camera information. According to the method and the system, three-dimensional integrated management of the machine room system is realized, and the machine room three-dimensional model is combined with video monitoring, so that business centralization is realized.

Owner:STATE GRID CORP OF CHINA +2

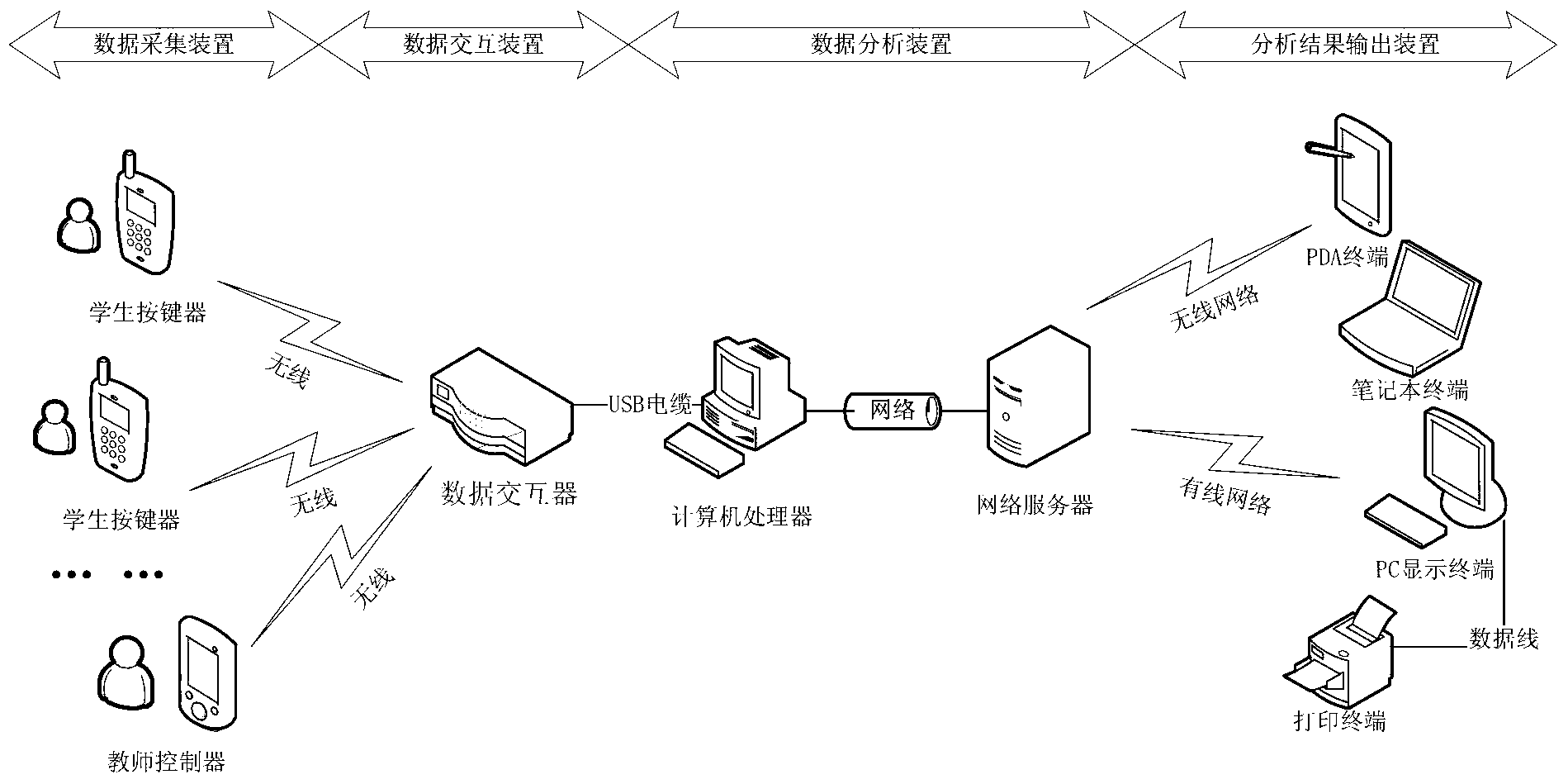

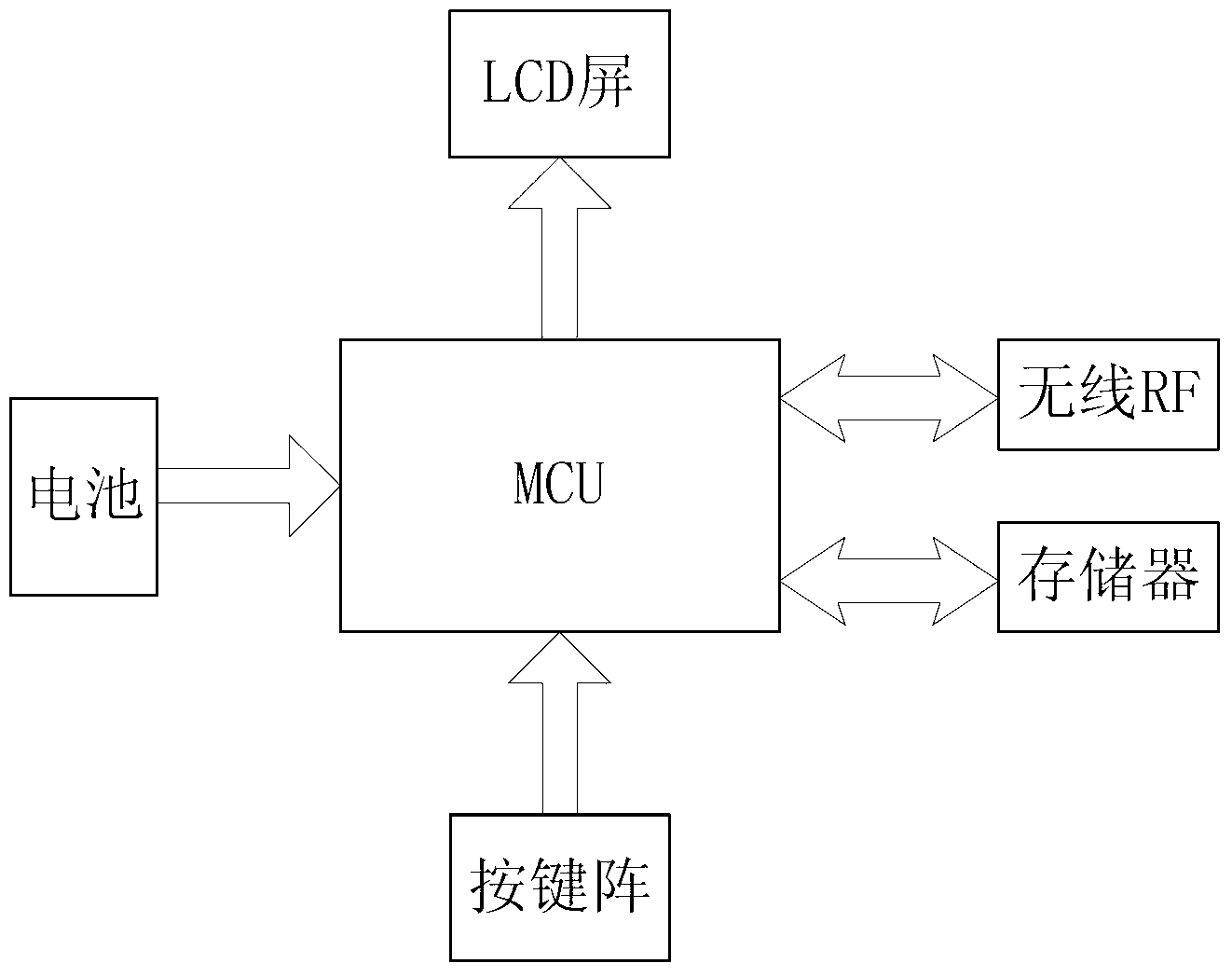

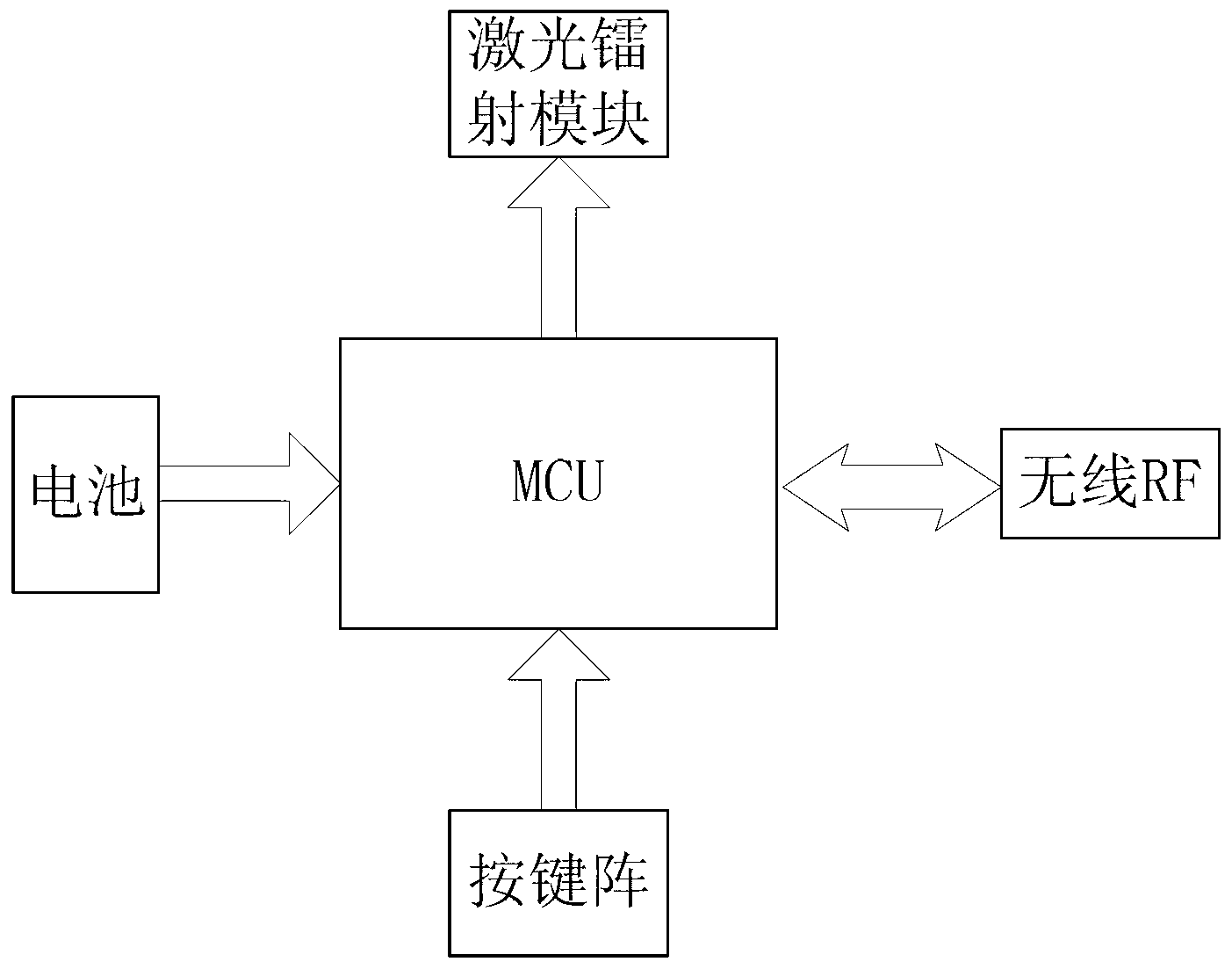

Classroom teaching auxiliary system

InactiveCN103258451AEnhance disciplineStimulate learning initiativeElectrical appliancesData acquisitionInteraction device

The invention provides a classroom teaching auxiliary system which comprises a data collecting device, a data interaction device and a data analyzing device, wherein the data collecting device and the data interaction device are connected in a wireless mode to carry out data transmission, and the data interaction device is connected to the data analyzing device through a data transmission cable. The data collecting device comprises an information collector which is used for checking-in, selecting, grading, voting and electronically raising hands, and at the same time the data collector collects teaching management data. The data analyzing device carries out statistic analysis on the teaching management data which are collected by the data collector, and obtains a teaching quality report. The classroom teaching auxiliary system can increase constraint force on classroom discipline, strengths supervision on teaching quality, arouses learning initiative of students, assists classroom teaching of teachers, solves the problems of style of study and style of teaching in traditional teaching, and continuously improves the teaching quality. The classroom teaching auxiliary system not only can objectively and reliably monitor quality characteristics of the classroom teaching, but also can analyze scientifically and accurately on the basis of monitoring and then provide a more reasonable teaching quality report and a rectification and reform program.

Owner:何凯佳 +1

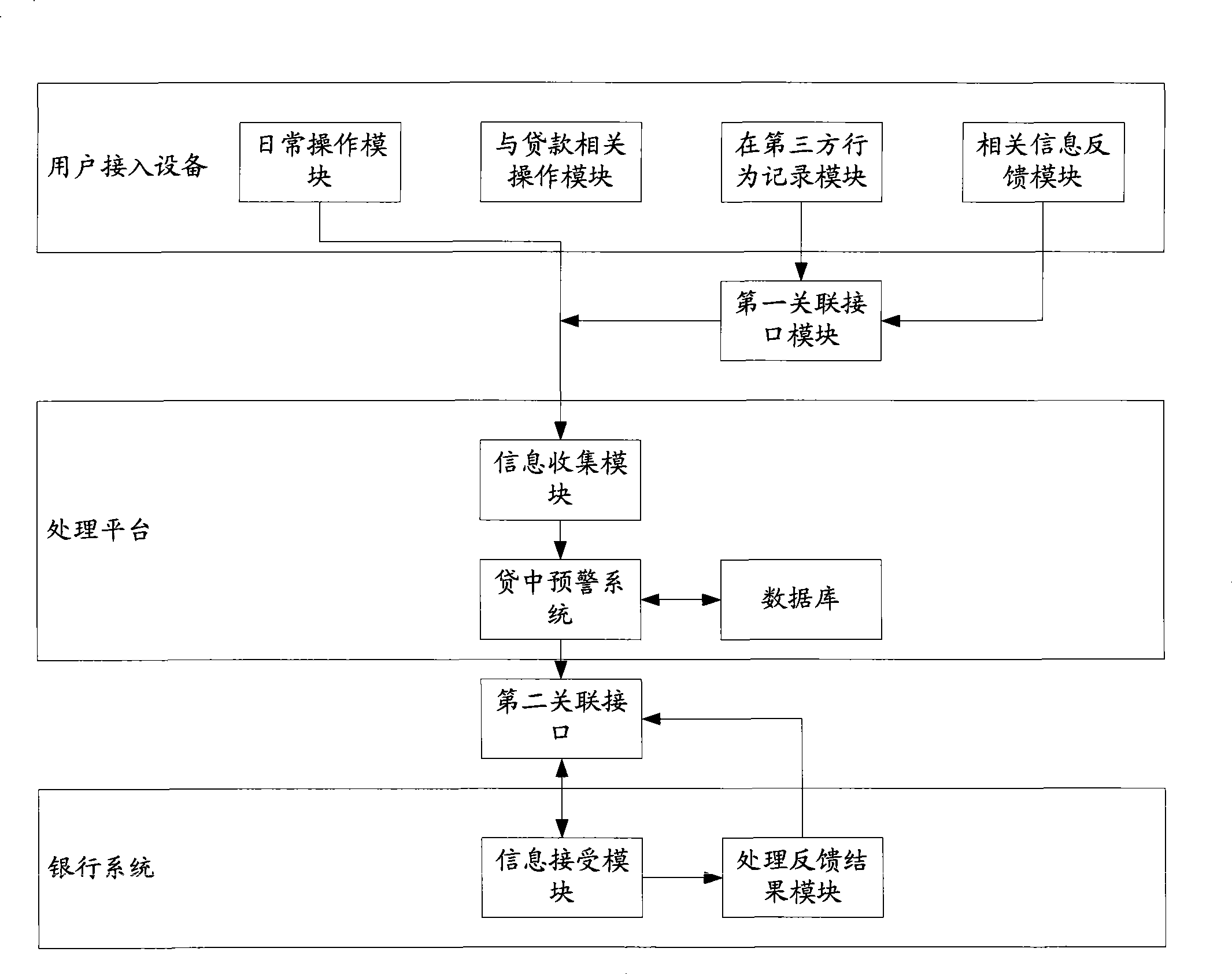

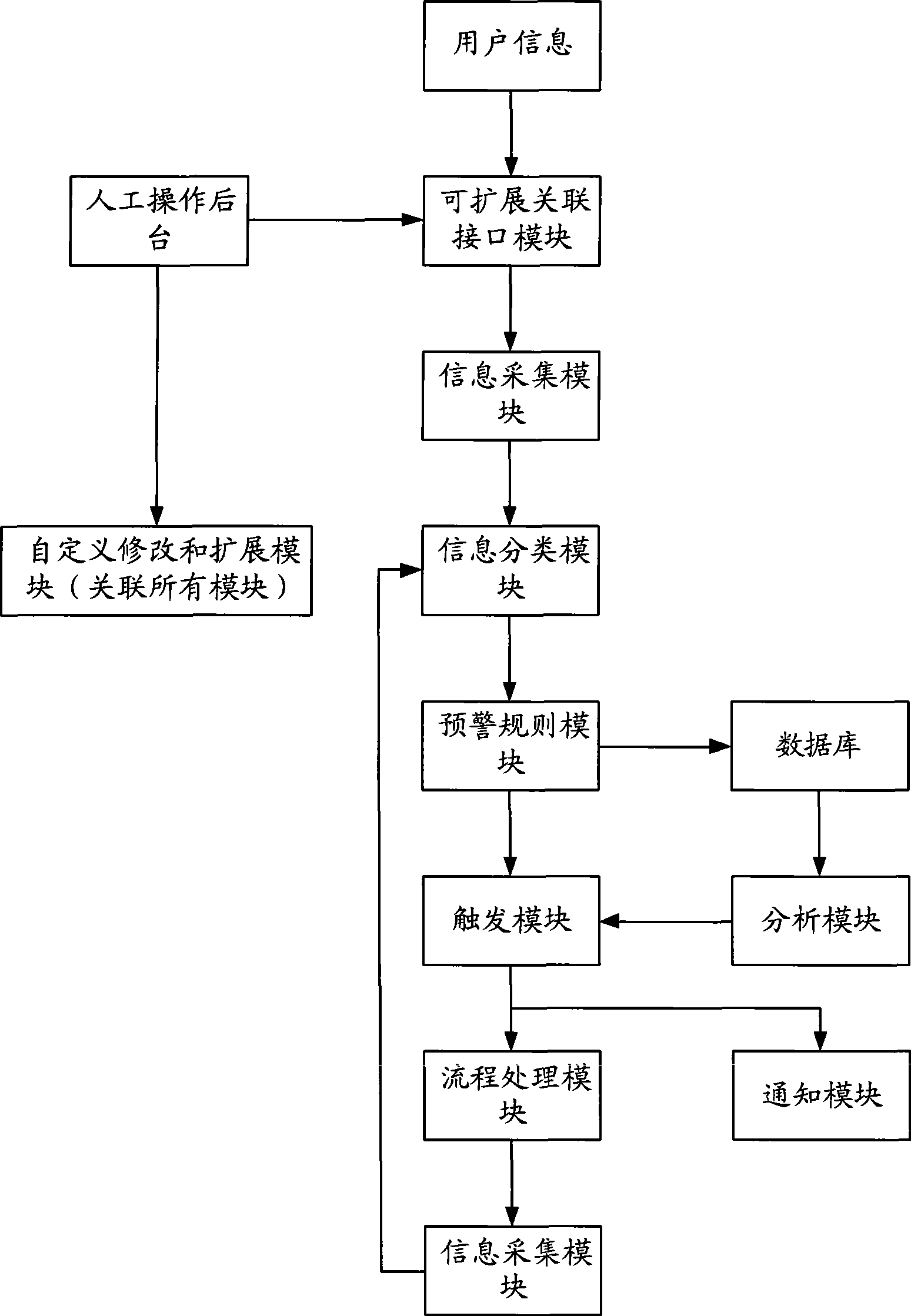

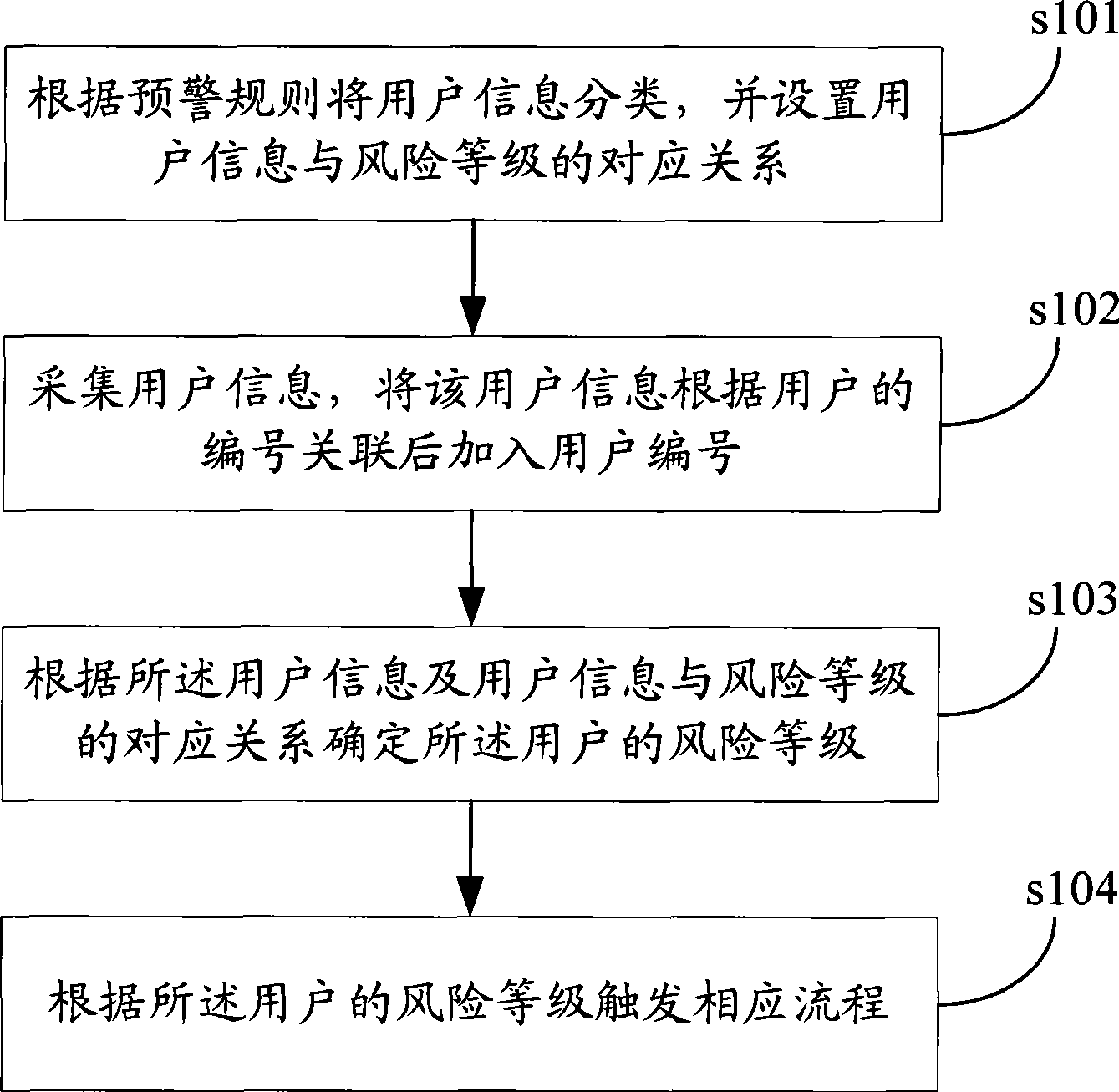

Credit early-warning system and method

InactiveCN101470887AAchieve maintenanceRealize monitoringFinanceEarly warning systemComputer science

Owner:ALIBABA GRP HLDG LTD

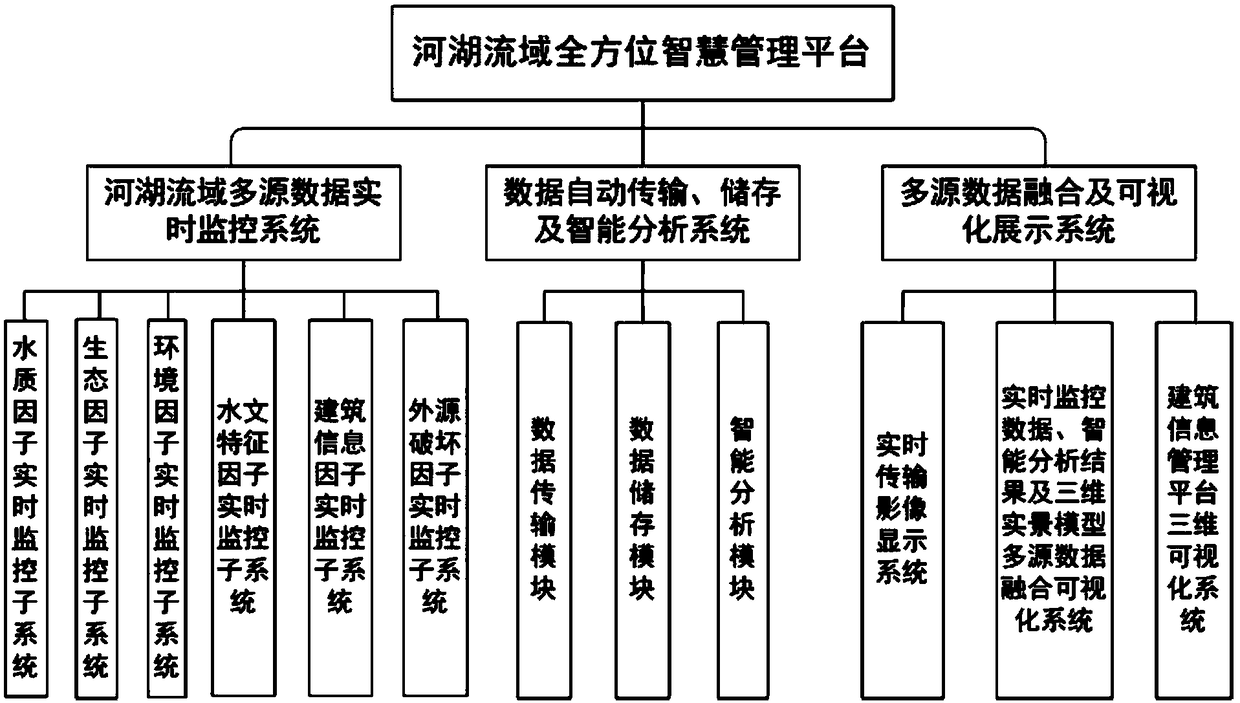

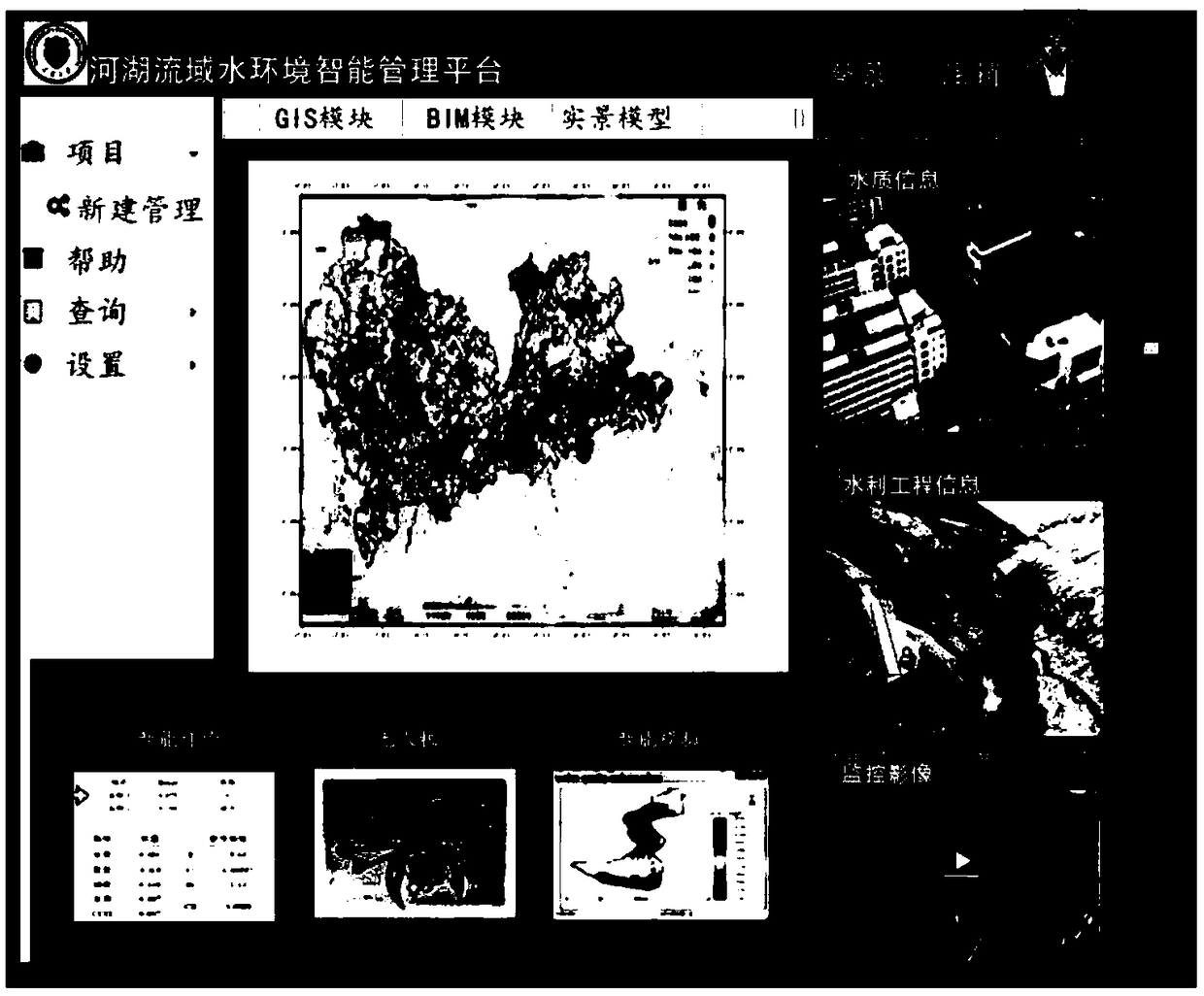

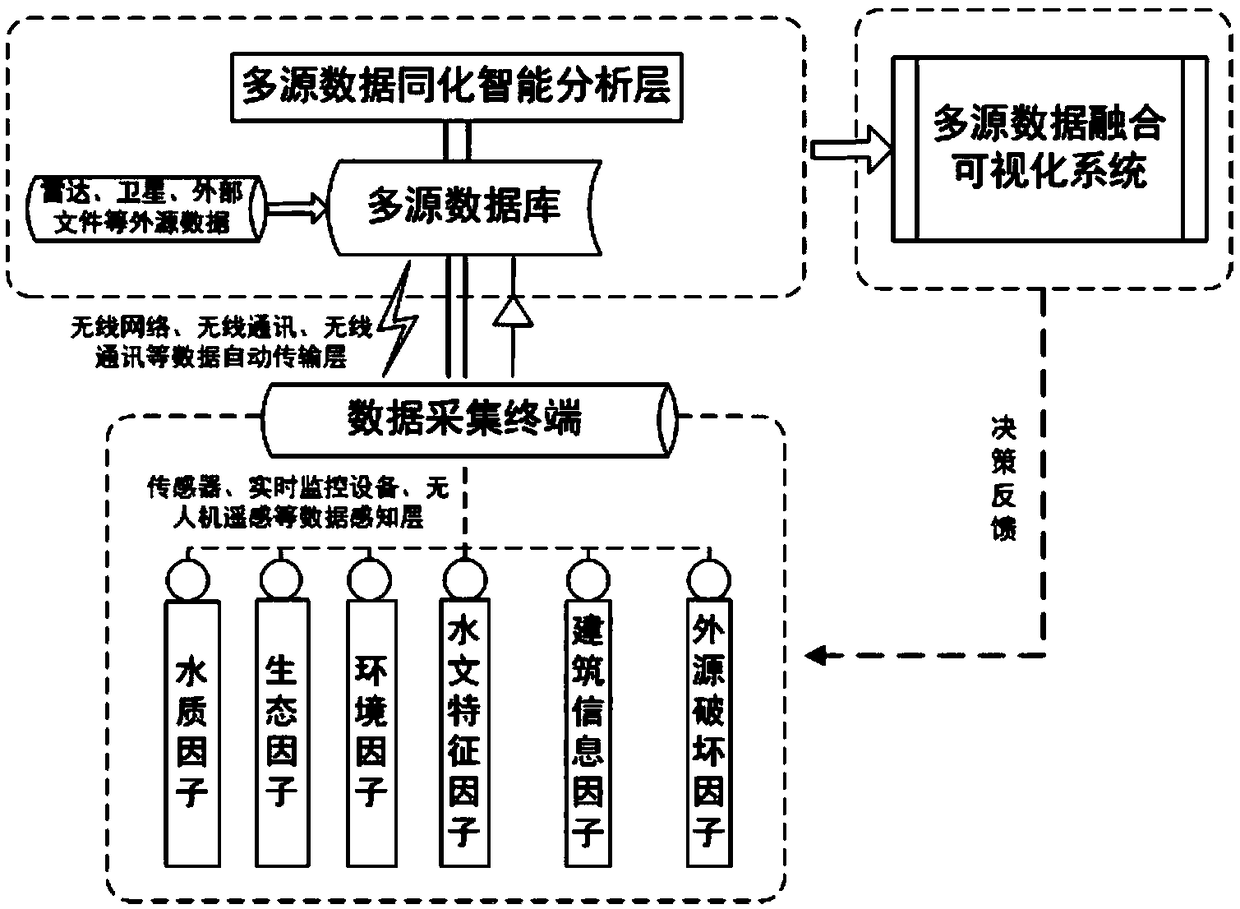

Water environment intelligent management platform for river and lake watershed

InactiveCN109242291ARealize intelligent simulation predictionRealize evaluationGeneral water supply conservationForecastingWatershed managementTotal nitrogen

The invention belongs to the technical field of watershed management and provides a water environment intelligent management platform for river and lake watershed. The system combines the real-time monitoring system of multi-source data of river and lake basin, automatic data transmission, storage and intelligent analysis system, the multi-source data fusion visualization system on the same platform, aiming at realizing more comprehensive, scientific and efficient management of the water environment of the river and lake basin. The invention relates to a water environment intelligent management method of the river and lake watershed, which comprises the following steps of: real-time monitoring water quality factor, ecological factor, environmental factor, hydrological characteristic factor, building information factor and external destruction factor. Water quality factor is subjected to remote sensing inversion by multi-spectral UVA, the detecting indexes includ total nitrogen, total phosphorus, ammonia nitrogen, chemical requirement COD, chlorophyll, and the distribution of water quality is obtained by post-processing analysis. The real-time monitoring of ecological factors is toobtain orthophoto images through UAV remote sensing. The invention is mainly applied to environment monitoring occasions.

Owner:TIANJIN UNIV

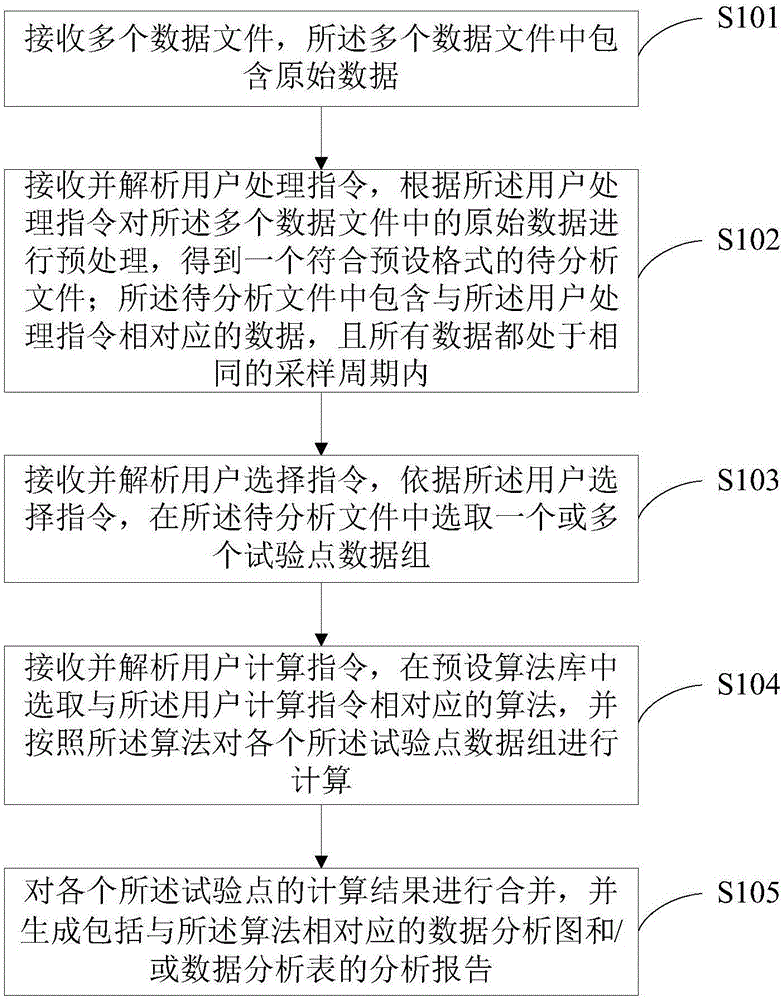

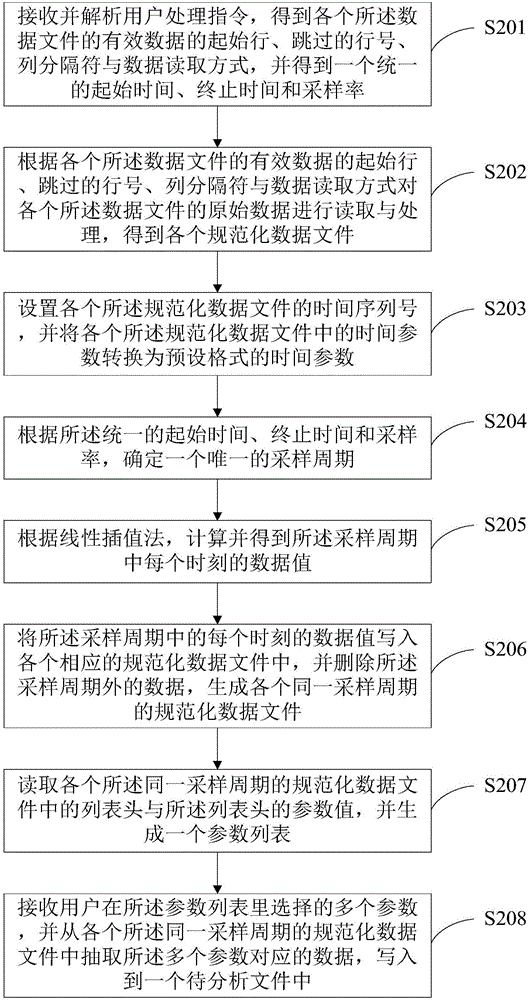

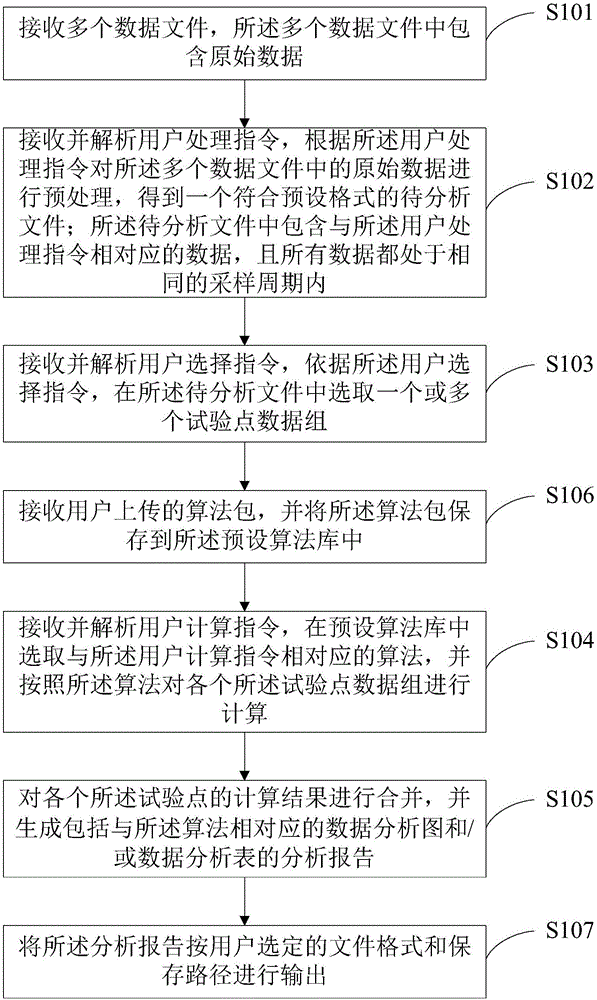

Data analyzing method and system

ActiveCN106484803AReasonable handlingReasonable analysisFile access structuresSpecial data processing applicationsData fileData profiling

The invention provides a data analyzing method and system. The data analyzing method comprises the following steps: receiving and resolving a user processing command, and preprocessing data files of different sources and different forms to obtain a file to be analyzed conforming to a preset format, wherein parameters needing to be analyzed can be selected according to specific demands of a user, and all data are in the same sampling period, so that the times of the data to be analyzed are synchronized; receiving and resolving a user selection command, and selecting one or more test point data groups from the file to be analyzed according to the user selection command; selecting an algorithm corresponding to the user calculation command from a preset algorithm base, and calculating the test point data groups according to the algorithm; and lastly, combining calculation results of test points, and generating an analysis report including a data analysis diagram and / or a data analysis table corresponding to the algorithm. Based on the technical scheme provided by the invention, test data can be processed and analyzed reasonably, scientifically and regularly.

Owner:BEIJING RUNKE GENERAL TECH

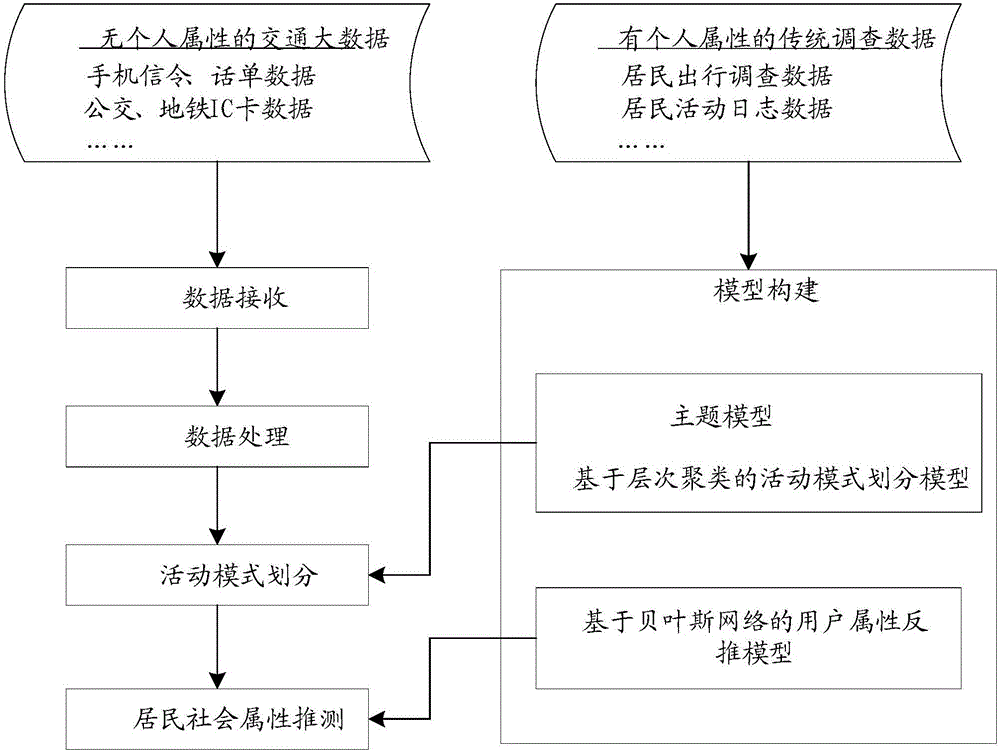

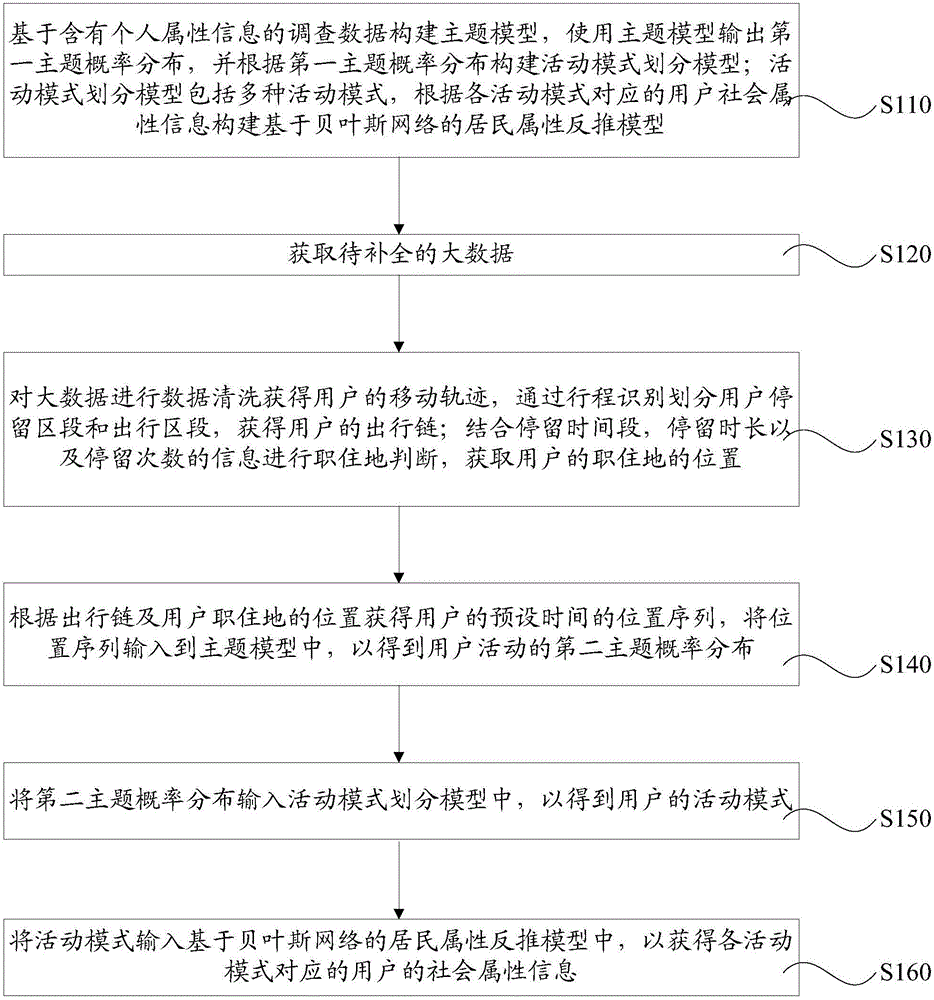

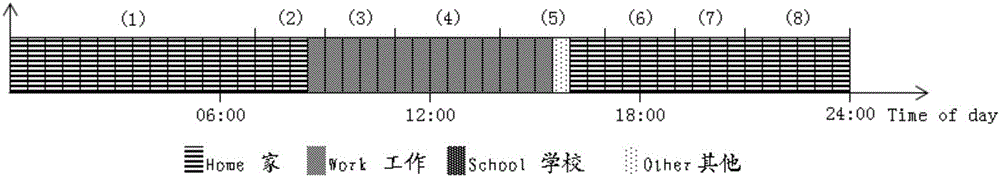

User activity mode dividing and attribute speculating method

InactiveCN107527313AOvercome the defect of single content in the activity modeEasy to completeData processing applicationsCharacter and pattern recognitionSubject matterComputer science

The invention relates to a user activity mode dividing and attribute speculating method, and the method comprises the steps: constructing a theme model, an activity mode dividing model and a Bayesian-network-based resident attribute backstepping model based on investigation data comprising personal attributes and travel information; obtaining to-be-complements big data; carrying out the processing of big data in the theme model and the activity mode dividing model, so as to obtain activity modes of users; inputting the activity modes into the Bayesian-network-based resident attribute backstepping model, so as to obtain the social economy attribute information, corresponding to each mode, of the users. According to the invention, the number of activity modes is six, so the method can achieve the complementation of the social economy attribute information of all users, and can achieve the scientific and convenient analysis and statistics of the number of individuals on a road at each time period of a day. Meanwhile, whether each user specifically takes a bus or drives a car can be further judged through the social economy attribute information of the individuals, thereby providing the important reference basis for the urban traffic planning and traffic demand prediction.

Owner:TONGJI UNIV

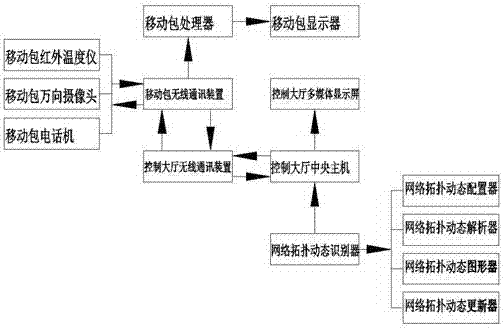

Device for dynamically identifying network equipment topology of intelligent substation based on MAC address matching

ActiveCN107124319AMonitoring statusEasy maintenanceData switching networksSmart substationGraphical query

The invention discloses a device for dynamically identifying the network equipment topology of an intelligent substation based on MAC address matching. The device comprises a dynamic network topology identifier; the dynamic network topology identifier comprises a dynamic network topology configurator, a dynamic network topology analyzer, a dynamic network topology graphical device and a dynamic network topology updater; the dynamic network topology identifier is connected with a control hall central host of the substation; a control hall multi-media display screen displays the topological state of the whole substation network system; the control hall central host is connected with a mobile packet wireless communication device through a control hall wireless communication device; and real-time dynamic graphical query of the network equipment topology can be realized through a mobile packet. By means of the device disclosed by the invention, the topological graph of an online switch and the states of various ports in an intelligent substation network can be monitored intuitively in real time; the topological relationship of equipment can be queried on the scene in real time through the mobile packet; therefore, remote judgement and prediction on equipment failure can be realized; and the efficiency is increased.

Owner:GUIZHOU POWER GRID CO LTD

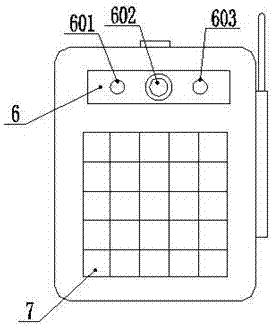

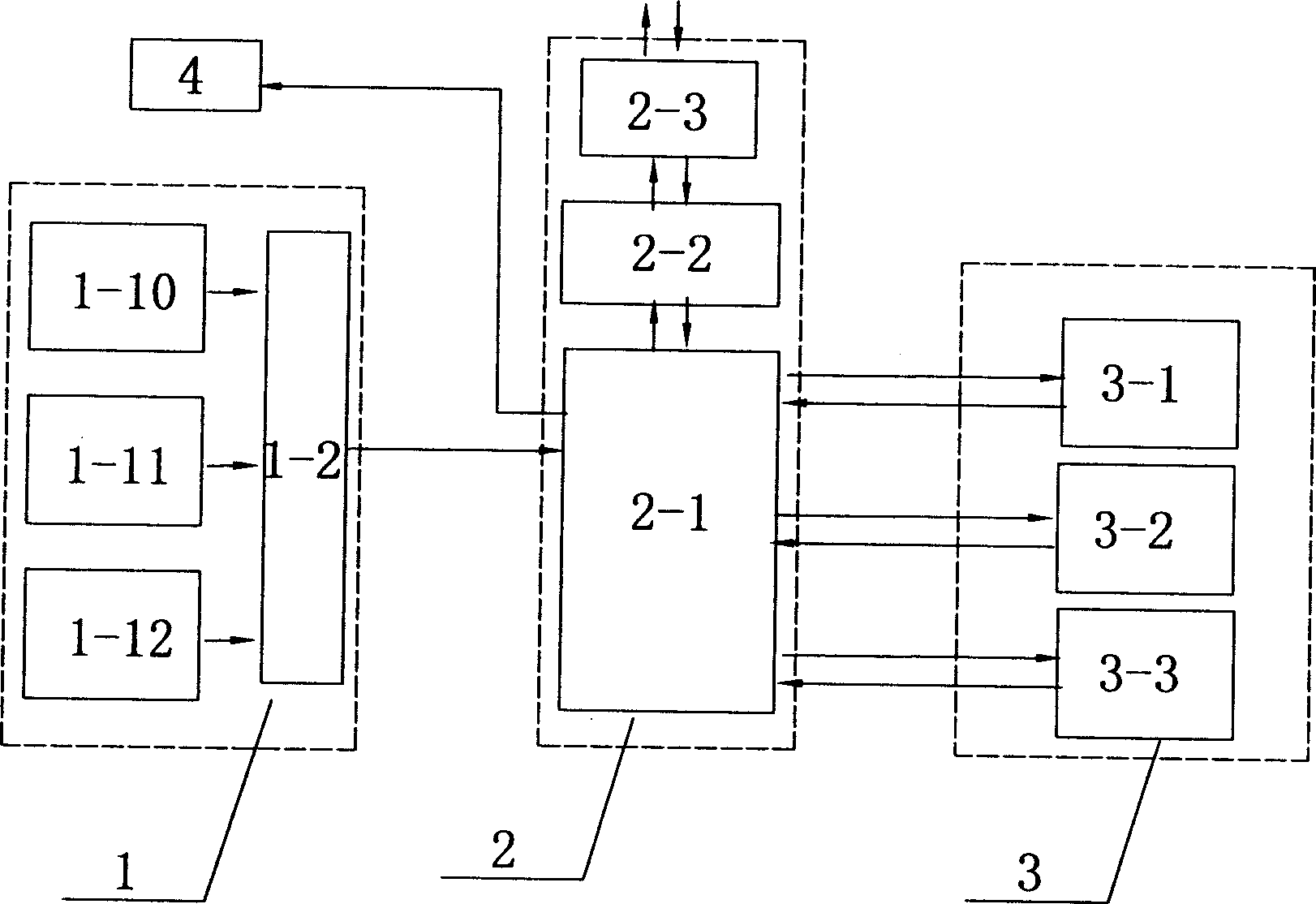

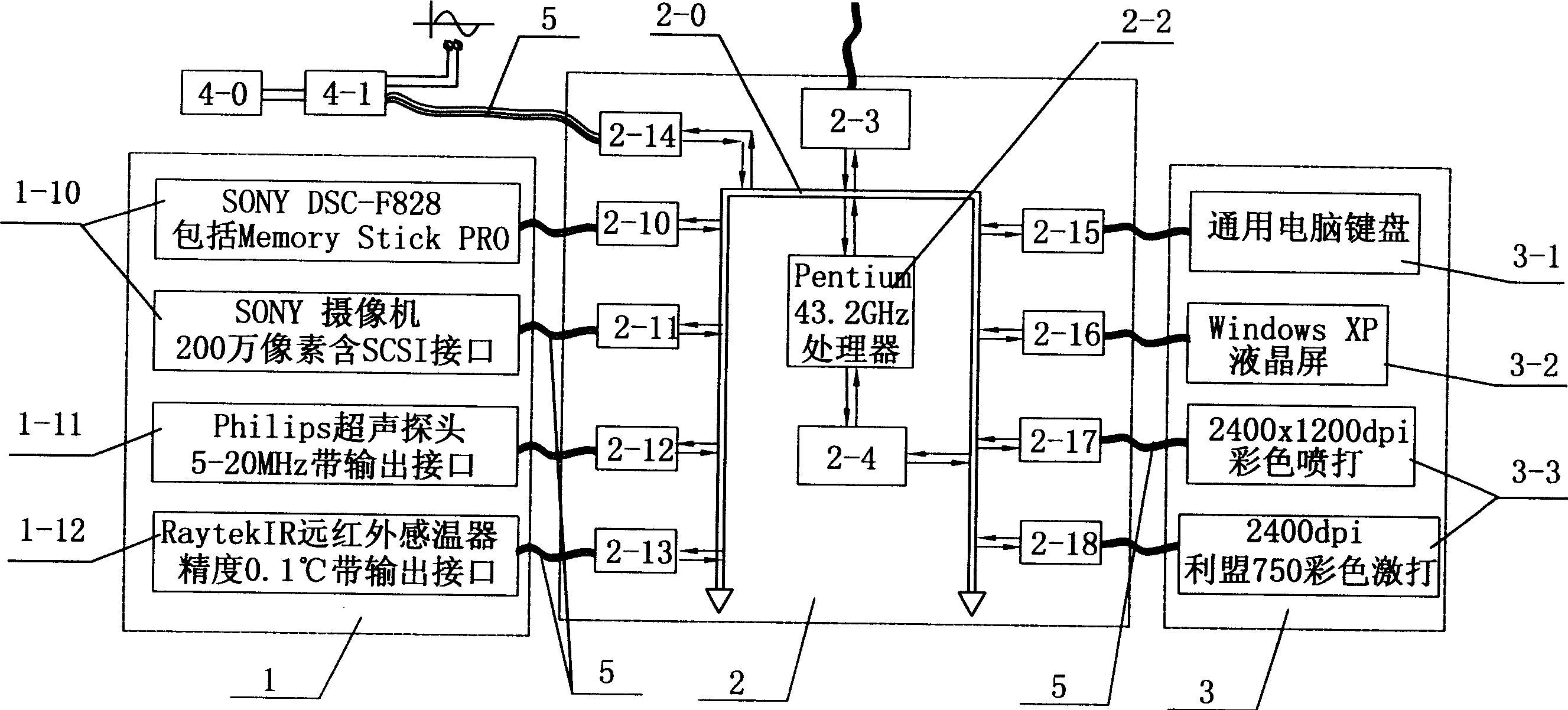

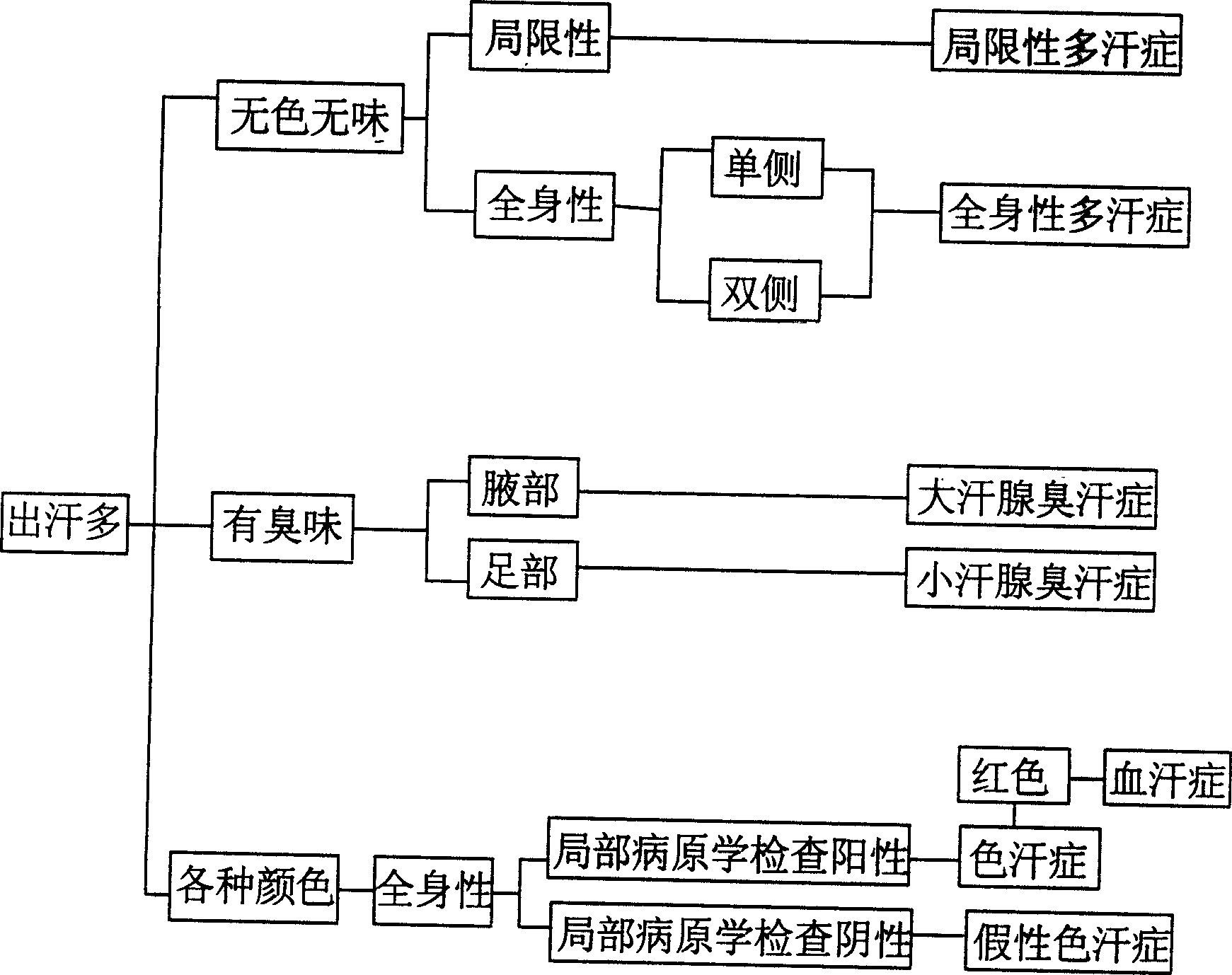

Instrument system for real-time detecting and assistant diagnosing and treating skin diseases and venereal diseases

InactiveCN1614617AObjective clinical featuresObjective Detection/SamplingSpecial data processing applicationsReal time analysisHuman–computer interaction

An instrument system of real time detection comprises real time collection component of clinical data for dermatosis and venereal disease, real time analysis component of clinical data, man-machine interactive device, electric light source, computer set, optical imaging detector, acoustic detector and temperature tester.

Owner:张宏 +1

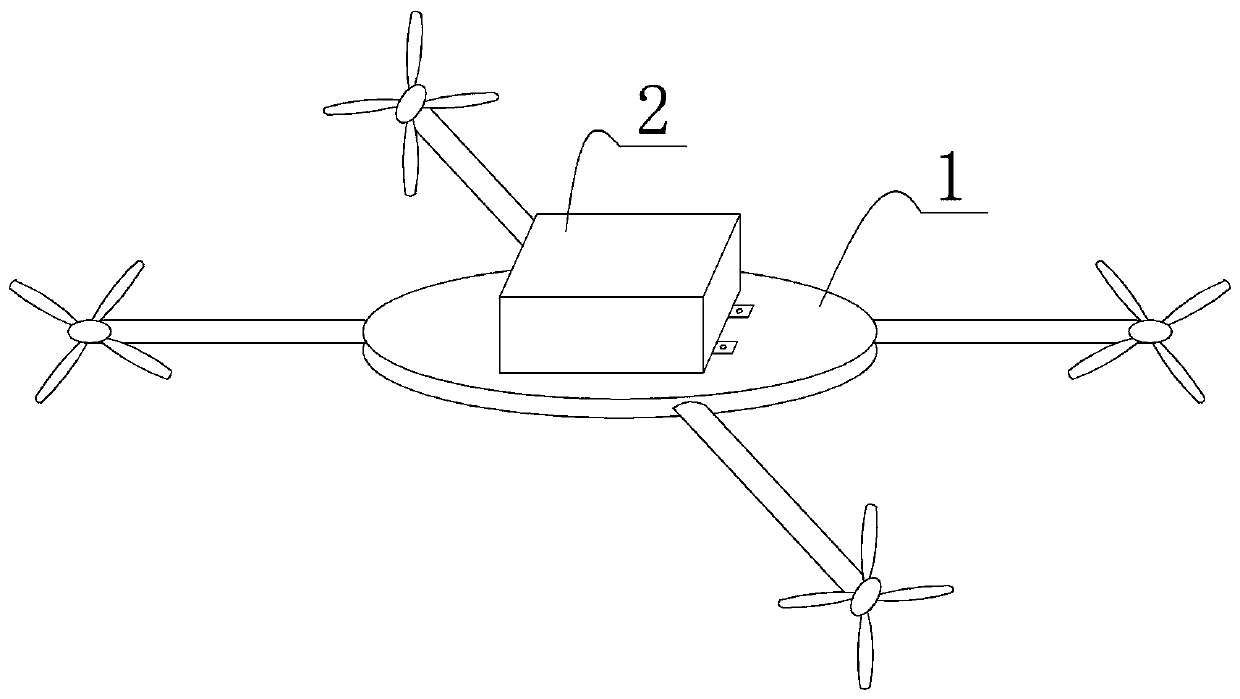

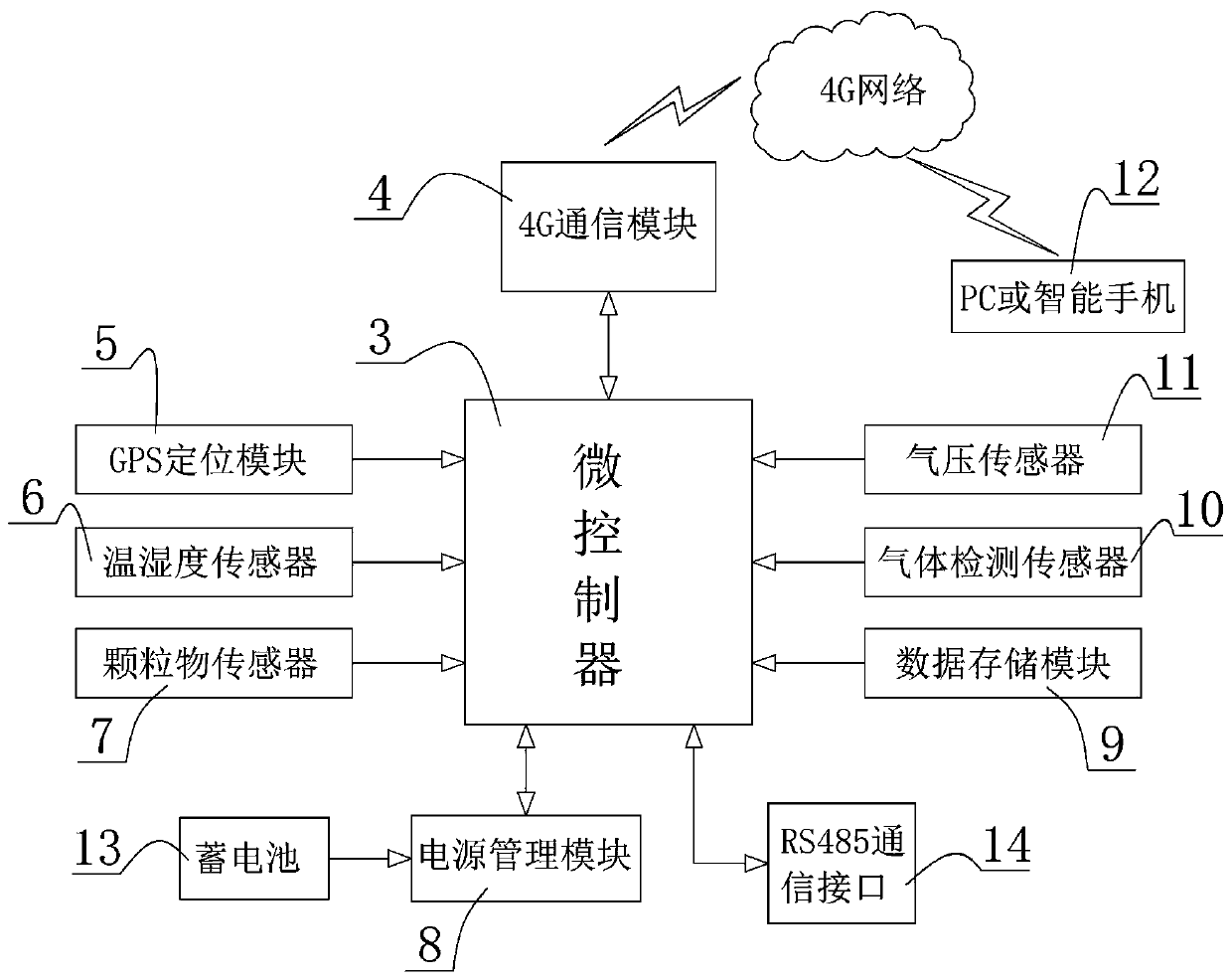

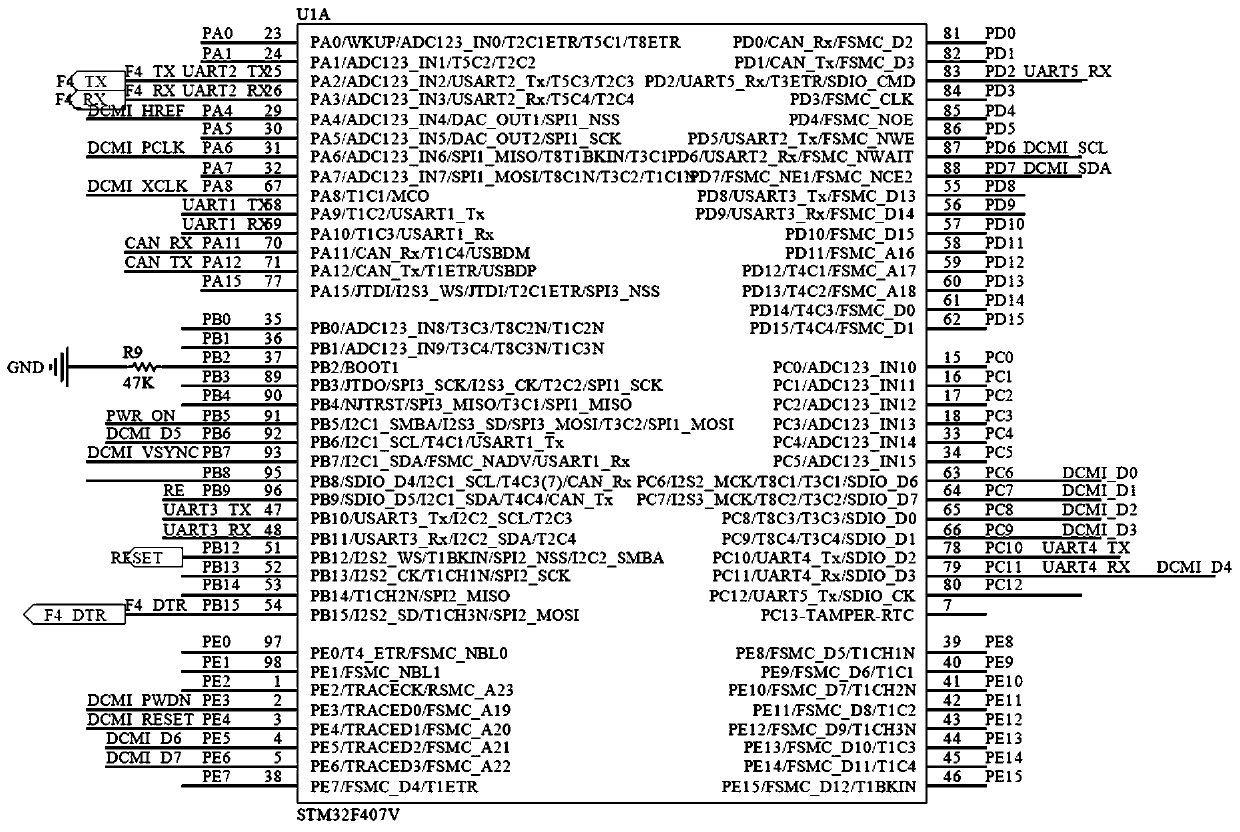

Unmanned-aerial-vehicle-based environment monitoring device

InactiveCN109855685ADrawbacks of change detectionScientific analysisMeasurement devicesMicrocontrollerParticulates

The invention relates to an unmanned-aerial-vehicle-based environment monitoring device comprising a multi-rotor unmanned aerial vehicle and an environment monitoring unit. The environment monitoringunit includes a microcontroller, a 4G communication module, a GPS positioning module, a temperature and humidity sensor, a particulate matter sensor, an air pressure sensor, a data storage module anda power management module, wherein the 4G communication module, the GPS positioning module, the temperature and humidity sensor, the particulate matter sensor, the air pressure sensor, the data storage module and the power management module are connected with the microcontroller. The microcontroller transmits obtained latitude, longitude, altitude, temperature, humidity, suspended particulate matter concentration and atmospheric pressure information to a PC or a smart phone via the 4G communication module. According to the unmanned-aerial-vehicle-based environment monitoring device, the data collected in a low-altitude area are transmitted to the PC or smart phone via the 4G network and the collected data are stored in a high-altitude area; and the stored data are outputted after the unmanned aerial vehicle returns, so that the corresponding personnel carries out scientific and reasonable analysis on the environmental condition conveniently and the scientific and reasonable measures tothe polluted weather are provided. The unmanned-aerial-vehicle-based environment monitoring device has the obvious beneficial effects and is suitable for application and promotion.

Owner:BINZHOU UNIV

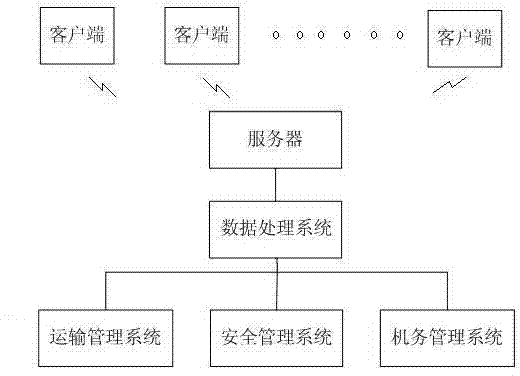

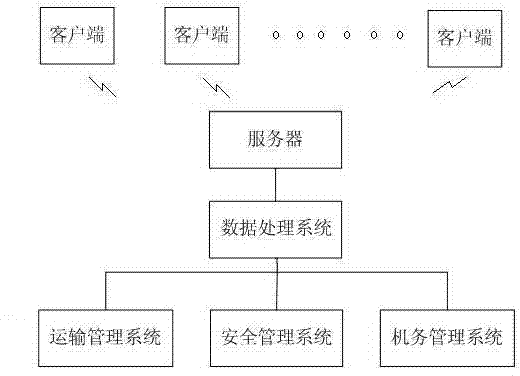

Public transportation management system

InactiveCN102254243ATimely analysisAccurate analysisData processing applicationsTime informationData processing system

The invention discloses a public transportation management system. The public transportation management system comprises: a server, clients, a transportation management system, a maintenance management system, a safety management system and a data processing system. The data processing system respectively carries out a data transmission with the server, the maintenance management system, the transportation management system and the safety management system. The clients are connected with the server. The public transportation management system of the invention accords with an actual management framework of an urban public transportation. Real-time information monitoring can be realized. Database can be generated. Timely, accurate and scientific statistics and analysis of data of each department, each position and personnel can be performed. Therefore, objective and fine management can be reached.

Owner:苏州蓝水软件开发股份有限公司

Autocontrol type cigarette case capable of assisting smoking cessation

The invention relates to an autocontrol type cigarette case capable of assisting smoking cessation. Single-person or multi-person control smoking cessation can be achieved. The autocontrol type cigarette case capable of assisting smoking cessation comprises a software platform and a smoking cessation cigarette case body. The software platform is used for transmitting instructions and analyzing and processing data so that the smoking cessation process of a user can be guided. The smoke cessation cigarette case body is composed of a control system, a data collecting system, an execution switch part and a cigarette containing area. According to the autocontrol type cigarette case capable of assisting smoking cessation, single-person control smoking cessation can be achieved when a smoking cessation person is firm in mind, multi-person control smoking cessation can be achieved when smoking cessation persons are weak in willpower, the smoking cessation persons can communicate with one another and encourage one another, and the possibility of smoking cessation successes is greatly improved.

Owner:李俊伟

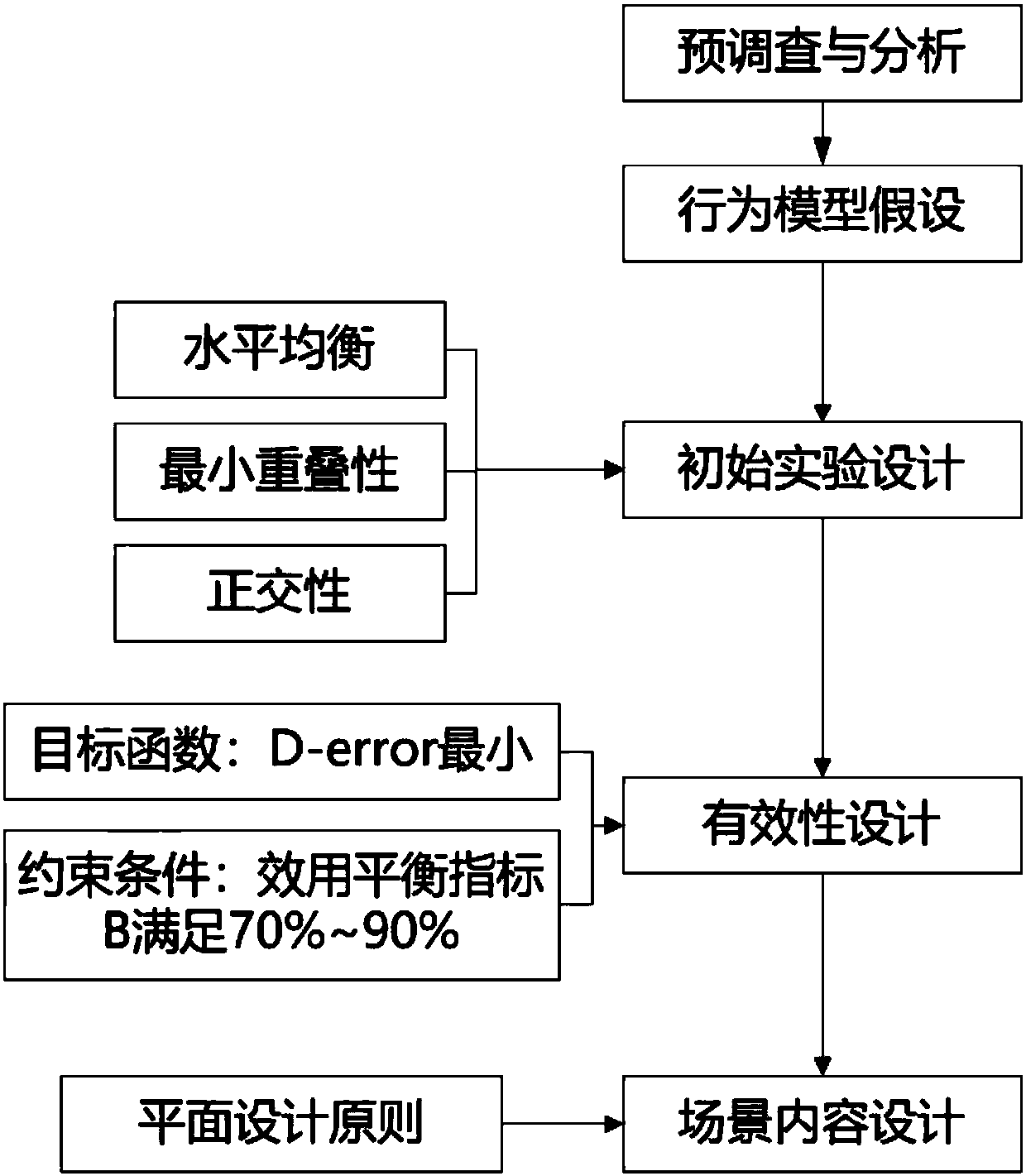

Multi-mode traffic travel questionnaire survey design method based on D-error efficient-design

InactiveCN108564396AImprove the efficiency of obtaining informationApplication advantages are obviousMarket data gatheringTravel modeSimulation

The invention relates to a multi-mode traffic travel questionnaire survey design method based on D-error efficient-design. The method includes the following steps: 1) collecting travel behavior information; 2) determining multi-mode traffic travel, and selecting a behavior model, influencing factors in the model and parameter level values; and 3), constructing traffic scenes for selection in travel on the basis of a D-Error efficient-design principle, wherein the traffic scenes are used as survey items in a questionnaire survey, and include traffic travel modes with the different parameter level values. Compared with the prior art, the method can effectively improve information acquisition efficiency of SP survey scenes, can obtain more survey information under lower test quantity, has thegreat application advantages for SP survey design of all complex scenes, and has the advantages of originality, scientificalness, practicability and the like.

Owner:TONGJI UNIV

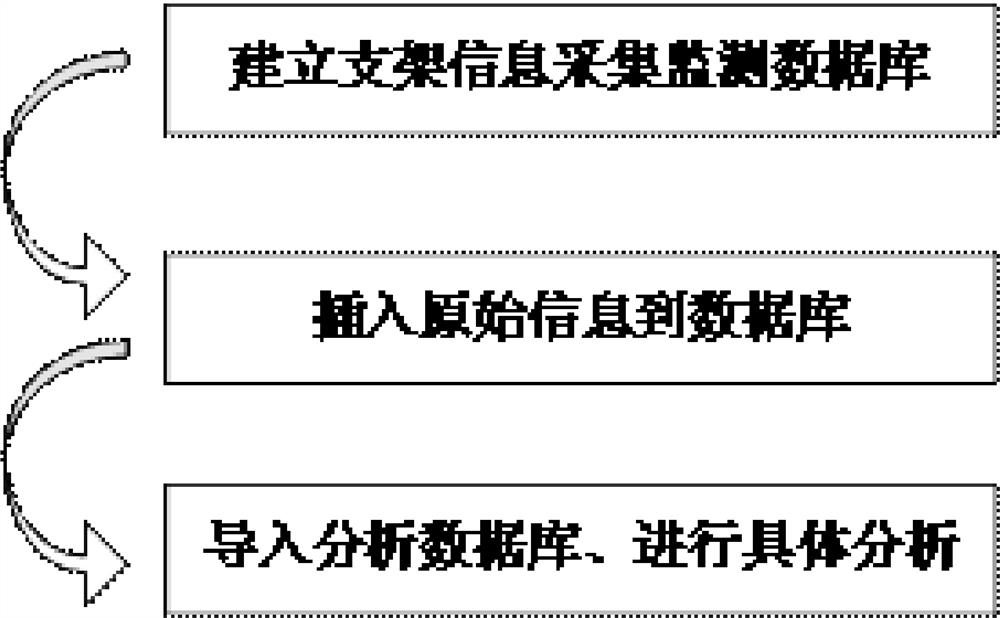

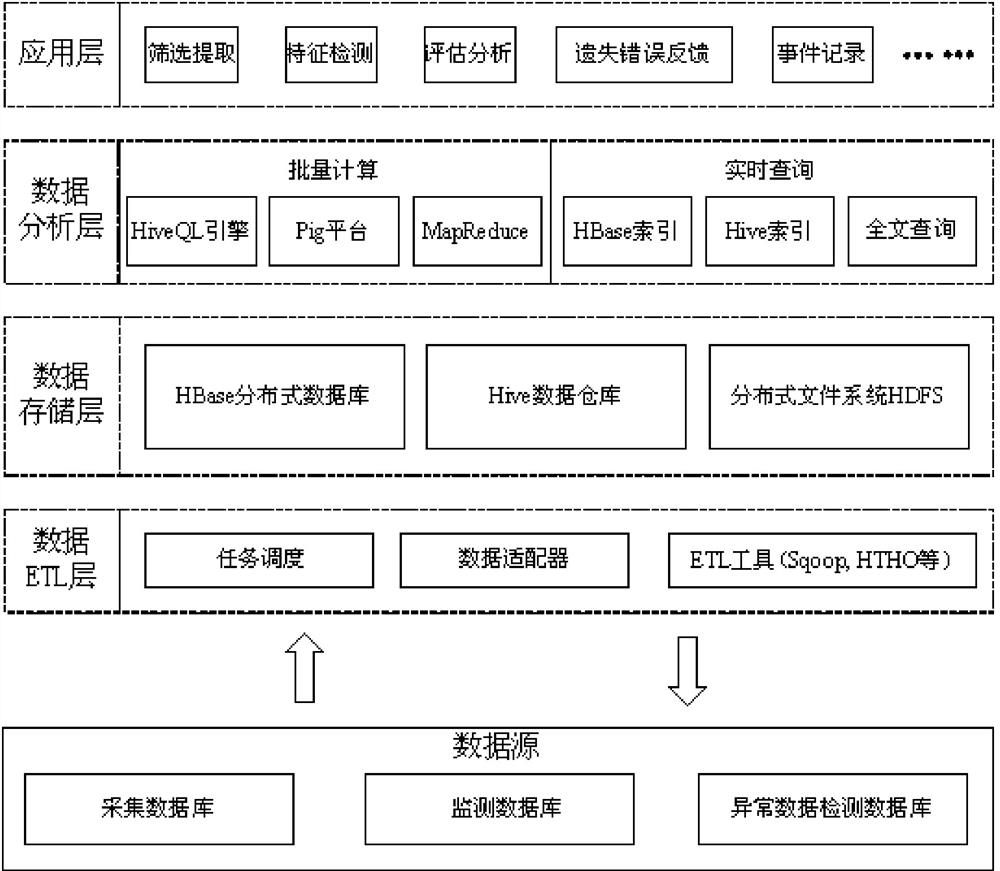

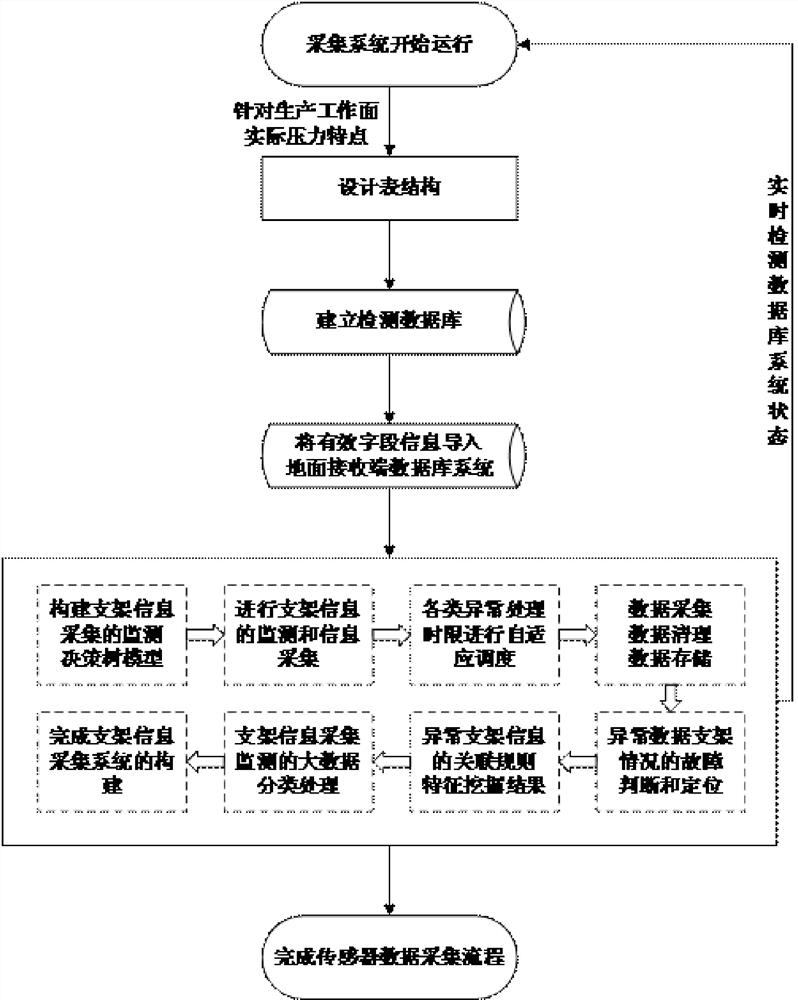

Intelligent fully mechanized coal mining face electro-hydraulic control support data collecting and processing method

ActiveCN112576312AAccurate collectionPrevent leakageMining devicesMine roof supportsData profilingInformation Harvesting

The invention discloses an intelligent fully mechanized coal mining face electro-hydraulic control support data collecting and processing method, and belongs to the technical field of intelligent fully mechanized coal mining face equipment. The method comprises the steps that 1, a monitoring database for support information collection is established; 2, support information is put into a relationalonline database; and 3, support information collection and distribution are completed. Accordingly, electro-hydraulic control hydraulic support data can be collected accurately and timely, the phenomena of missing transmission, retransmission and untimely transmission are avoided, and reliable support is provided for subsequent data analysis work.

Owner:CHINA UNIV OF MINING & TECH

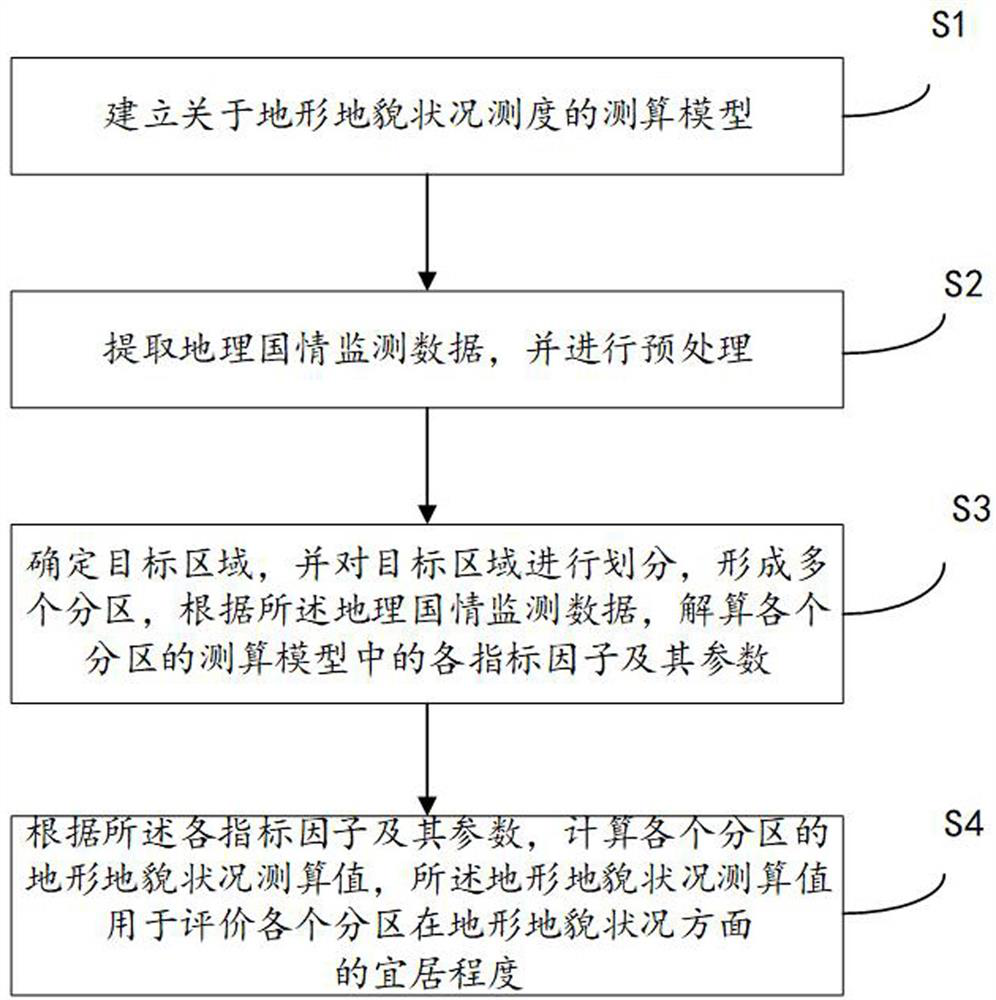

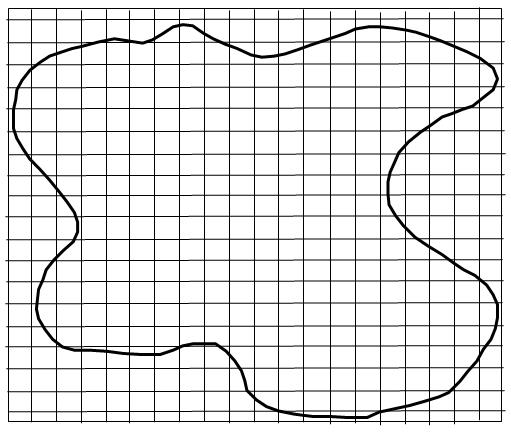

Landform condition measurement method and device

ActiveCN113919185AObjective analysisScientific analysisImage analysisDesign optimisation/simulationData miningLandform

The invention discloses a landform condition measurement method and device. The method comprises the following steps that: a measurement and calculation model about landform condition measurement is established; geographic national condition monitoring data are extracted and preprocessed; a target area is determined, the target area is divided to form a plurality of subareas, and according to the geographic national condition monitoring data, each index factor and parameter thereof in the measurement and calculation model of each subarea are calculated; and according to each index factor and the parameter thereof, a topographic and geomorphic condition measurement value of each subarea is calculated, wherein the topographic and geomorphic condition measurement value is used for evaluating livable degree of each subarea in the aspect of topographic and geomorphic conditions. The method can make full use of existing geographical condition monitoring data, and scientifically, objectively, efficiently and quantitatively analyze the relative conditions of landforms of all regions from the perspective of human production and life livability.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

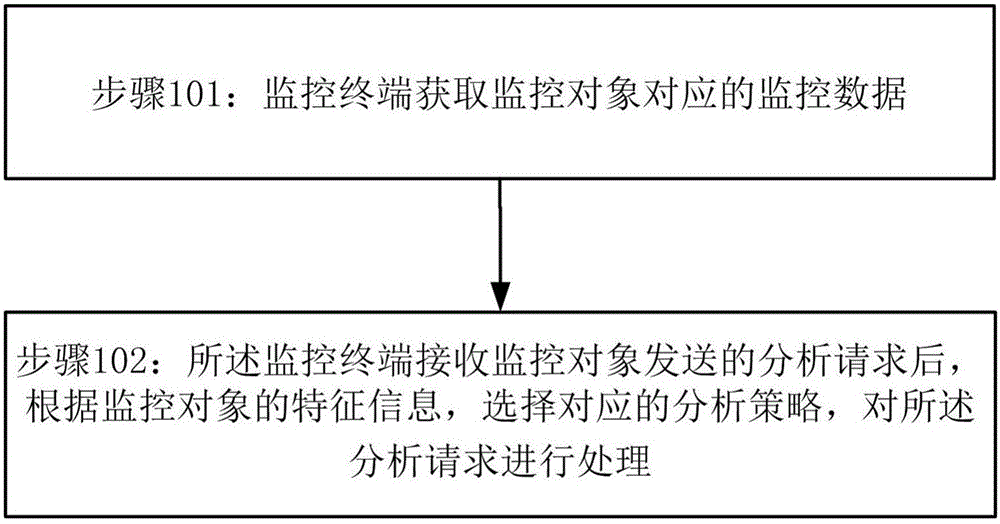

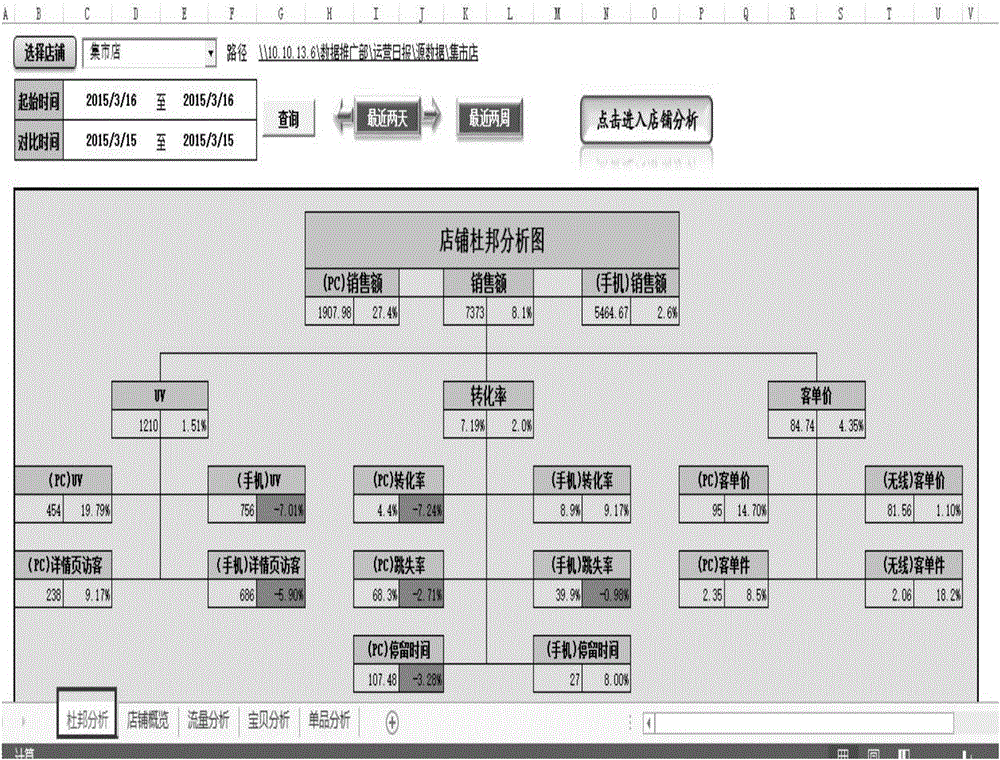

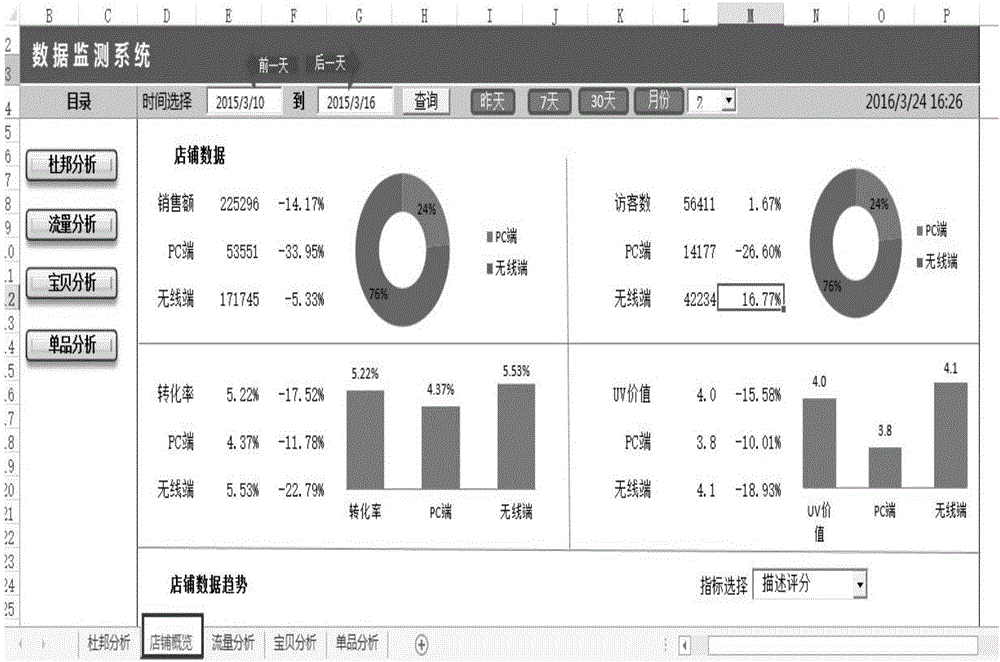

Data control method, data control terminal, data control platform and system

InactiveCN106127394AImprove experienceReasonable analysisBuying/selling/leasing transactionsResourcesMonitoring dataReal-time computing

The invention provides a data control method, a data control terminal and a data control system. The method comprises the following steps that a monitoring terminal obtains the monitoring data corresponding to a monitored object; the monitoring terminal receives an analysis request sent by the monitored object, selects a corresponding analysis strategy according to the feature information of the monitored object, and carries out the processing of the analysis request. The method achieves the multi-dimensional and differentiated management of online shops, and greatly improves the experience of online shopping.

Owner:GUANGZHOU RUOYUCHEN TECH CO LTD

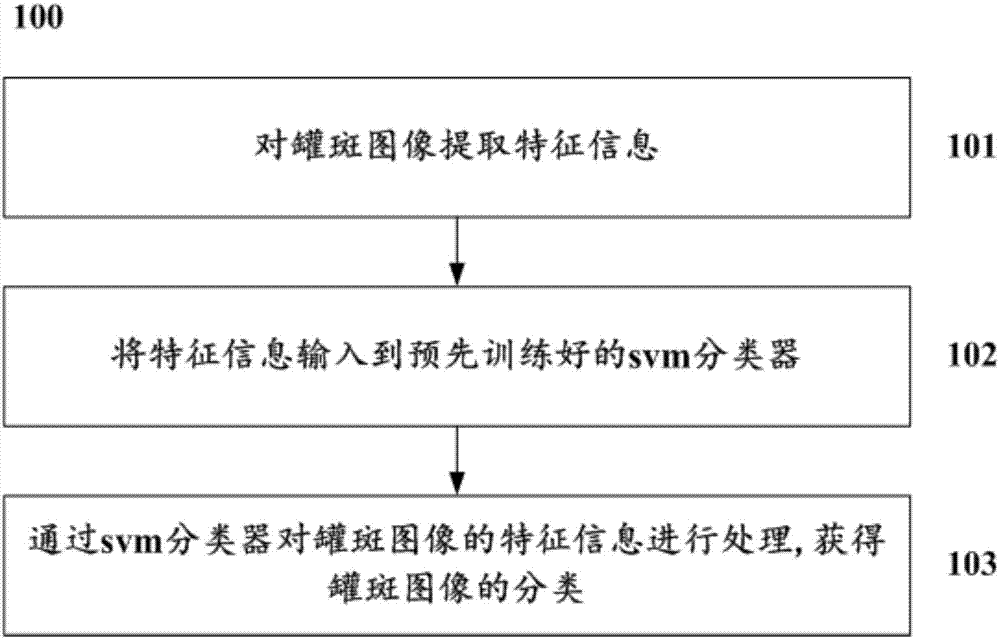

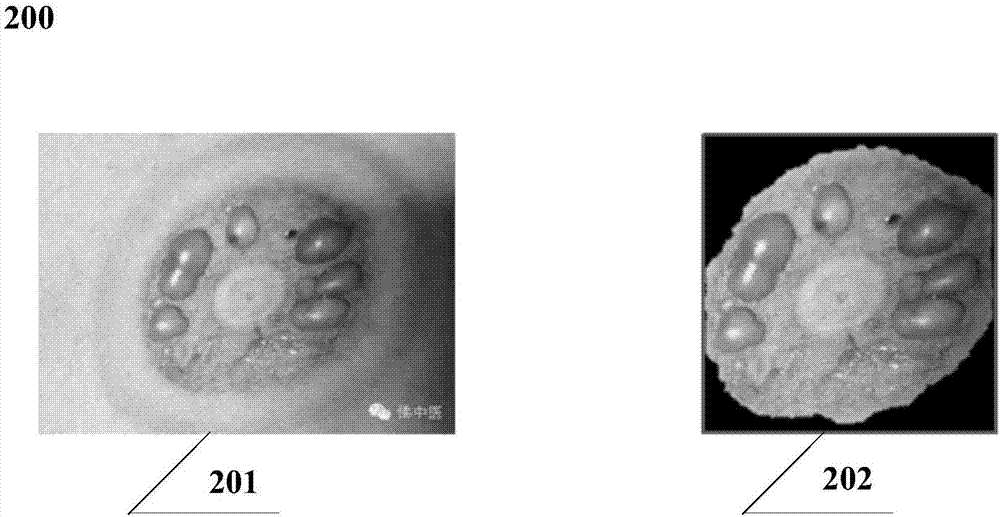

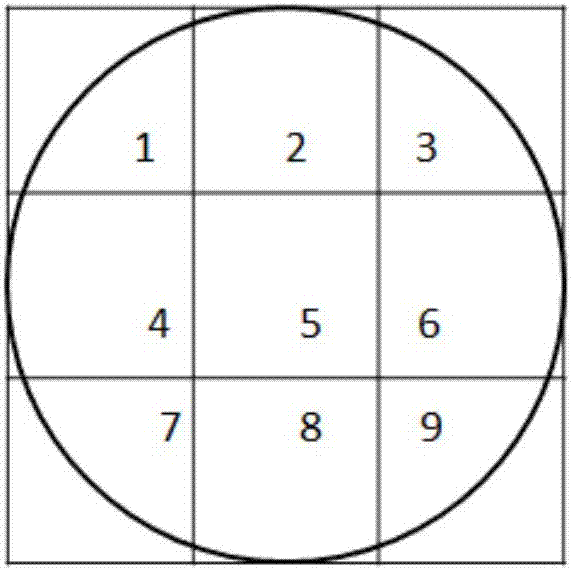

Method and system used for processing cupping patch image feature

ActiveCN107292894AScientific analysisObjective analysisImage enhancementImage analysisPattern recognitionSvm classifier

The invention discloses a method used for processing the cupping patch image feature. The method comprises extracting feature information from a cupping patch image, inputting the feature information into an SVM classifier which is trained in advance, processing the feature information of the cupping patch image by means of the SVM classifier, and obtaining classification of the cupping patch image. The feature information comprises the percentage and position information of feature colors in the cupping patch image, and the feature region type and the position information of the feature region. According to the technical scheme, the user only needs to hold a mobile terminal in hand to take a photo to achieve analysis of the cupping patch image, an accurate analysis result can be obtained, and theorization and scientification of cupping patch analysis can be achieved.

Owner:OVATION HEALTH SCI & TECH CO LTD

Intelligent wearing device for archery

InactiveCN106362383AImprove the accuracy of judgmentJudgment accuracySport apparatusElectricityHeart rate change

The invention relates to an intelligent wearing device for archery. The intelligent wearing device comprises a pressure sensor, a first six-axis sensor, a heart rate sensor, an electroencephalogram sensor, a cutaneogalvanic reaction sensor, a plurality of second six-axis and geomagnetic sensors, wherein the pressure sensor, the first six-axis sensor and the heart rate sensor are used for judging whether an archery process is finished genuinely and reflecting heart rate changes and cardiopulmonary function changes in the archery process; the electroencephalogram sensor and the cutaneogalvanic reaction sensor are used for determining attention concentration degree, mental relaxation degree and mental tension degree in the archery process; the second six-axis and geomagnetic sensors are used for capturing dynamic tracks of exercise motions and forming a track of digital 3D restoration of archery motions, so as to play back differences of the archery motion performed each time, make a comparison on consistency of the archery motion performed each time and determine archery motion accuracy. By adopting the various sensors to detect archery motion signals and human brain current signals and the like, athletes' archery motions are analyzed, misjudgment caused by human factors is avoided, and a judging result is accurate.

Owner:杨开源

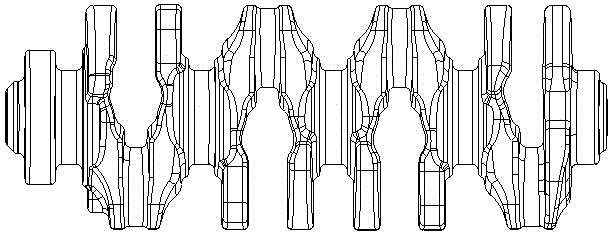

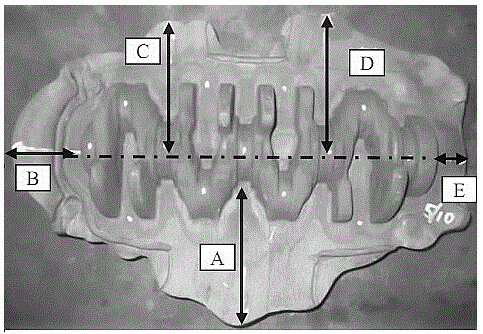

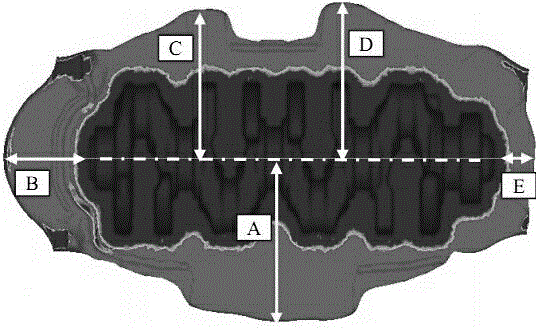

Method for conducting analog simulation on crank die forging process through computer aided engineering (CAE)

InactiveCN104636557AStrong representativePracticalSpecial data processing applicationsComputer-aidedEngineering

The invention belongs to the technical field of metal plastic forming processes, and provides a method for conducting analog simulation on the crank die forging process through computer aided engineering (CAE). The method includes the steps of extracting the parting surface chamfer of a pre-forging die chamber, the length ratio factor of the pre-forging die chamber and a final-forging die chamber, the width ratio factor of the pre-forging die chamber and a final-forging die chamber and the height ratio factor of the pre-forging die chamber and a final-forging die chamber through orthogonal experiments, and establishing a factor level table; forging a CAE sample and an actual crank by drawing a crank model through CAD; conducting final-forging load testing, wherein the maximum forming load of the pre-forging die chamber is achieved when the partial surface chamfer is 8, the length ratio is 0.998, the width ratio is 0.98 and the height ratio is 1.12, and the maximum final forging forming load is achieved when the partial surface chamfer is 8, the length ratio is 0.998, the width ratio is 0.95 and the height ratio is 1.09. The finite element principle analysis method which has quite high representativeness, practicability and scientificity has the advantages that workloads are reduced, implementation is easy, the optimal conclusion is obtained, the forming load is greatly reduced, the forming defects are eliminated, and the die service life is prolonged.

Owner:SHANGHAI AIYI INFORMATION TECH

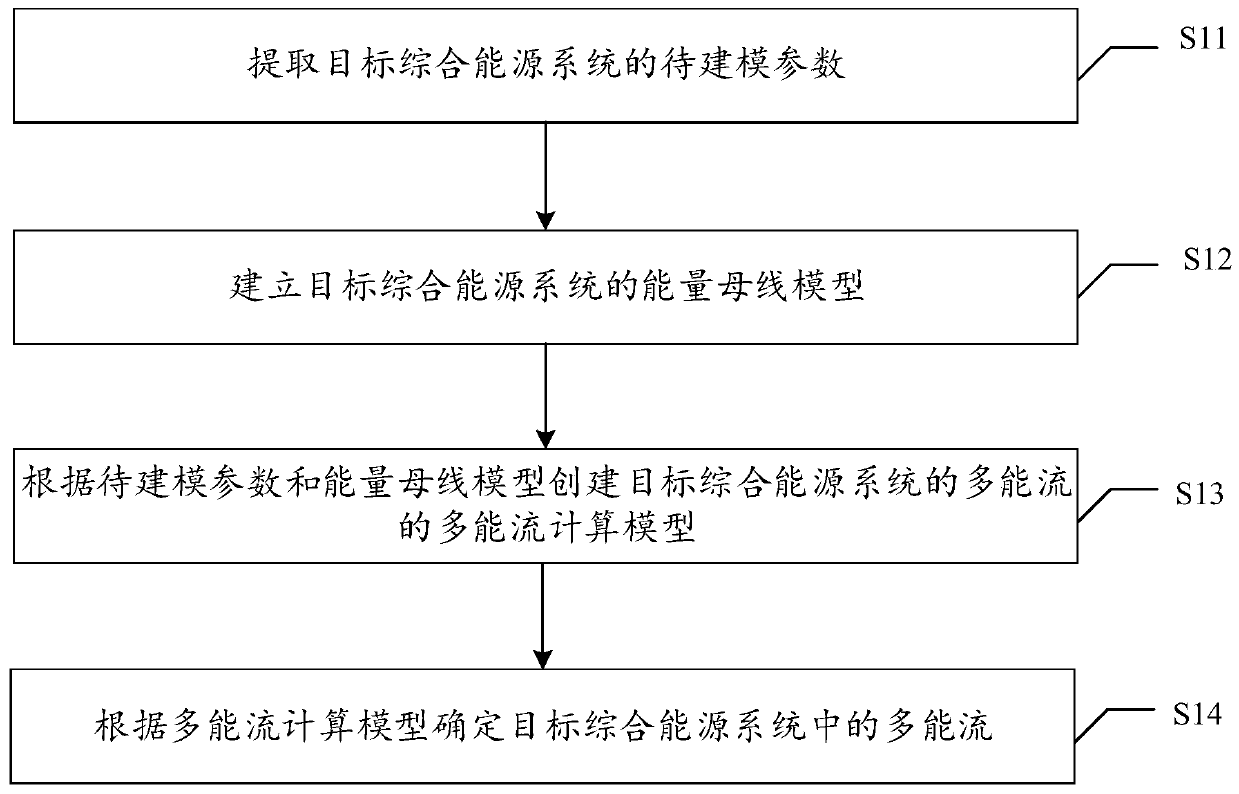

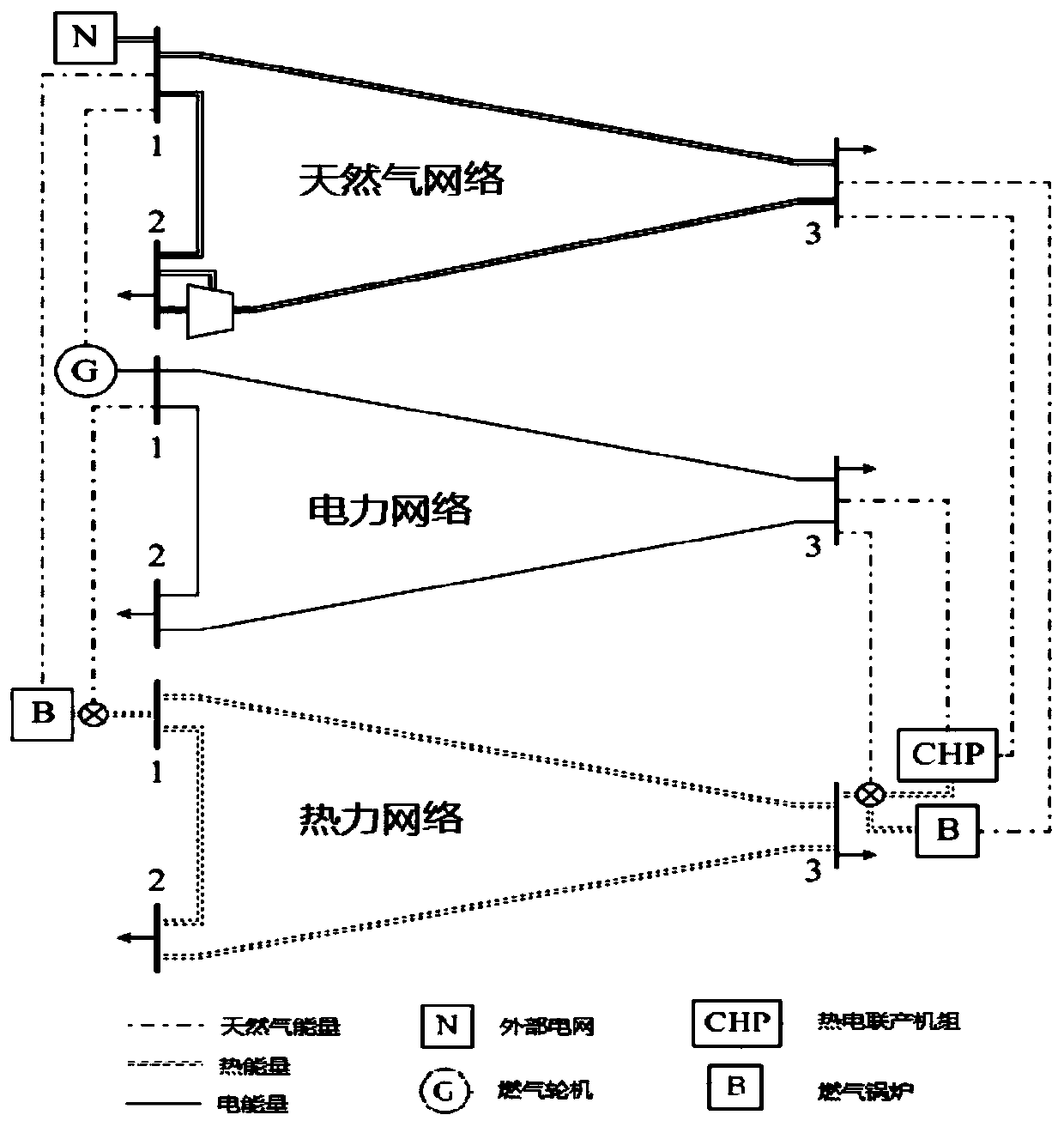

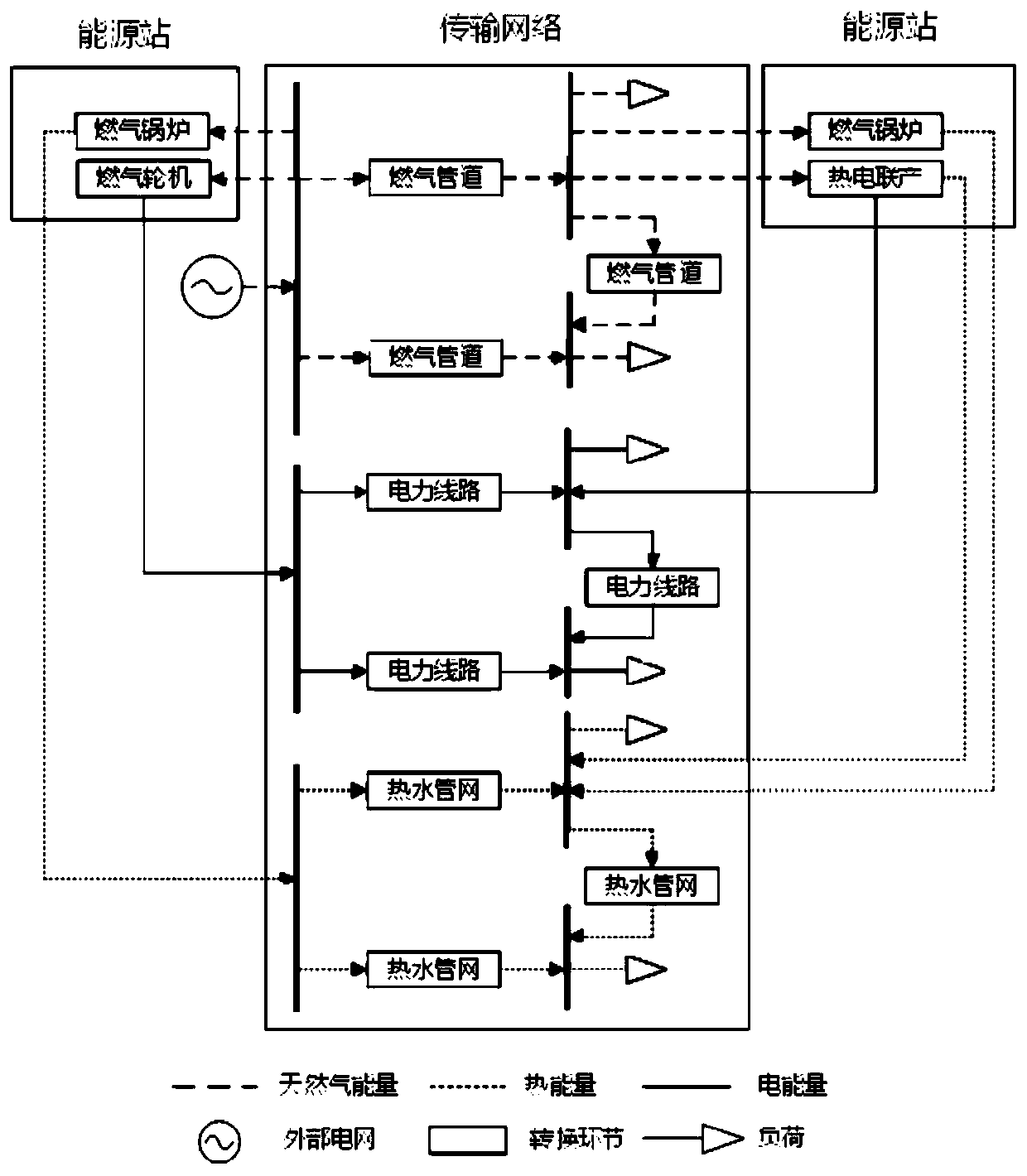

Multi-energy flow simultaneous calculation method of comprehensive energy system based on universal energy bus

ActiveCN109977595AScientific analysisAccurate analysisData processing applicationsDesign optimisation/simulationModel parametersEngineering

The invention discloses a multi-energy flow simultaneous calculation method of a comprehensive energy system based on a universal energy bus. The method comprises the steps of extracting the to-be-modeled parameters of a target comprehensive energy system; establishing an energy bus model of the target comprehensive energy system; creating a multi-energy flow calculation model of the multi-energyflow of the target comprehensive energy system according to the to-be-modeled parameters and the energy bus model; and determining the multi-energy flow in the target comprehensive energy system according to the multi-energy flow calculation model. In the prior art, the extensive management is carried out on the target comprehensive energy system; and according to the multi-energy flow calculationmethod for the target comprehensive energy system, after the multi-energy flow of the target comprehensive energy system is obtained through calculation, a worker can analyze the target comprehensiveenergy system more scientifically and accurately, and therefore the safety and the reliability in the analysis process of the target comprehensive energy system are guaranteed.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

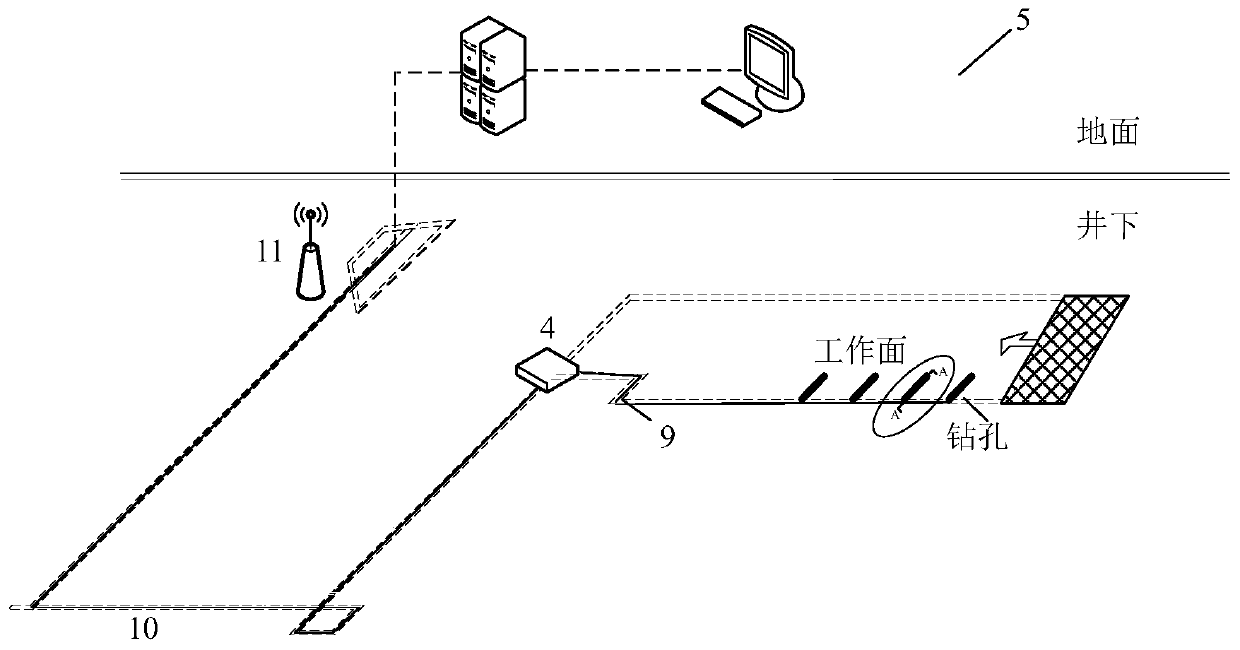

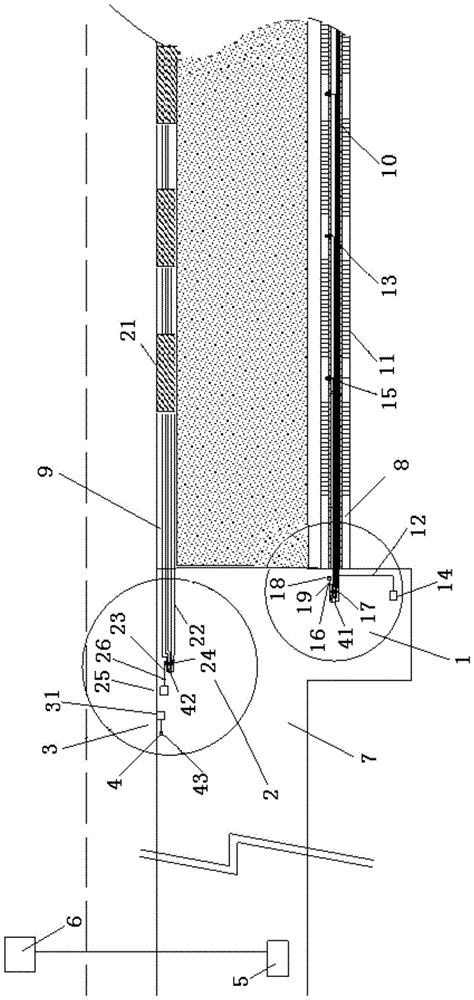

Multi-parameter monitoring device and method for rock burst in coal mine main roadway area

InactiveCN110925020AAccurate analysisScientific analysisSurveyMining devicesCable transmissionMining engineering

The invention discloses a multi-parameter monitoring device and method for rock burst in a coal mine main roadway area. The device comprises a drilling stress monitoring device, a drilling deformationmonitoring device, a plurality of monitoring substations, a monitoring master station and a ground terminal. One end of the drilling stress monitoring device is arranged in a stress monitoring drilling hole of one side of the roadway, the other end of the drilling stress monitoring device is fixed at the side part of the roadway, and the two ends of the drilling stress monitoring device are connected through a liquid guide pipe. One end of the drilling deformation monitoring device is arranged in a deformation monitoring drilling hole of one side of the roadway, the other end of the drillingdeformation monitoring device is fixed at the side part of the roadway, and the two ends of the drilling deformation monitoring device are connected through a liquid guide pipe. The drilling stress and deformation monitoring devices monitor drilling stress and deformation signals in real time and transmit the signals to the nearby monitoring substations through a communication cable; each monitoring substation transmits monitoring signals to the monitoring master station through optical fibers, and the monitoring master station transmits all monitoring signals to the ground terminal through aring network. The device has the characteristics of flexibility, reliability, good monitoring effect, low cost and the like, and can be widely applied to prediction and early warning of rock burst inthe coal mine main roadway area.

Owner:NORTH CHINA INST OF SCI & TECH

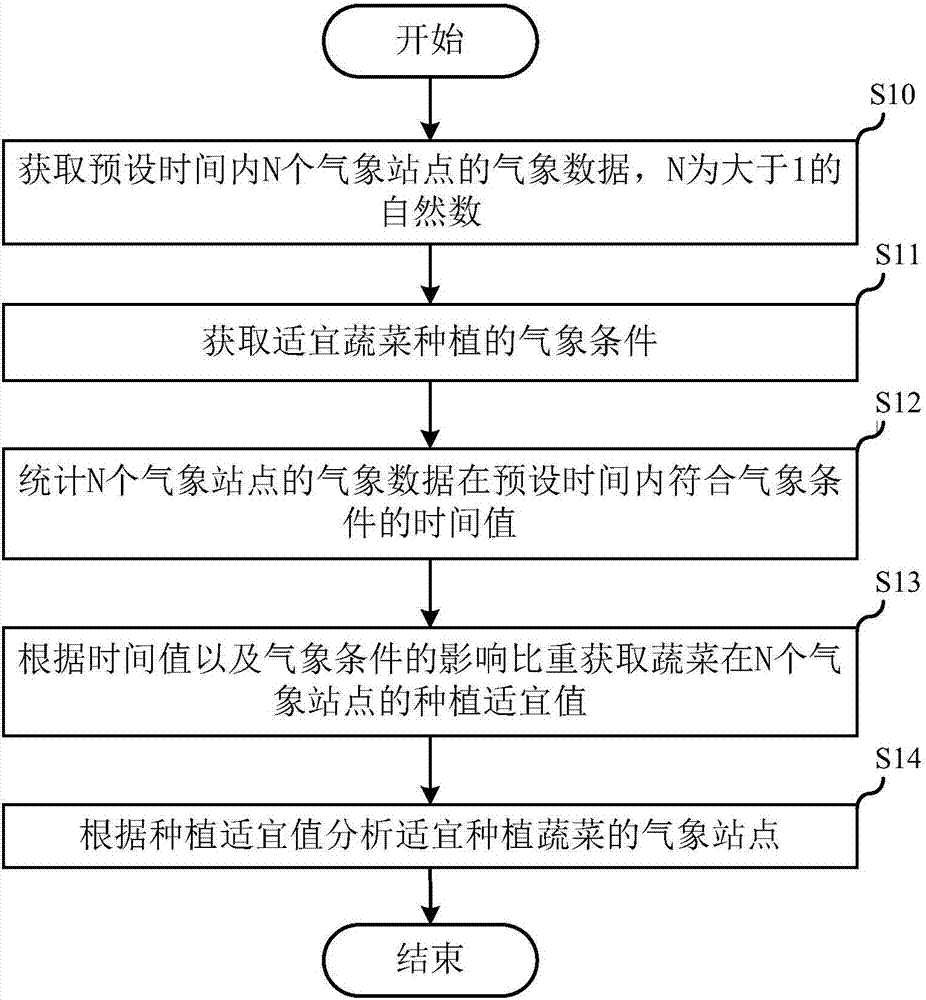

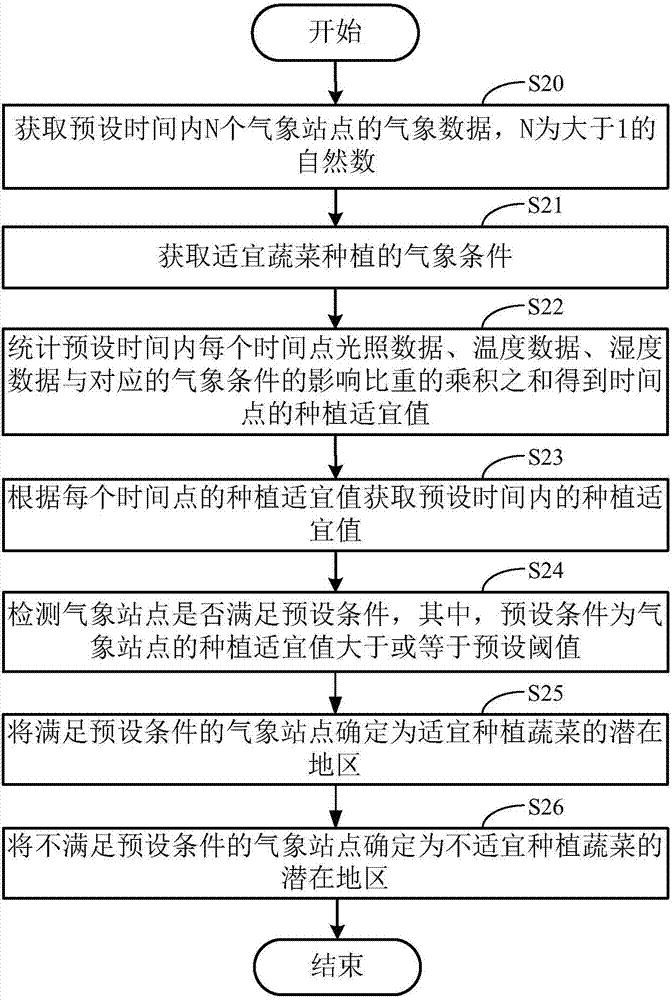

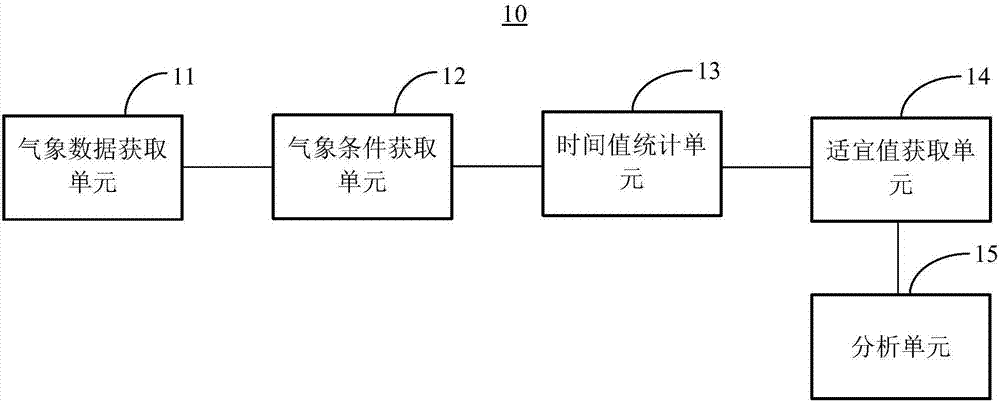

Analysis method and device based on vegetable cultivated fields

InactiveCN107464190AScientific analysisEasy to analyzeData processing applicationsAnalysis methodComputer science

The embodiment of the present invention relates to the technical field of the Internet of Things, and discloses an analysis method based on vegetable planting sites. In the present invention, the analysis method based on the vegetable planting place includes: obtaining meteorological data of N meteorological stations within a preset time, where N is a natural number greater than 1; obtaining meteorological conditions suitable for vegetable planting; counting the meteorological data of N meteorological stations The time value of the data meeting the meteorological conditions within the preset time; according to the time value and the influence ratio of meteorological conditions, the suitable value of vegetable planting at N meteorological stations is obtained; according to the suitable value of planting, the meteorological stations suitable for planting vegetables are analyzed. The vegetable planting site-based analysis method and device provided by the invention can scientifically analyze potential vegetable planting sites.

Owner:SHENZHEN SPRINGWOODS HLDG CO LTD

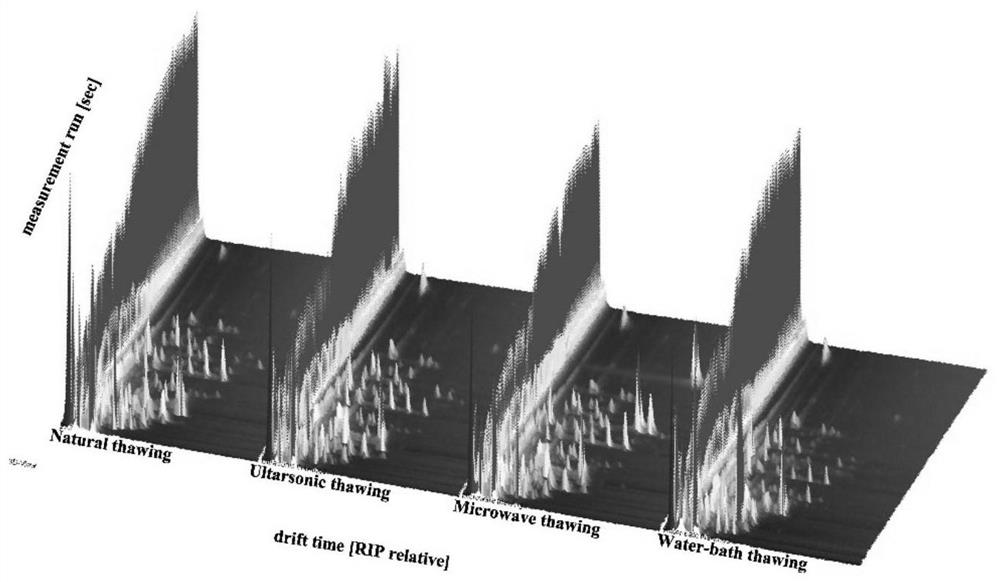

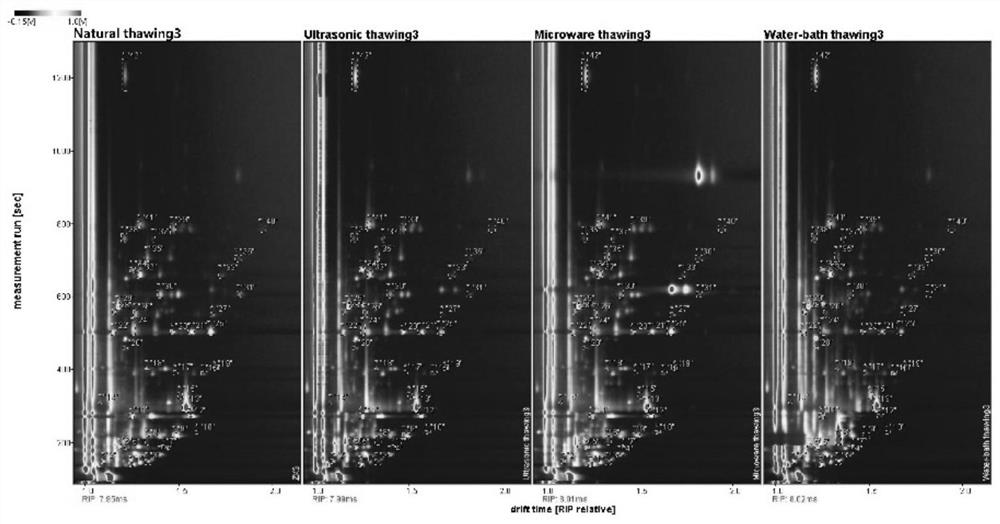

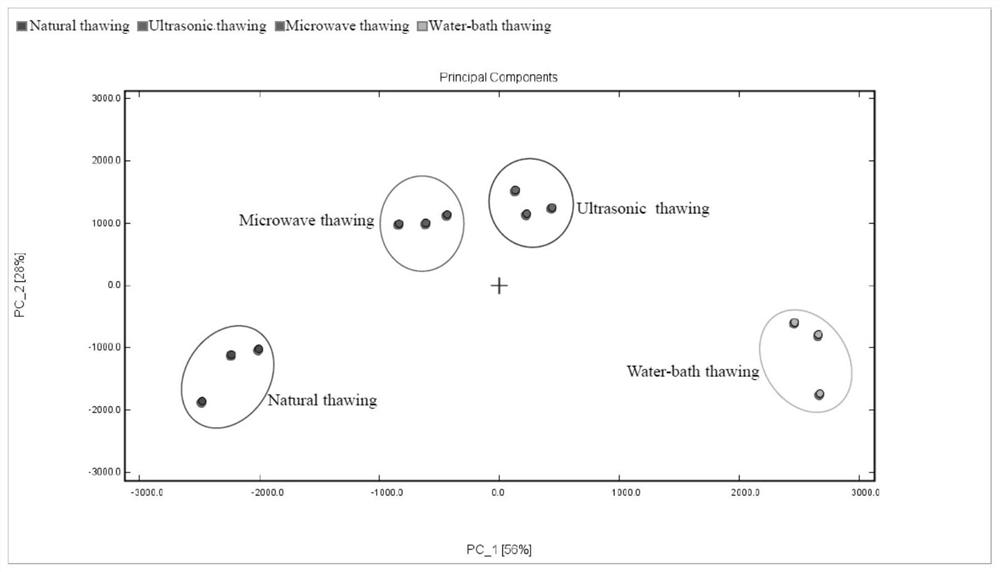

Fotiaoqiang unfreezing method and quality analysis method of unfrozen Fotiaoqiang

PendingCN113804786AQuality impactEasy to analyzeComponent separationMaterial analysis by electric/magnetic meansBiotechnologyBiochemical engineering

The invention relates to the technical field of food, and particularly relates to an unfreezing method for improving flavor quality of frozen Fotiaoqiang and a quality analysis method of unfrozen Fotiaoqiang. The unfreezing method comprises the following steps: putting the frozen Fotiaoqiang in an ultrasonic device, and unfreezing in still water till that the center temperature is 25 DEG C. The analysis method comprises the following step: determining the influence of differentunfreezing modes on the quality of Fotiaoqiang according to the aldehydes substance change of the unfrozen Fotiaoqiang sample. According to the Fotiaoqiang unfreezing method disclosed by the invention, as only a low-frequency ultrasonic method is adopted to assist still water unfreezing, the technical prejudice that the Fotiaoqiang wall needs to be unfrozen by combining microwave, natural unfreezing and other modes in the art in the field is overcome. According to the analysis method for the quality of the unfrozen Fotiaoqiang, the influence of different unfreezing modes on the quality of the Fotiaoqiang product can be scientifically and comprehensively obtained only by measuring the change of the aldehyde flavor substances of the unfrozen Fotiaoqiang sample.

Owner:FUJIAN AGRI & FORESTRY UNIV

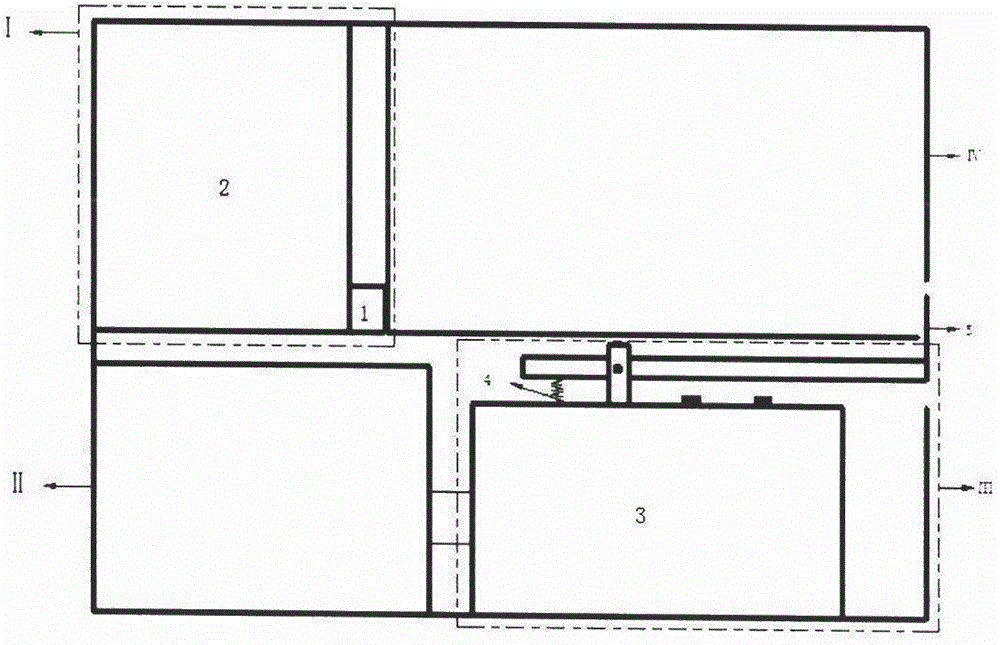

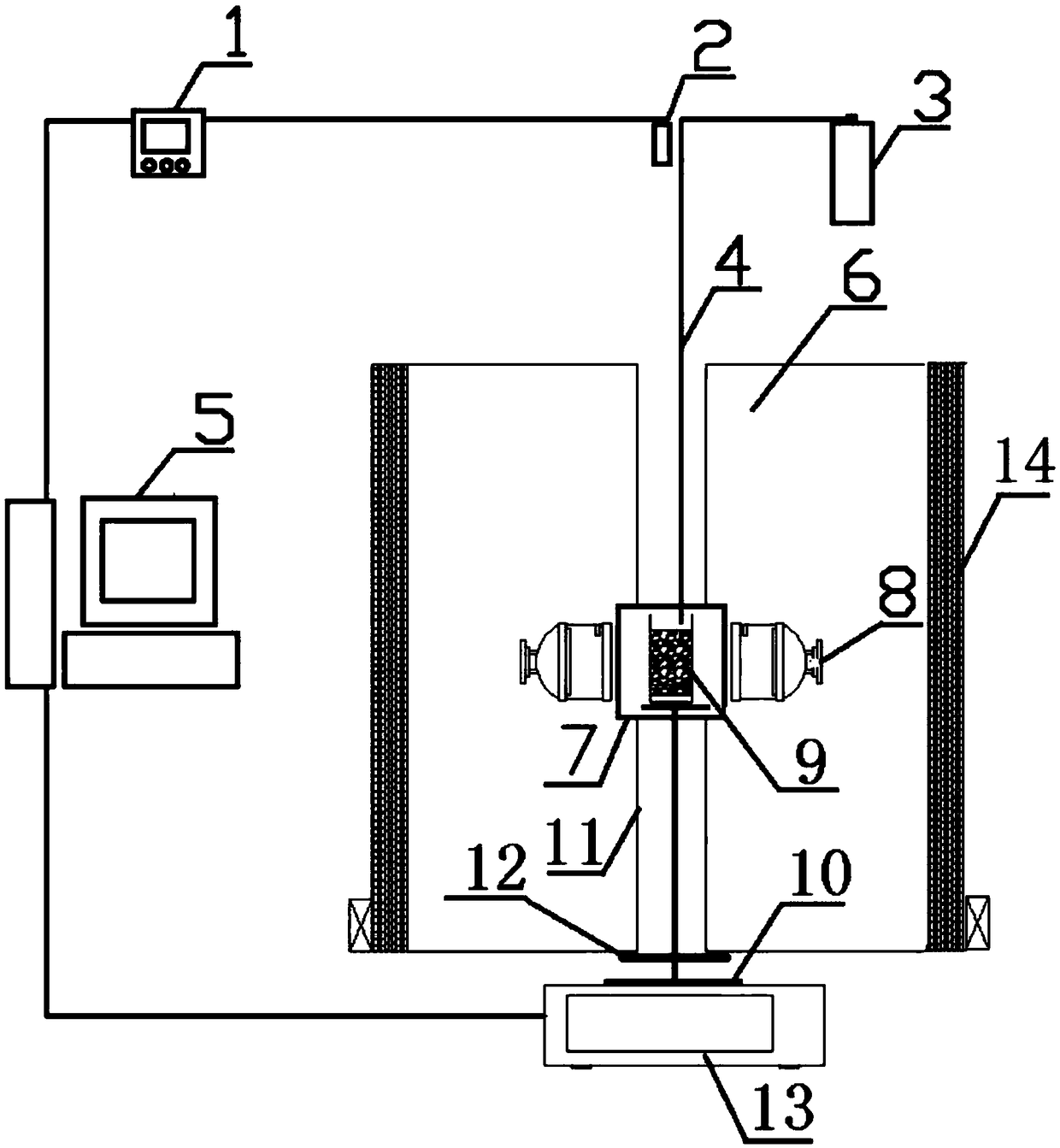

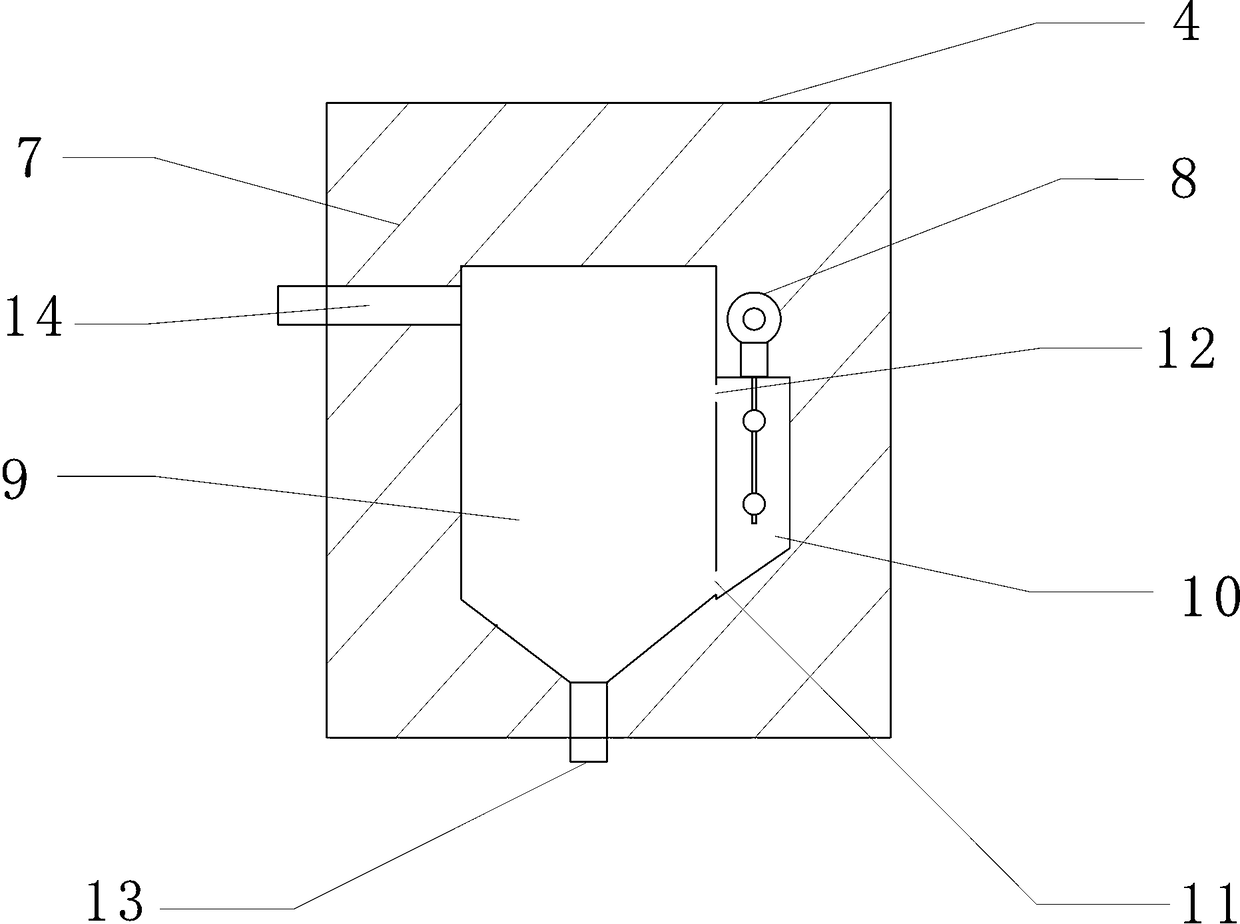

Thermogravimetric analysis device and method for microwave pyrolysis sludge

PendingCN108445041AReduce the impactReduce distractionsRadiation pyrometryMaterial heat developmentMicrowave ovenMicrowave pyrolysis

The invention relates to a thermogravimetric analysis device and method for microwave pyrolysis sludge. The device is characterized in that microwave magnetrons are arranged on two sides of a microwave oven cavity; an infrared temperature measuring probe is arranged directly above a quartz beaker, and an infrared temperature measuring instrument is connected with a computer; nitrogen in a nitrogenbottle is supplied by a quartz fine tube to the quartz beaker located in the microwave oven cavity; the upper end of a quartz bracket supported on an online weighing balance extends into a bracket channel and supports the quartz beaker; the online weighing balance is connected with the computer; the quartz bracket is sleeved with a metal shielding ring. The method comprises the followings steps:a sludge sample is put in the quartz beaker in the microwave oven cavity; nitrogen is supplied to the quartz beaker by the quartz fine tube; the microwave oven cavity is heated by the microwave magnetrons; temperature and quality data are obtained by the computer in real time. The device can prevent microwave leakage, improve measurement accuracy of the sample temperature, prevent adverse effectson the heated sample, and improve measurement accuracy of the sample temperature. Mass and temperature of the sample can be accurately measured and collected in real time with the method.

Owner:XUZHOU UNIV OF TECH

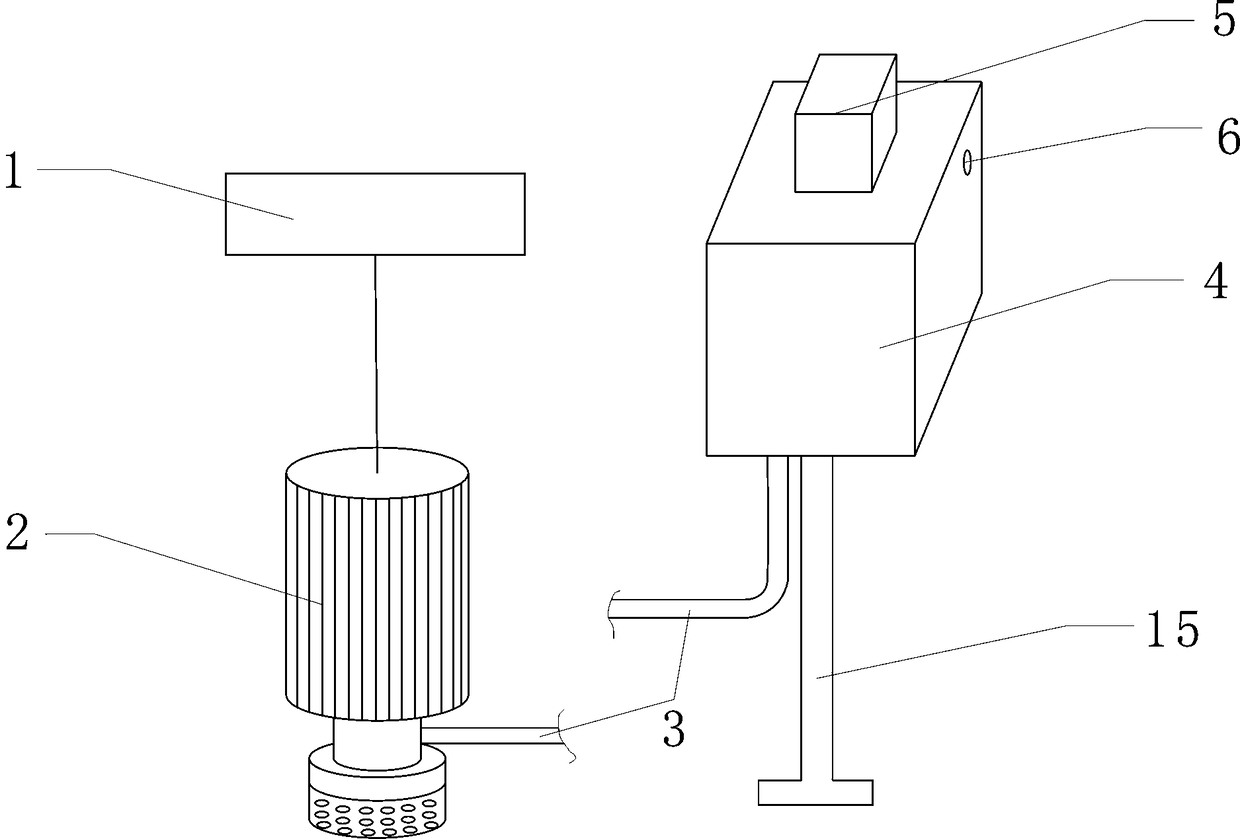

Online measuring device for suspended sediment

PendingCN108469257AHigh degree of automationScientific collectionTransmission systemsOpen water surveyMeasurement deviceWater storage tank

The invention provides an online measuring device for suspended sediment. The online measuring device comprises a submerged pump and a heat insulated box, wherein a water storage tank is arranged in the heat insulated box, and a first inlet is formed in the bottom of the water storage tank and connected with the submerged pump through a connecting pipe; a second outlet and an auxiliary water tankare arranged on the side surfaces of the heat storage tank, a second inlet is formed in the lower part of the auxiliary water tank and communicated with the water storage tank, and a second outlet isformed in the upper part and communicated with the water storage tank; an online cement paste density measuring instrument is arranged in the auxiliary water tank, and a control box is arranged at thetop of the heat insulated box. The online cement paste density measuring instrument and modern technologies such as data acquisition, modern communication, computer network, database and informationanalysis are closely combined with test requirements of hydrologic suspended sediment, the efficient and reliable hydrologic suspended sediment measuring and forecasting equipment with high automationdegree is formed, automatic collection, networking transmission and scientific analysis of suspended sediment information are realized, and timeliness and reliability of collection, transmission, processing and analysis of the suspended sediment information are effectively improved.

Owner:邢杰炜

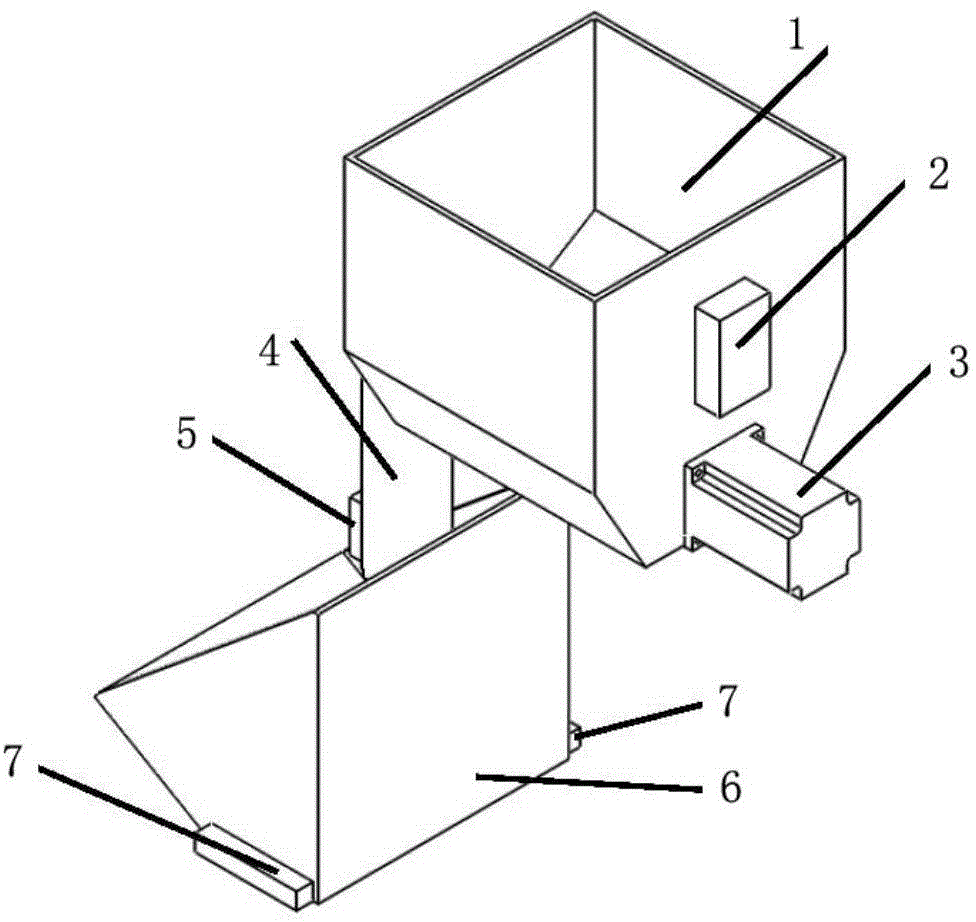

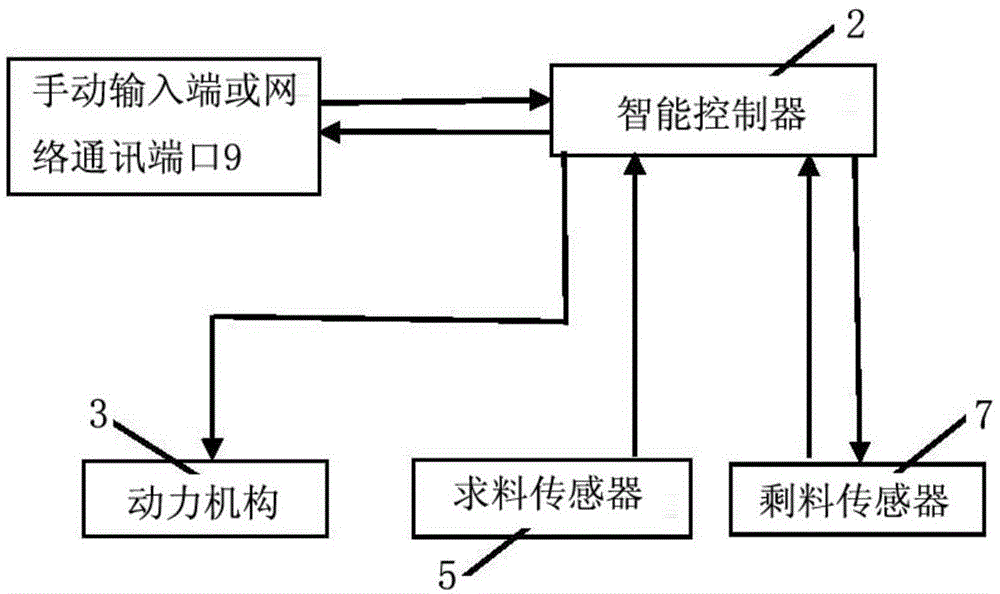

Intelligent on-demand feeding device

InactiveCN104570904APrevent diseaseScientific analysisProgramme control in sequence/logic controllersControl signalEconomic benefits

The invention relates to an intelligent on-demand feeding device. The feeding device comprises a feeding mechanism and an intelligent control structure. The feeding mechanism is characterized by comprising a material storing box, a breeding tank, a material conveying pipe, a transmission mechanism and a power mechanism, and the intelligent control structure comprises a material demanding sensor, residual feed sensors and an intelligent controller; a feed opening of the conveying pipe is fixed in the bottom of the material storing box and is communicated with the material storing box, and a discharge opening of the material conveying pipe is communicated with the breeding tank; a movable power input end of the transmission mechanism is connected with a power output end of the power mechanism; a control end of the power mechanism is connected with one of control signal output ends of the intelligent controller; a signal output end of the material demanding sensor is connected with one of signal input ends of the intelligent controller; the signal output ends of the residual feed sensors are connected with two of the signal input ends of the intelligent controller; a control signal input port of the intelligent controller is connected with a manual input end or a network communication port; an intelligent residual feed detecting structure consists of the intelligent controller and the residual feed sensors. Through the use of the feeding device disclosed by the invention, diseases caused by the deterioration of the residual feed can be avoided, so that the economic benefits can be greatly improved.

Owner:李乔

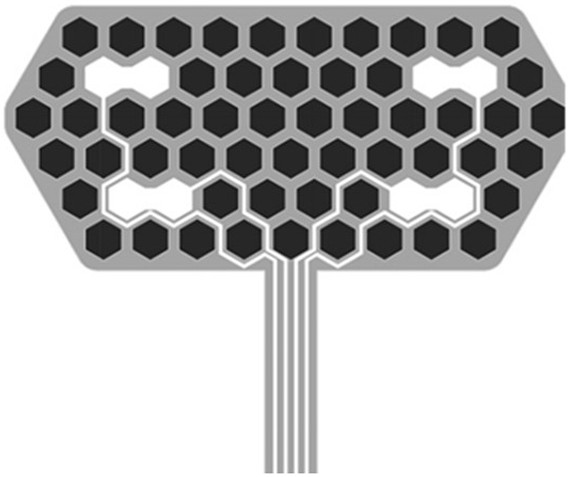

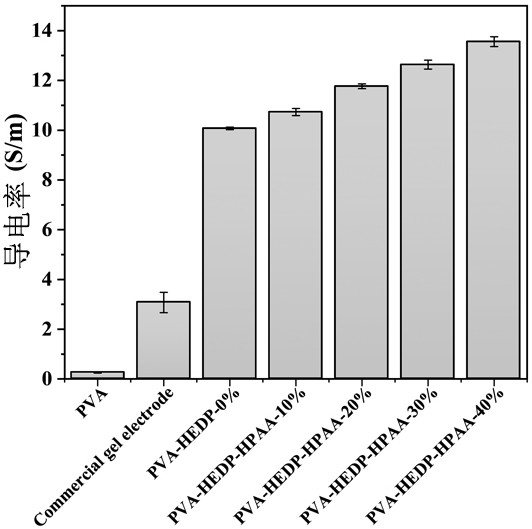

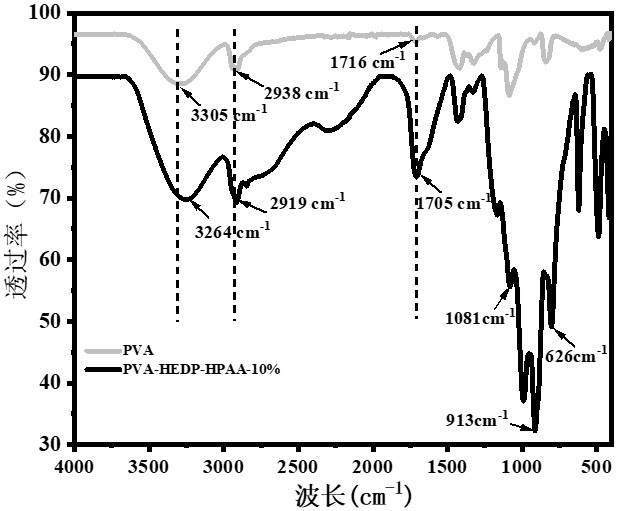

Preparation method of honeycomb electrode patch, honeycomb electrode patch and application

ActiveCN114569135ABreathableFlexible and wearableVacuum evaporation coatingSputtering coatingInterface impedanceInterfacial impedance

The invention relates to a preparation method of a honeycomb electrode patch, the honeycomb electrode patch and application. The preparation method comprises the following steps: S1, preparing transparent self-adhesion conductive hydrogel; s2, manufacturing a honeycomb flexible electrode patch; and S3, specifically cutting the self-adhesive conductive hydrogel prepared in the step S1 to obtain hydrogel in a corresponding shape, then adhering the hydrogel to the exposed gold electrode of the honeycomb flexible electrode patch in the step S2, finally covering the electrode patch with a layer of PET protective film, and carrying out packaging treatment to obtain the transparent honeycomb electrode patch with the self-adhesive high-conductivity hydrogel. The invention has the advantages of air permeability, flexibility, wearable performance, low interface impedance, high anti-interference capability and the like. The method is expected to be applied to actual monitoring of electrophysiological signals of athletes and muscle tracking and scientific guidance of athletes in assisted training.

Owner:JINAN UNIVERSITY +1

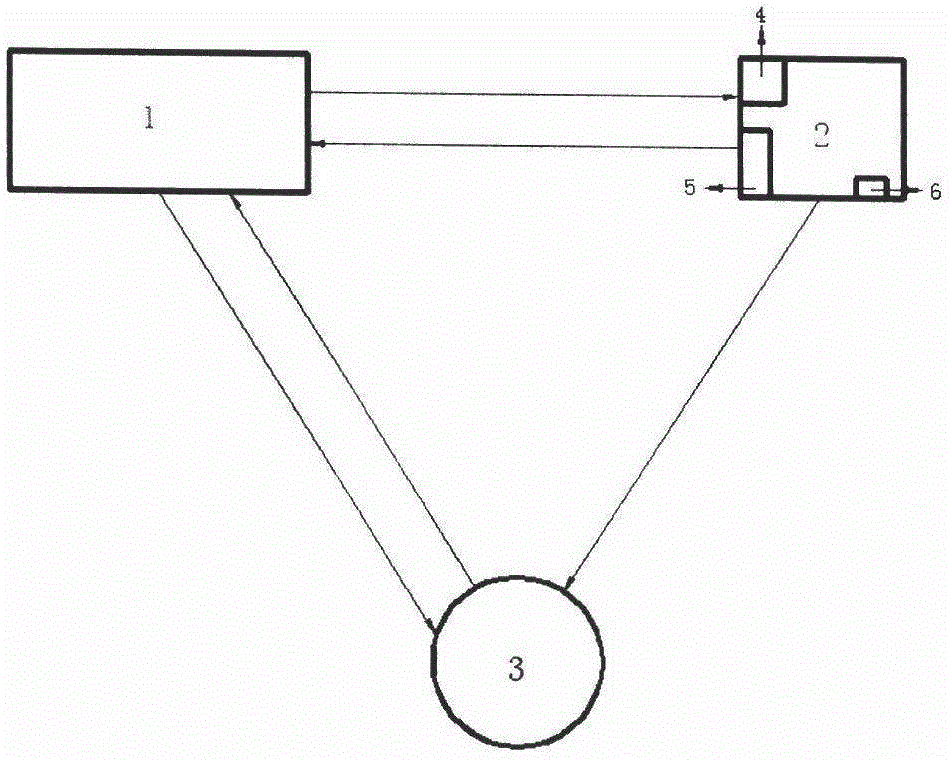

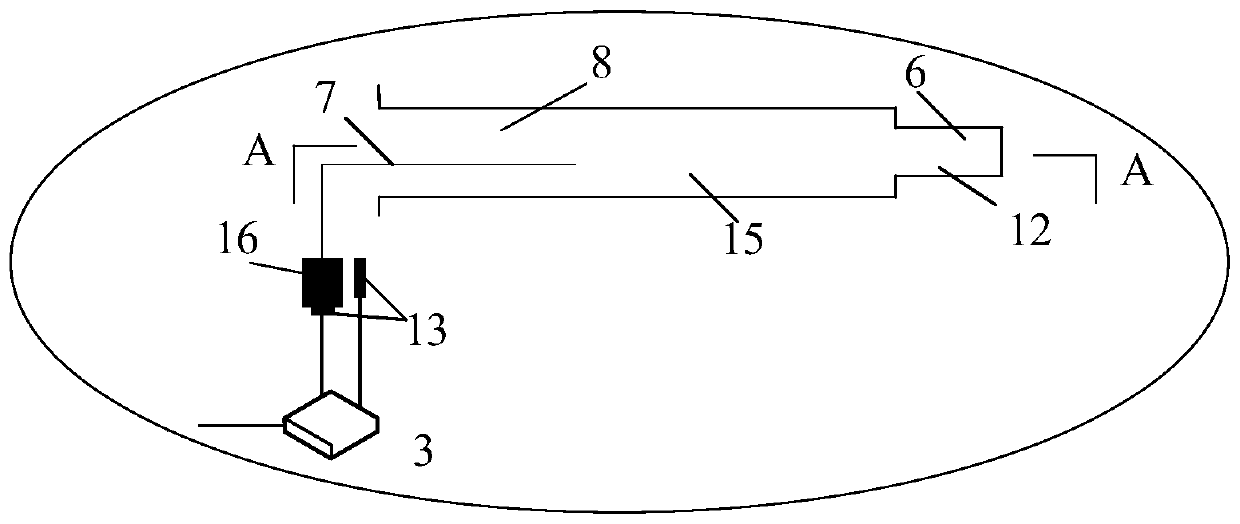

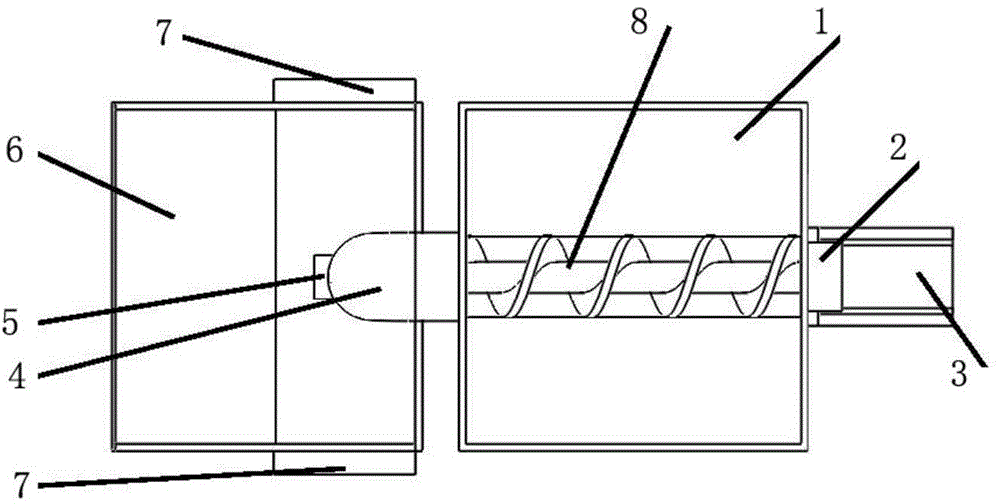

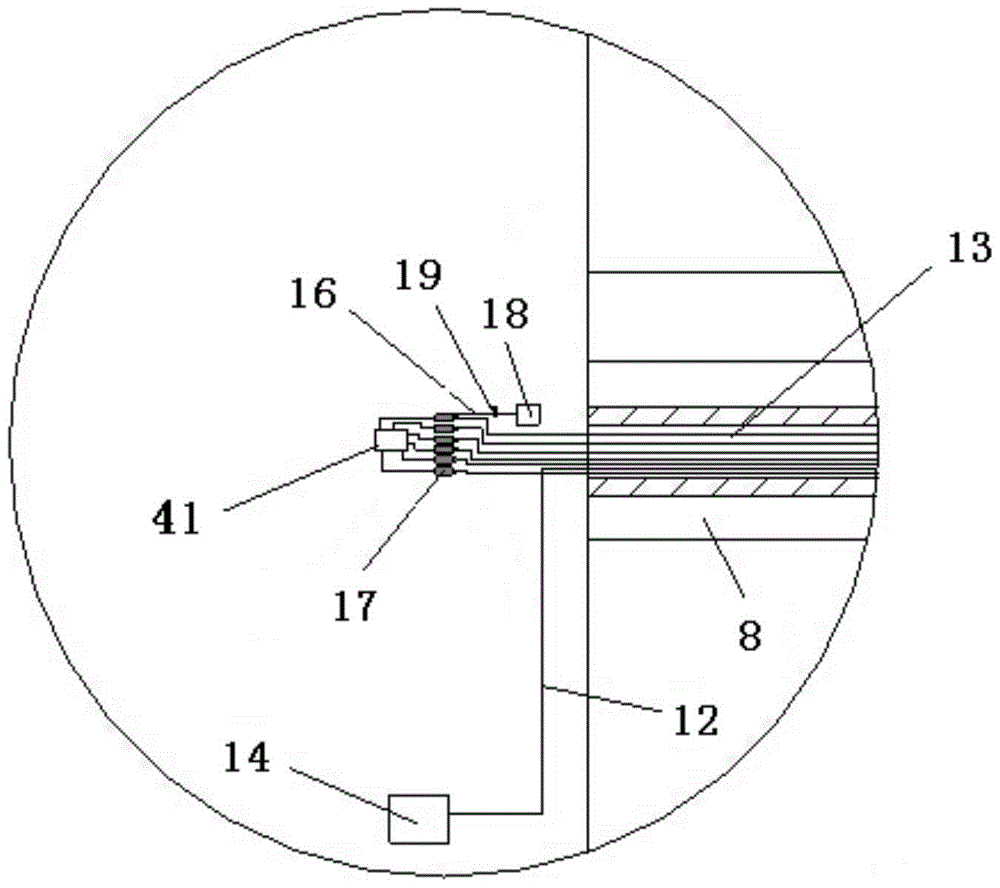

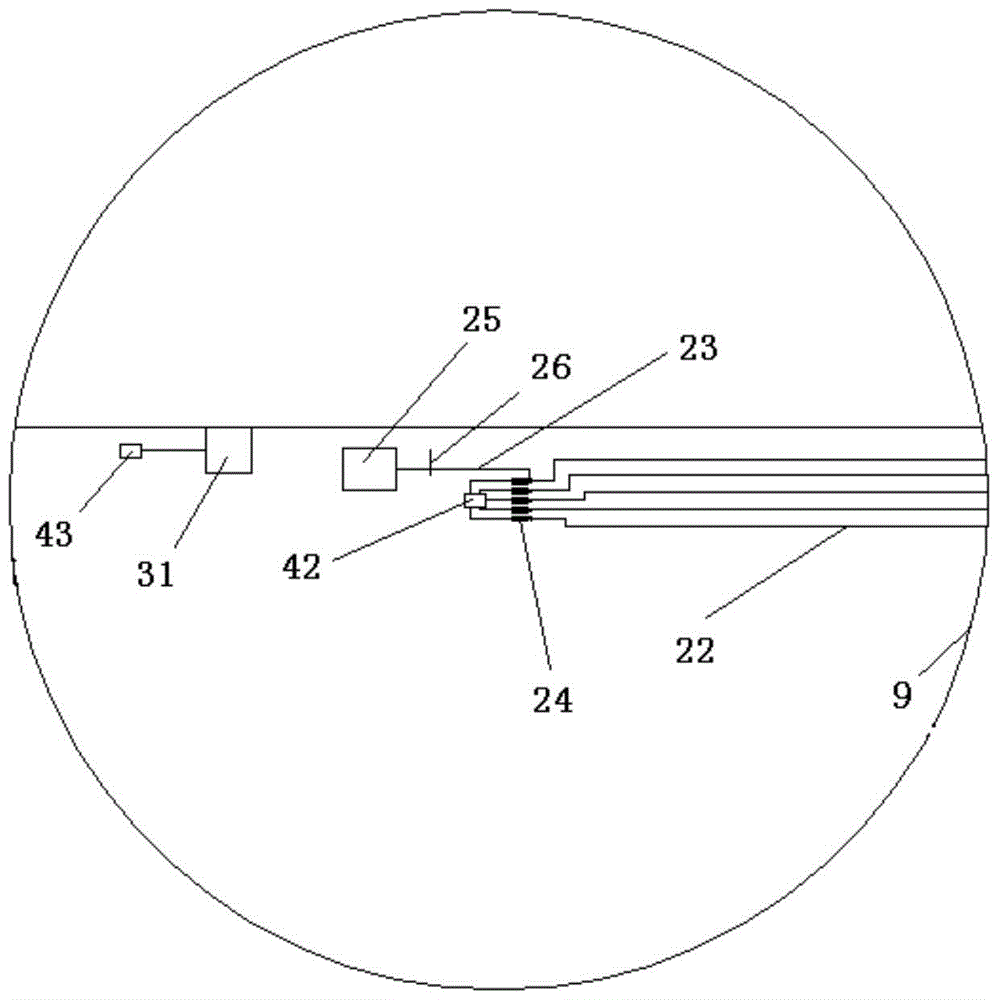

A multi-parameter and multi-measuring point monitoring device for coal mine gas disasters

ActiveCN104500140BRealize real-time dynamic monitoringImprove accuracyMining devicesDevice MonitorCoal mine methane

The invention relates to a coal mine gas disaster multi-parameter and multipoint monitoring device. The device is characterized by comprising a gas pressure monitoring device, a drill hole stress monitoring device, a gas concentration monitoring device, a plurality of monitoring sub stations, a monitoring branch station and a ground terminal. The gas pressure monitoring device is arranged in a first drill hole of one side of a roadway, the drill hole stress monitoring device is arranged in a second drill hole of the other side of the roadway, and the gas concentration monitoring device is suspended on the top plate of the roadway; the gas pressure monitoring device monitors the gas pressure signals in real time and transmits to a first monitoring substation; the drill hole stress monitoring device monitors the drill hole stress signals and transmits to a second monitoring sub station; the gas concentration monitoring device monitors the gas concentration signals of an operation space in real time and transmits to a third monitoring sub station; the first, second and third monitoring sub stations transmit the signals to the monitoring branch substation by the wireless communication technology, and the monitoring branch substation transmits all monitoring signals to the ground terminal through an optical fiber. The device can be widely applied to predication of coal and gas outburst and rockburst of coal mine.

Owner:NORTH CHINA INST OF SCI & TECH

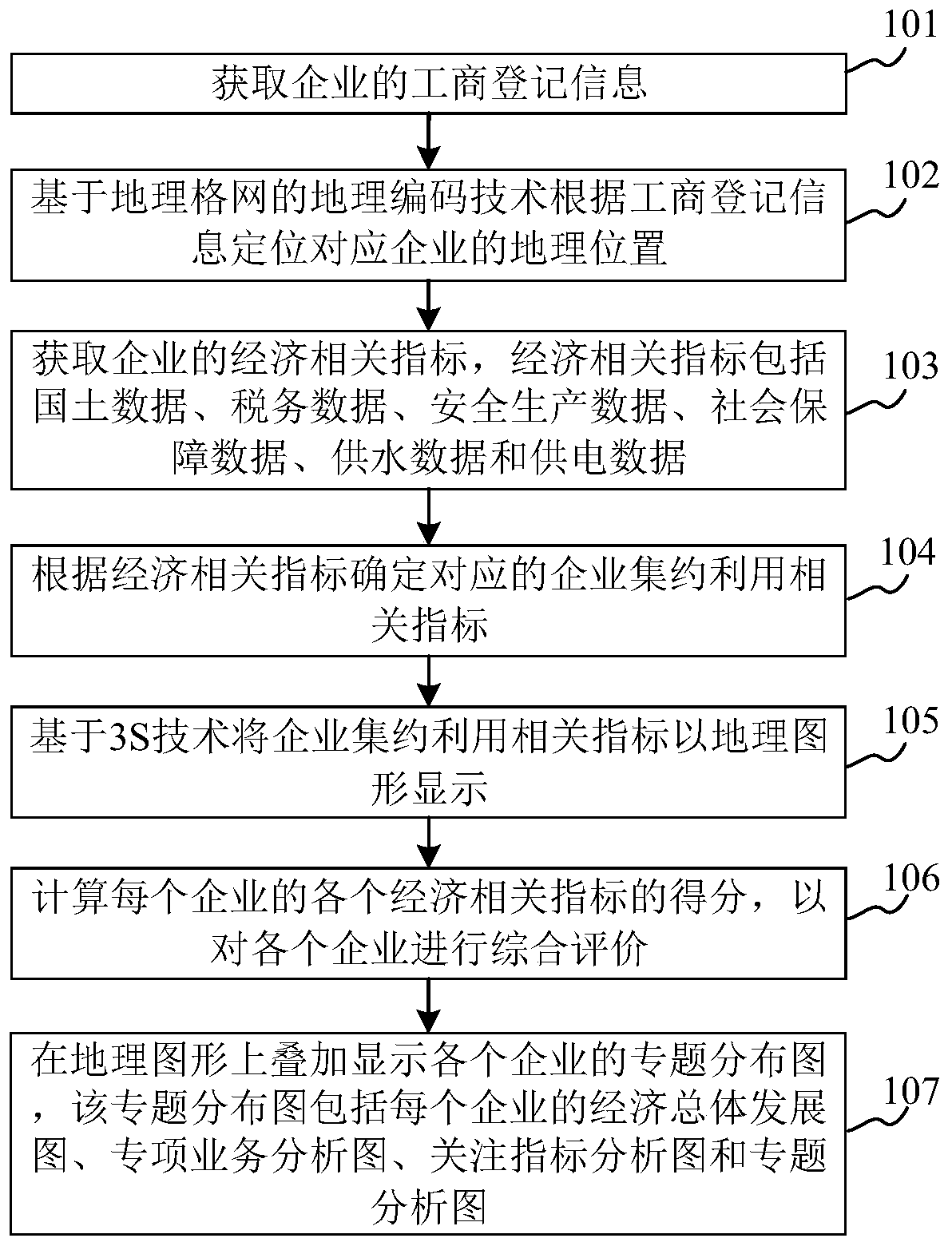

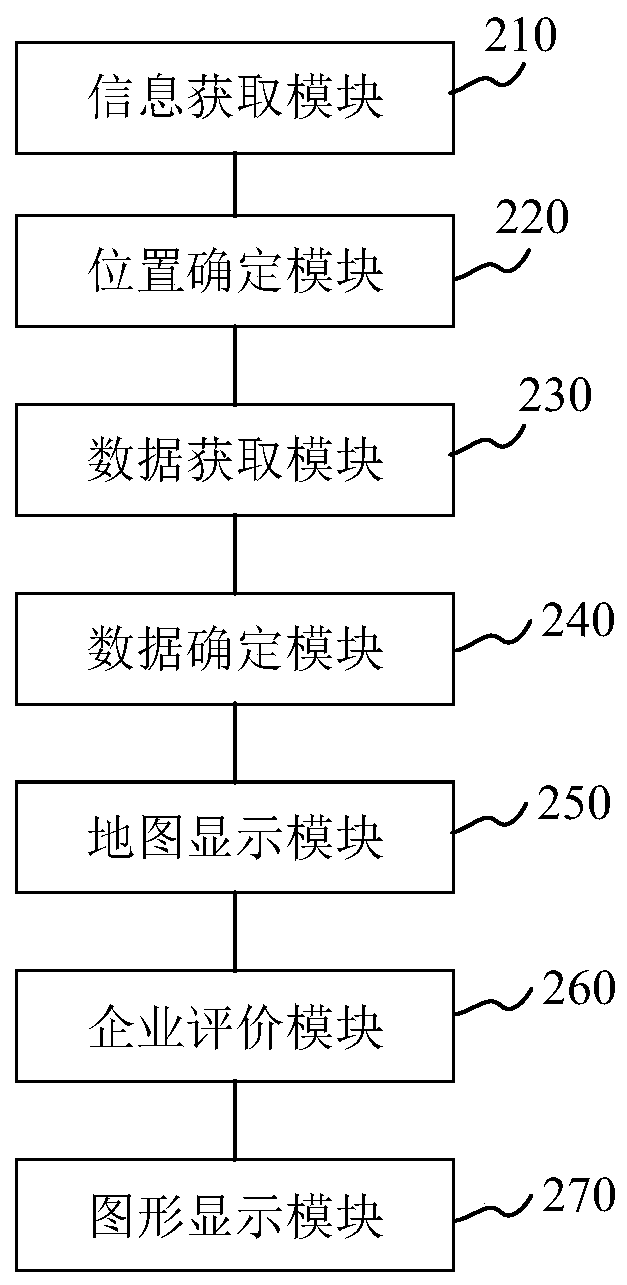

Enterprise resource intensive utilization method and device

PendingCN111598459AImplement data collectionRealize association fusionResourcesGraphicsBusiness enterprise

The invention relates to an enterprise resource intensive utilization method and device, and belongs to the technical field of computers, and the enterprise resource intensive utilization method comprises the steps: obtaining the business registration information of an enterprise; positioning the geographic position of the corresponding enterprise according to the registration information based onthe geocoding technology of the geographic grid; obtaining economic related indexes of the enterprise; determining a corresponding enterprise intensive utilization related index according to the economic related index; displaying enterprise intensive utilization related indexes in a geographic graph based on a 3S technology; and displaying the thematic distribution map of each enterprise on the geographic graph in an overlapping manner, thus solving the problems that in traditional enterprise resource intensive utilization management, data resource accuracy is not high, and enterprises and parcels are lack of association, and analysis and display visualization is not high, and enterprise evaluation model accuracy is not enough. Related index results of economic high-quality development can be comprehensively and integrally associated and displayed, and accurate and scientific analysis and evaluation of economic high-quality development and land and efficiency conditions and the like are achieved.

Owner:苏州云联智慧信息技术应用有限公司

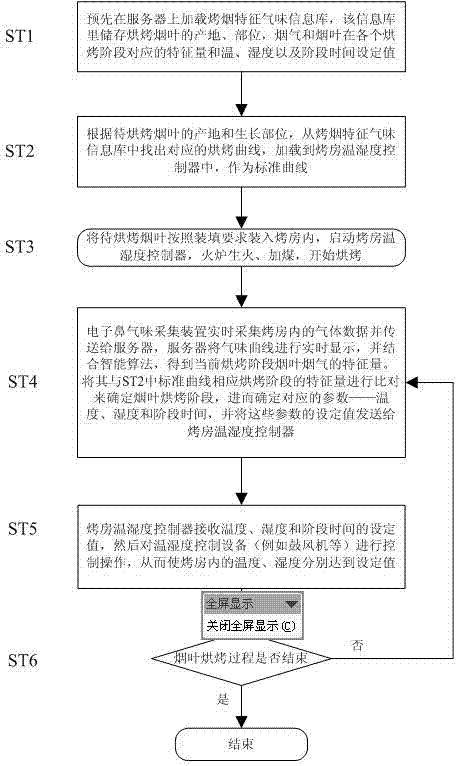

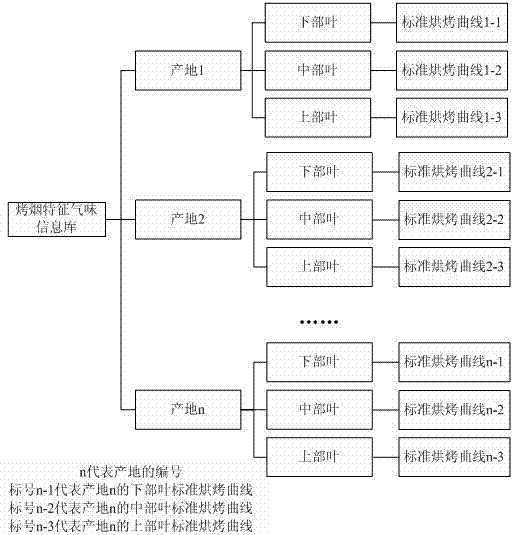

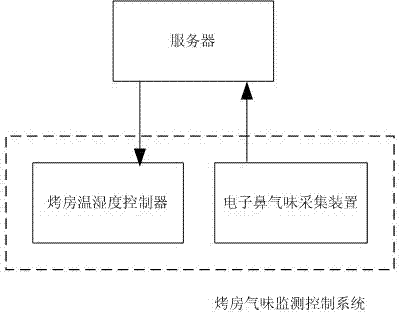

Tobacco leaf curing method based on electronic nose smell monitoring technology

The invention discloses a tobacco leaf curing method based on electronic nose smell monitoring technology. A method for analyzing a flue-cured tobacco smell quickly, conveniently and scientifically is created by applying the electronic nose technology, and regulating and guiding of the whole tobacco curing process with the smell as an index are achieved. The curing technology is reasonably regulated according to characteristics of tobacco of different qualities, so that quality potential of the tobacco is enabled to play to the maximum degree, deserved aroma of the tobacco is cured out, and the flexibility of the curing technology is greatly improved.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +2

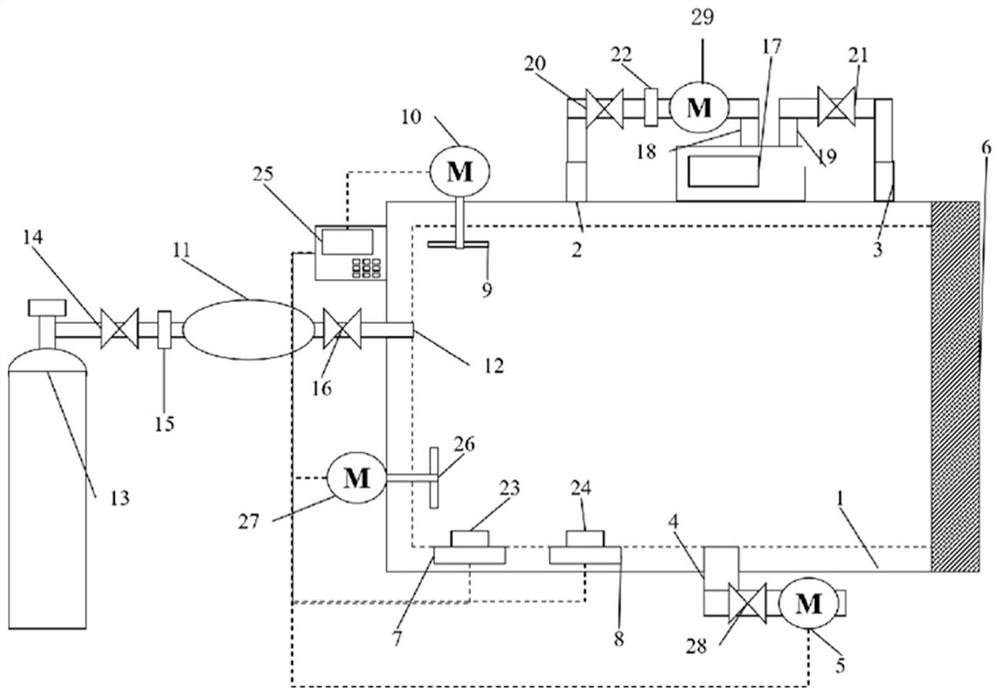

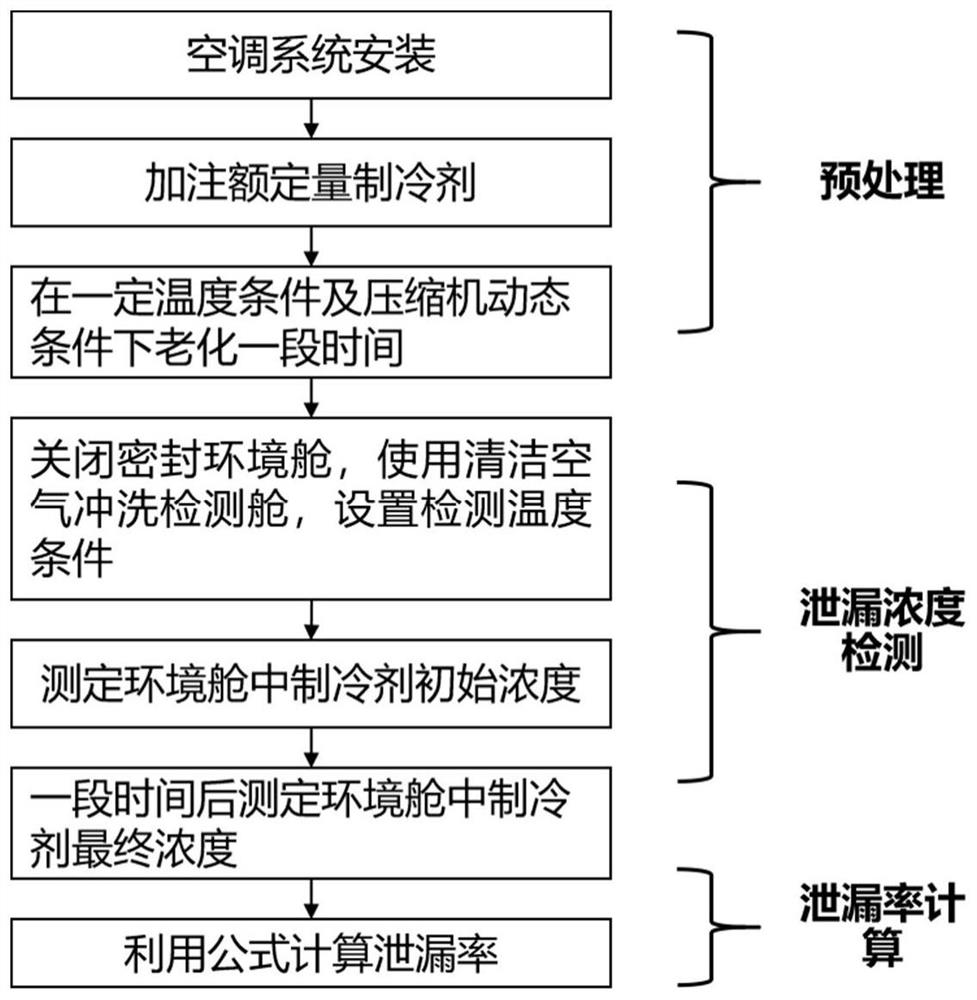

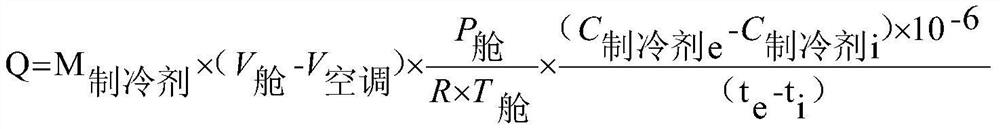

Device and method for detecting refrigerant leakage of automobile air conditioning system

PendingCN112611517AEasy to analyzeScientific analysisFluid-tightness measurement using fluid/vacuumTemperature controlAutomobile air conditioning

The invention provides a device and a method for detecting leakage of a refrigerant of an automobile air conditioning system and particularly relates to a device for detecting leakage of the refrigerant of the automobile air conditioning system. The system comprises an environment cabin, a temperature control system used for controlling the temperature of the environment cabin, a gas balance device used for controlling gas balance in the environment cabin, and a refrigerant analysis device used for the environment cabin, wherein the temperature control system is installed in the environment cabin, the environment cabin is provided with a gas inlet, the gas balancing device is connected with the gas inlet, the environment cabin is provided with a sampling port and a sample return port, one end of the refrigerant analysis device is connected with the sampling port, and the other end of the refrigerant analysis device is connected with the sample return port. According to the refrigerant leakage detection device, the leakage rate of the whole air conditioner system can be comprehensively and scientifically analyzed, and enterprises can explore and rectify the leakage level of the automobile air conditioner.

Owner:BEIJING CATARC DATA TECH CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com