Connecting device, combined member and use thereof

A technology for connecting devices and combining components, which is applied to educational appliances, instruments, teaching models, etc., and can solve the problems of easy loosening and shrinking of the combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

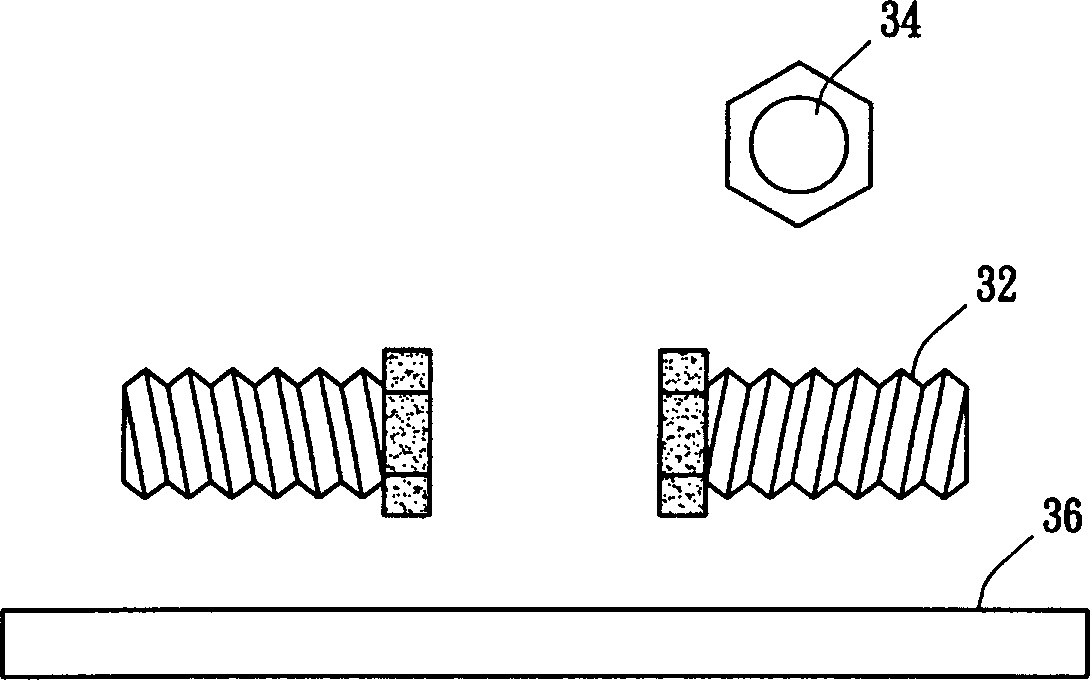

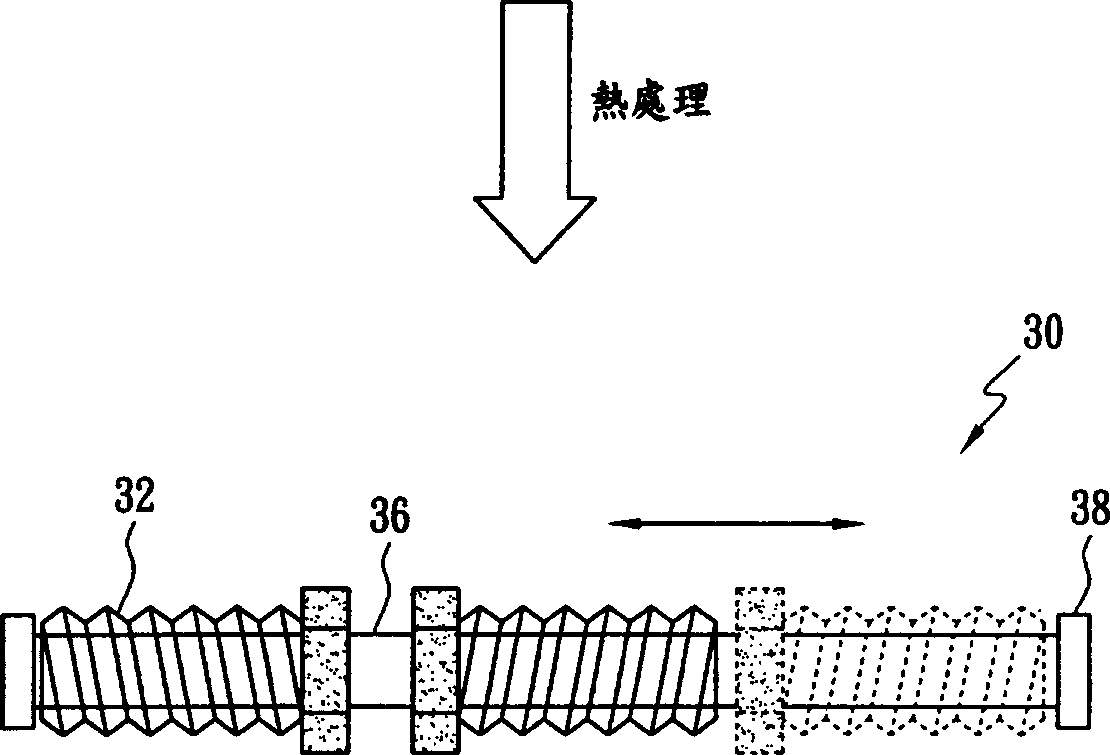

[0065]Referring to FIG. 2, FIG. 2(a) and FIG. 2(b) illustrate the first connecting device 30 of the present invention. The connection device 30 comprises two bolts 32 with a hollow 34 and a bearing member 36 slidably placed in the hollow 34, wherein the end of the bearing member 36 has a protrusion with a size (diameter) larger than the hollow 34 38. The preparation method of the connecting device 30 is to first place the bearing part 36 in the hollow 34 of the bolt 32, then perform a heat treatment to soften the end of the bearing part 36, and apply force to the end of the bearing part 36 to push inward. The protrusions 38 are formed to prevent the bolts 32 from detaching from the bearing member 36, but allow the bolts 32 to move between the two protrusions 38, as shown in FIG. 2(b). Preferably, the bolt 32 and the bearing part 36 of the connecting device 30 are made of plastic or metal.

[0066] image 3 It is the first combined component 40 of the present invention. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com