Detecting method of hydration process of gypsum slurry, and control method

A technology of detection method and control method, which is applied in the direction of manufacturing tools, auxiliary molding equipment, investigation stage/state change, etc., can solve the problems of little significance of production guidance, final setting time detection error, error, etc., so as to facilitate the production process control , Stabilize product quality, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

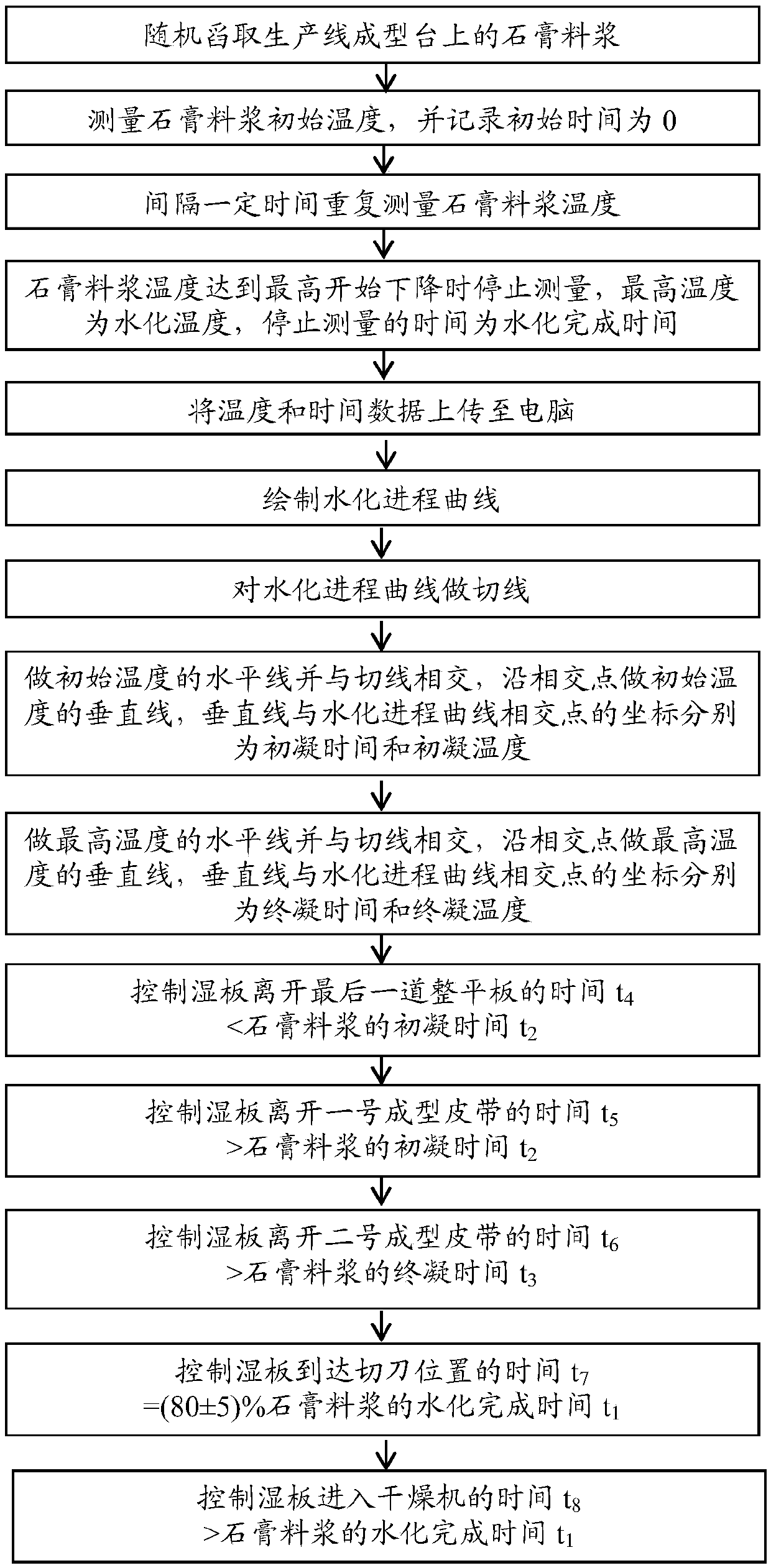

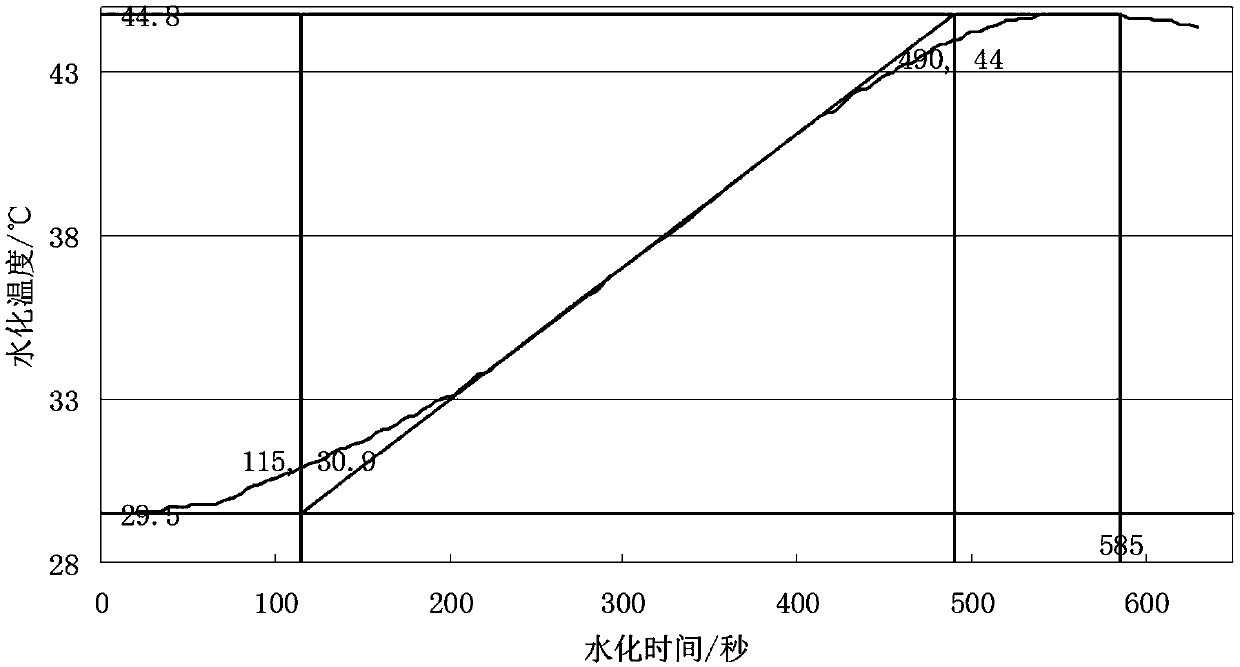

[0057] (1) Use the above detection method to detect the hydration process of the gypsum slurry, and record the temperature and time of the hydration process of the gypsum slurry, as follows:

[0058] The initial time is counted as 0, and the initial temperature of the gypsum slurry: 29.5°C;

[0059] Measure the temperature of the gypsum slurry every 5 seconds;

[0060] Stop timing when the temperature reaches the highest and starts to drop, and the termination time is t 1 : 585 seconds, the highest temperature: 44.8 ℃.

[0061] (2) draw the hydration process curve of the temperature of the gypsum slurry hydration process as a function of time, as figure 2 shown.

[0062] (3) Make a tangent to the hydration process curve, intersect with the initial temperature and the highest temperature horizontal line respectively, and draw a vertical line along the two intersection points.

[0063] (4) The first vertical line intersects the hydration process curve at the first point (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com