Thermogravimetric analysis device and method for microwave pyrolysis sludge

A thermogravimetric analysis and microwave technology, applied in the direction of analyzing materials, measuring devices, material weighing, etc., can solve the problems of easy leakage of microwaves, harm to the surrounding environment and operators, and the influence of microwave precision weighing balances, so as to reduce the impact. , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

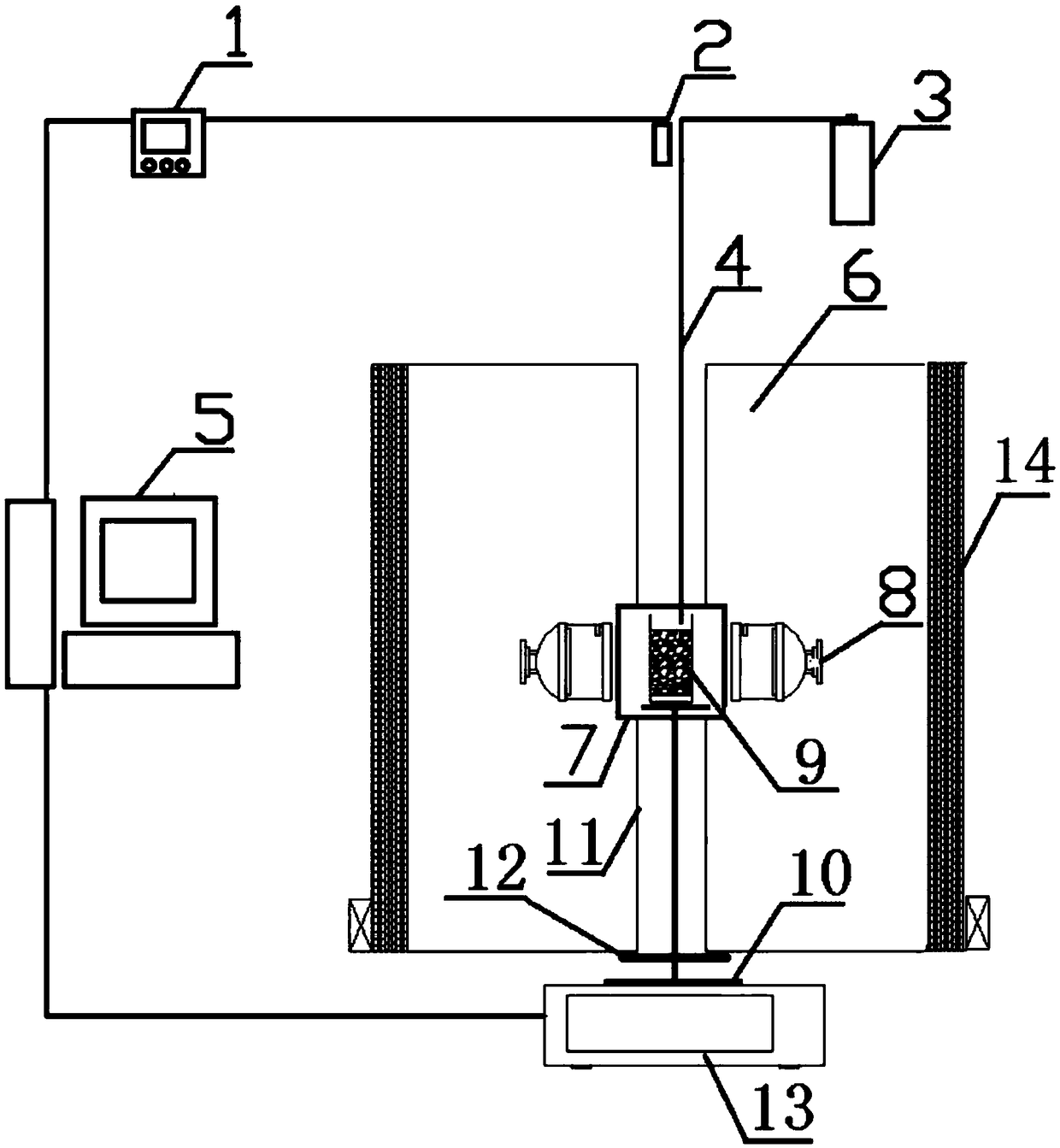

[0032] Such as figure 1 As shown, a microwave pyrolysis sludge thermogravimetric analysis device includes a microwave oven 6, an online weighing balance 13, a quartz support 10, a quartz beaker 9, a metal shielding ring 12, a quartz thin tube 4, an infrared thermometer 1 and a computer 5. The online weighing balance 13 is placed horizontally and fixedly supported, and can be supported on the ground or on a desktop or a workbench.

[0033] The microwave oven 6 is fixedly arranged above the online weighing balance 13; the microwave oven 6 has a microwave cavity 7 and two microwave magnetrons 8 inside, and the two microwave magnetrons 8 are fixedly connected to the left and right sides of the microwave cavity 7; The microwave oven 6 is provided with a vertical support channel 11, the support channel 11 runs through the microwave cavity 7 longitudinally, and the upper end and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com