Fotiaoqiang unfreezing method and quality analysis method of unfrozen Fotiaoqiang

An analysis method, the technology of Buddha jumping over the wall, applied in the analysis of materials, material analysis through electromagnetic means, food preservation, etc., can solve the problems of loss of flavor substances and taste substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0051] The invention provides a method for thawing the Buddha Jumping Wall, which includes placing the frozen Buddha Jumping Wall in an ultrasonic device, thawing in static water until the center temperature is 25°C, the frequency of the ultrasonic waves is 40KHz, and the temperature of the still water is controlled at 23-27°C. The present invention only defrosts the Buddha jumping wall by means of ultrasonic waves, and overcomes the technical prejudice that the technology in the art needs microwave and natural thawing to defrost the Buddha jumping wall. Only under the conditions of the above-mentioned ultrasonic frequency and water temperature can the thawed Buddha Tiaoqiang maintain the best quality.

Embodiment approach 2

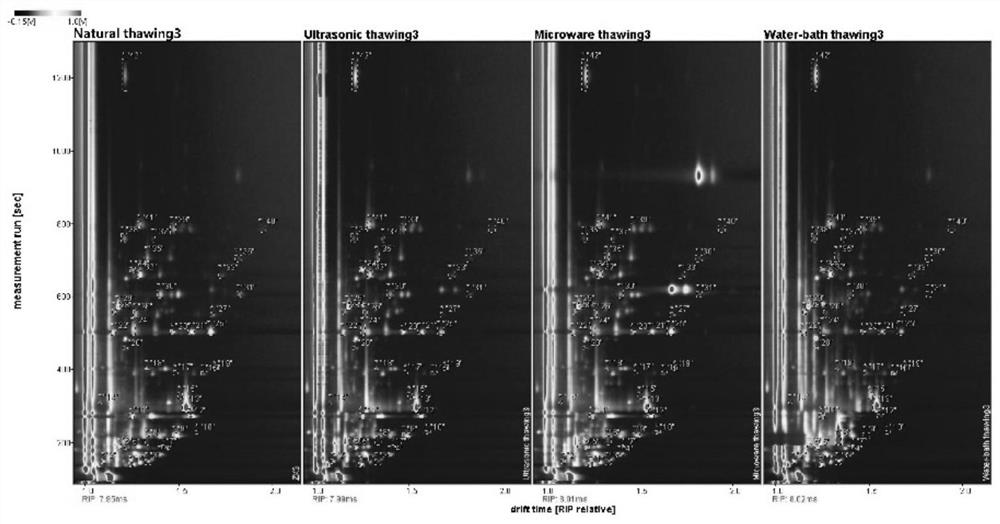

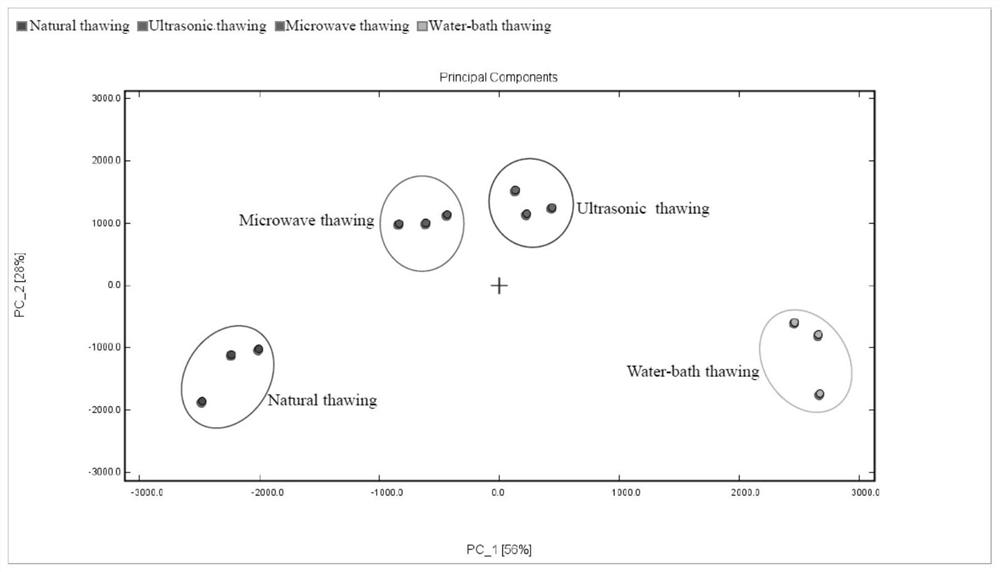

[0053] In order to comprehensively and scientifically analyze the impact of thawing methods on the quality of Buddha Tiaoqiang after thawing, the embodiment of the present invention provides an analysis method for the quality of Buddha Tiaoqiang after thawing.

[0054] As a well-known traditional food, the composition and content of flavor substances in Fotiaoqiang are important criteria for evaluating the quality of Fotiaoqiang. Therefore, the present invention comprehensively and scientifically analyzes the impact of thawing on Fotiaoqiang by measuring the content and composition of all flavor substances in the samples of Fotiaoqiang. .

[0055] Tests have shown that the thawing method has a greater impact on the aldehydes in the flavor substances of the Fotiaoqiang samples, and the aldehydes contribute the most to the overall flavor of the Fotiaoqiang. The present invention emphasizes the use of aldehydes as the evaluation index of flavor substances in Fotiaoqiang. In Fotia...

Embodiment 1

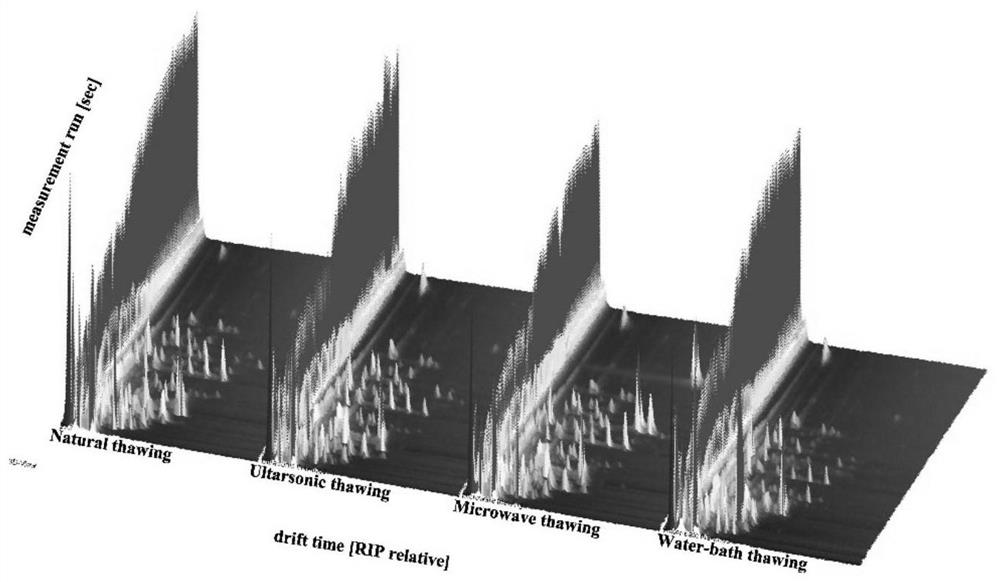

[0098] The analysis method of the quality of Buddha Jumping Wall after thawing in different thawing methods, including:

[0099] S1 Sample pretreatment: Take the Fotiaoqiang out of the -18°C freezer and randomly divide it into four groups. Use the following 4 ways to thaw until the center temperature is 25°C;

[0100] ①Ultrasonic thawing: Put the first group of Buddha jumping wall samples into the ultrasonic device, set the power to 200W, the frequency to 40KHz, and the temperature to (25±1)℃ for thawing;

[0101] ②Microwave thawing: Put the second group of Buddha Jumping Wall samples into a special microwave tray, and place them in a microwave oven with a frequency of 500W for thawing;

[0102] ③Water bath thawing: put the third group of Fotiaoqiang samples in a water bath to thaw, and the temperature is controlled at (25±1)℃;

[0103] ④Control group (natural thawing): The fourth group of Fotiaoqiang samples were thawed in a natural environment at room temperature (25±1)°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com