Electroplating method of terminal and terminal material belt structure

A terminal and strip technology, applied in the field of terminal strip structure, can solve problems such as inconvenience and increase terminal cost, and achieve the effects of convenient electroplating, increased electroplating speed, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

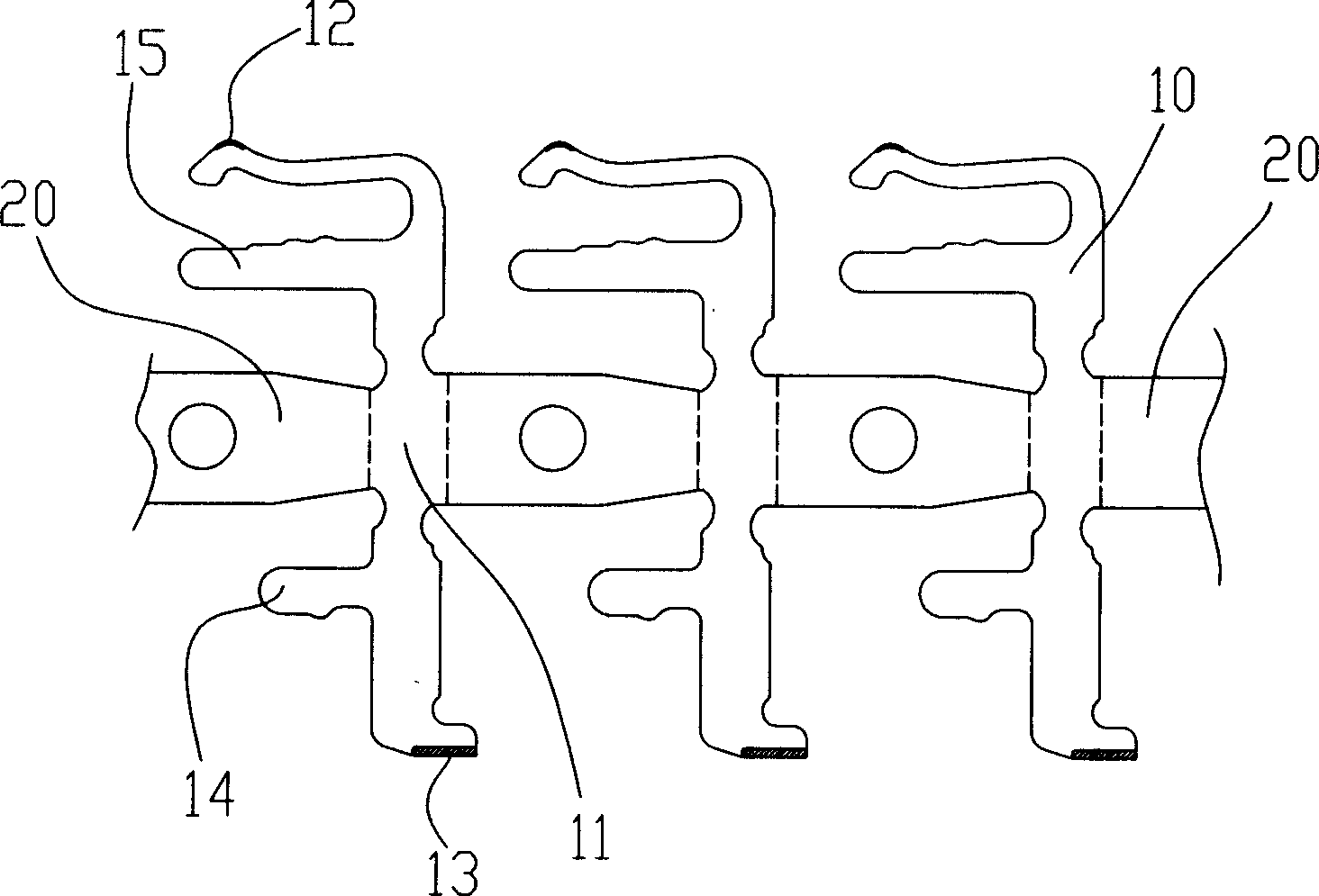

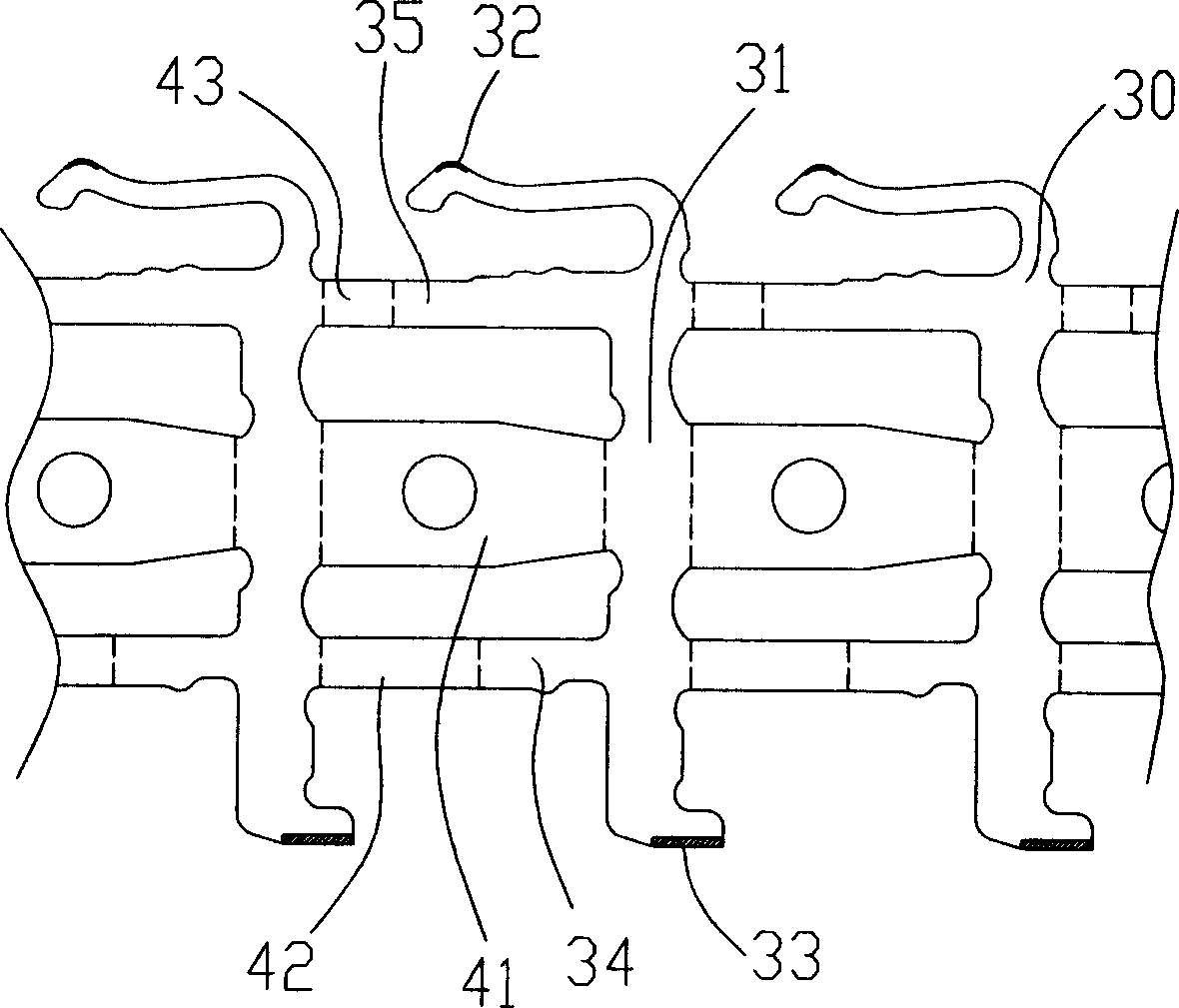

[0012] The electroplating method and the terminal strip structure of the terminal of the present invention will be further described below with reference to the accompanying drawings.

[0013] Generally, in order to enhance the corrosion resistance, wear resistance and conductivity of the terminal, it is necessary to plate one or more layers of metal on the terminal. The electroplating method of the terminal of the present invention first provides a step of providing a substrate (the substrate is a plate-shaped metal); then a step of punching the substrate out of the terminal and a strip; and finally a step of electroplating on the terminal.

[0014] Such as figure 2 As shown, the terminal strip structure using the above-mentioned electroplating method is stamped from a long strip of plate-shaped metal (not shown), which includes a terminal 10 and a strip 20, wherein the terminal 10 includes a main body 11 that faces from both sides of the main body 11 A contact part 12 and a wel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap