Tobacco leaf curing method based on electronic nose smell monitoring technology

A curing method and electronic nose technology, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of the accuracy of the curing process and the low level of tobacco leaf aroma and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the present invention will be described in more detail below in conjunction with specific embodiments and accompanying drawings. In the following description, when detailed descriptions of existing prior art may obscure the subject matter of the present invention, such descriptions will be omitted here.

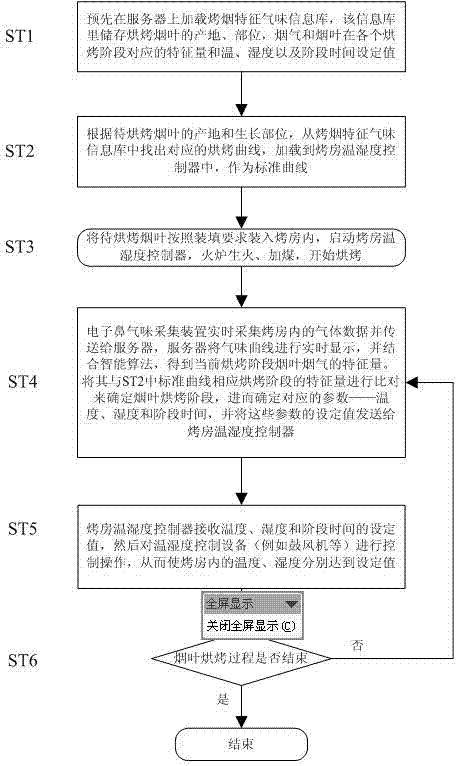

[0032] attached figure 1 It is a flow chart of a specific embodiment of the tobacco leaf curing control process method based on the electronic nose odor monitoring technology.

[0033] Step by step below, this embodiment is described in detail:

[0034] step ST1 : Load the flue-cured tobacco characteristic odor information database on the server in advance, which stores the origin of the cured tobacco leaves, the position of the tobacco leaves, the characteristic quantities of the smoke at each curing stage, and the corresponding temperature, Humidity setpoint and phase time setpoint.

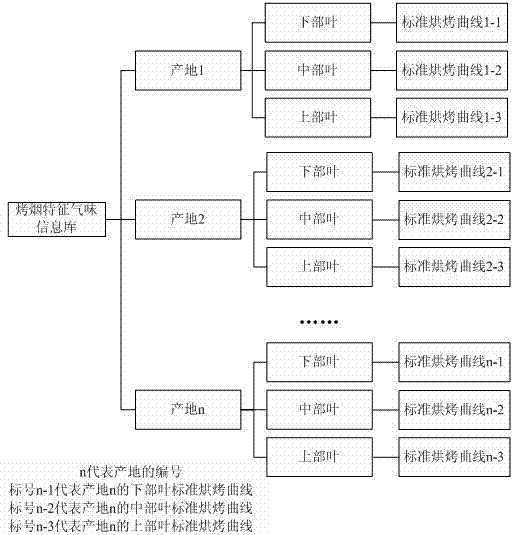

[0035] figure 2 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com