Intelligent on-demand feeding device

A feeding device and intelligent technology, applied in the field of agricultural livestock and poultry breeding, can solve the problems of uncontrollable feed supply, feed waste, etc., and achieve the effects of avoiding disaster losses, avoiding diseases, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

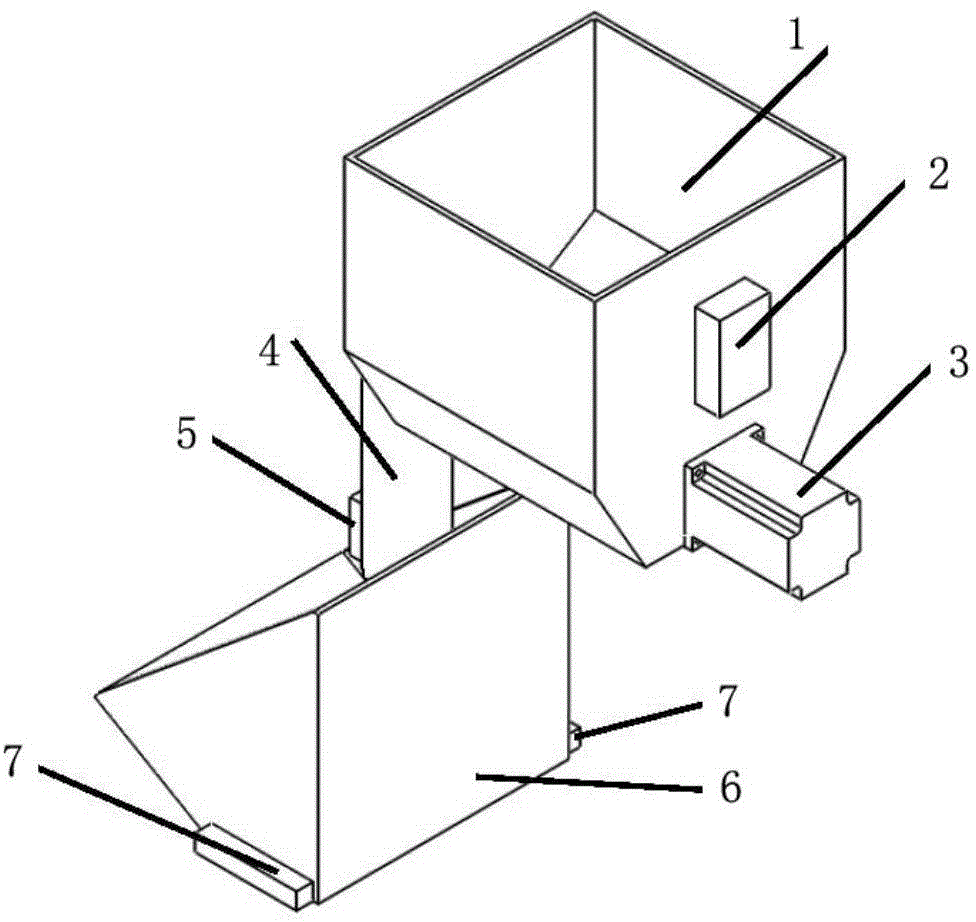

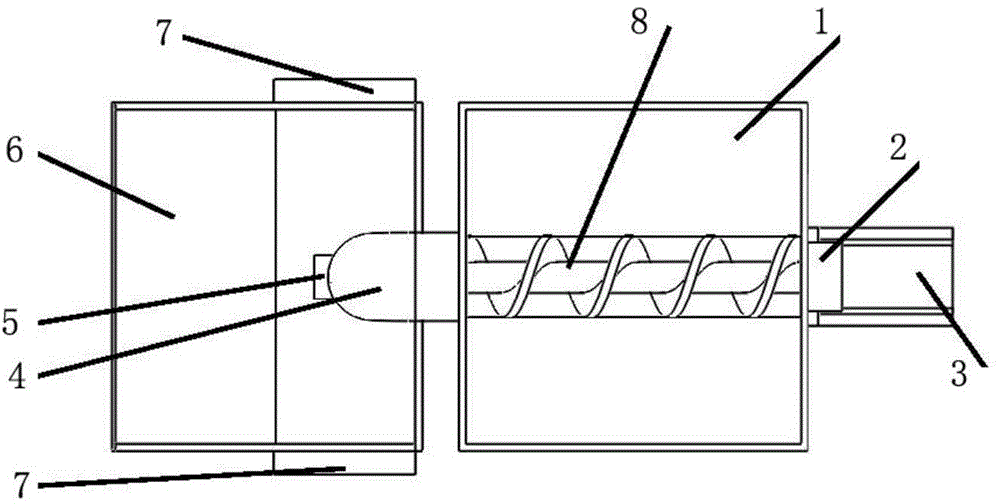

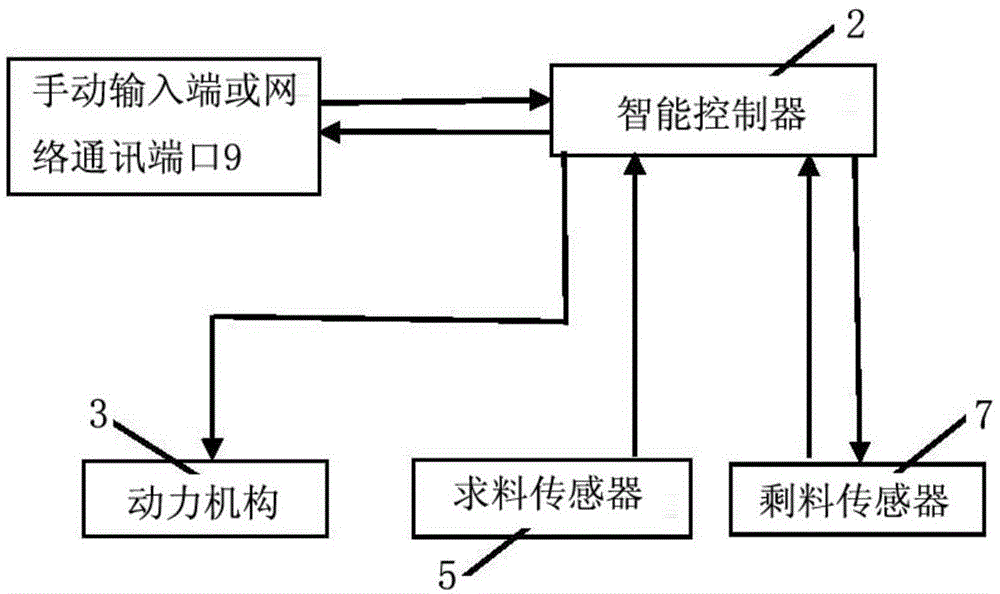

[0022] refer to Figure 1 to Figure 3 , the present embodiment includes a feeding structure and an intelligent control structure, and the intelligent feeding structure includes a storage box 1, a feeding tank 6, a feeding pipe 4, a transmission mechanism 8 and a power mechanism 3, and the intelligent control structure includes a Material sensor 5, a remaining material sensor 7 and an intelligent controller 2; the feeding port of the feeding pipe 4 is fixed on the bottom of the storage box 1 and communicates with the storage box 1, and the outlet of the feeding pipe 4 communicates with the feeding tank 6 The transmission mechanism 8 is movably arranged in the inside of the feeding pipe 4, and its power input end is connected with the power output end of the power mechanism 3; the power mechanism 3 is fixed on the side wall of the material storage box 1, and the control end of the power mechanism 3 is connected One of the control signal output terminals of the intelligent contro...

Embodiment 1

[0023] In this embodiment 1:

[0024] The transmission mechanism 8 is a conventional screw wheel transmission mechanism. The power mechanism 3 is a motor.

[0025] The charging sensor 5 is a conventional thermosensitive sensor. The remaining material sensor 7 is a combination of conventional infrared object measuring sensors, which is composed of a conventional infrared emitting module and an infrared receiving module. The intelligent controller 2 is composed of a combination of a conventional single-chip microcomputer and its peripheral devices, and a detection and control program is set according to a conventional built-in program form.

[0026] The working principle of the present embodiment 1 is as follows:

[0027] When the poultry has a need to eat, when the mouth or head of the poultry enters the detection range of the feed sensor 5, the feed sensor 5 captures the thermal infrared rays of the poultry, and sends a feed signal to the intelligent controller 2. Simultan...

specific Embodiment 2

[0029] The characteristics of this embodiment are: the left material sensor 7 is an image sensor, the intelligent controller 2 is an embedded computer, and the others are the same as the first embodiment.

[0030] The working principle of the present embodiment 2 is as follows:

[0031] When the poultry has a need to eat, when the mouth or head of the poultry enters the detection range of the feed sensor 5, the feed sensor 5 captures the thermal infrared rays of the poultry, and sends a feed signal to the intelligent controller 2. Simultaneously, intelligent controller 2 controls leftover material sensor 7 to work and collects the image data that feeds back; Intelligent controller 2 analyzes the image data fed back by leftover material sensor 7, when finding color, shape similar to the color, shape of known feed It is judged that there is leftover material when there is an object, otherwise it is judged that there is no leftover material. When the intelligent controller 2 rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com