Apparatus of assemble and disassemble fuel injection valve

A fuel injection valve and fuel technology, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as shearing of nozzle clamping pins, and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

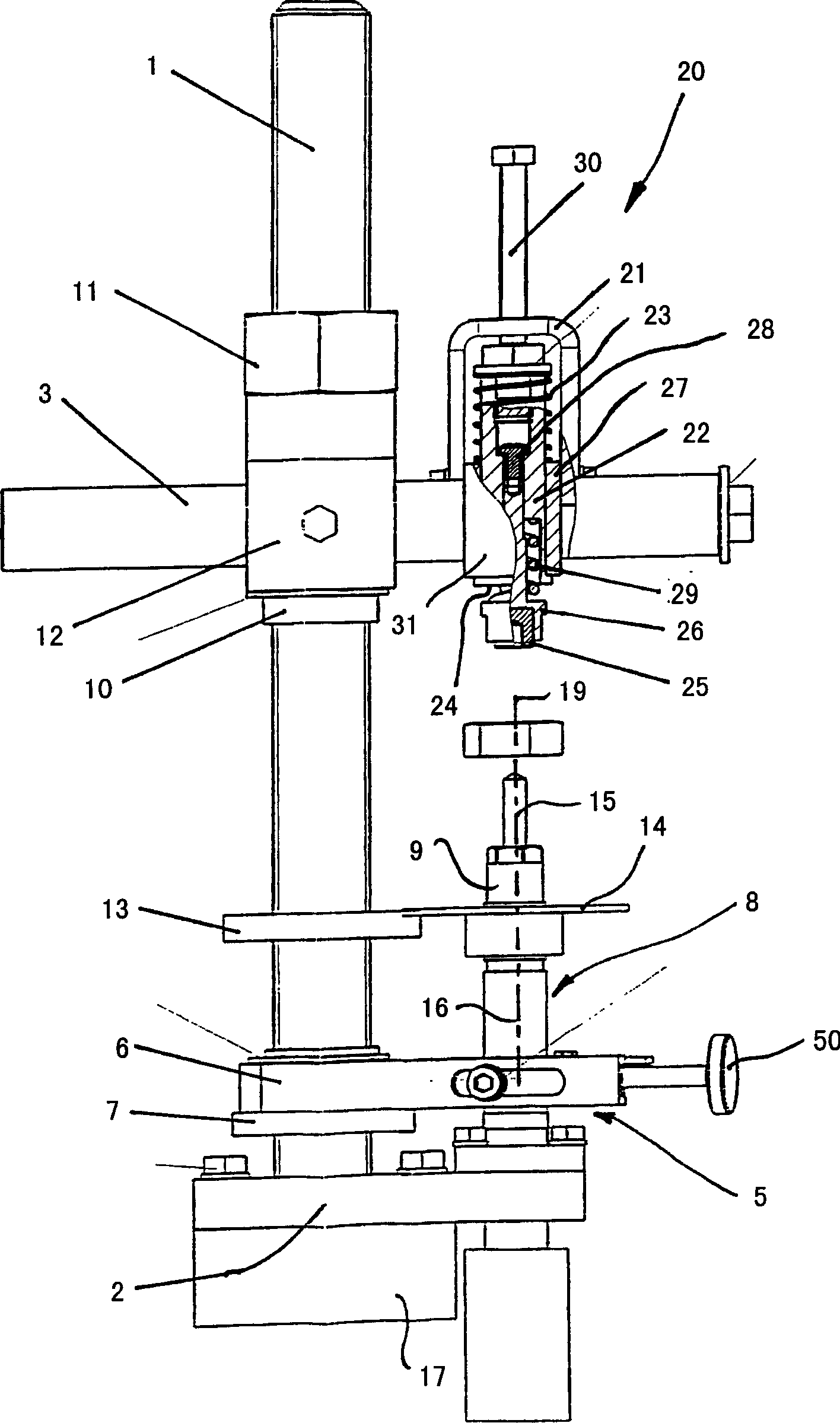

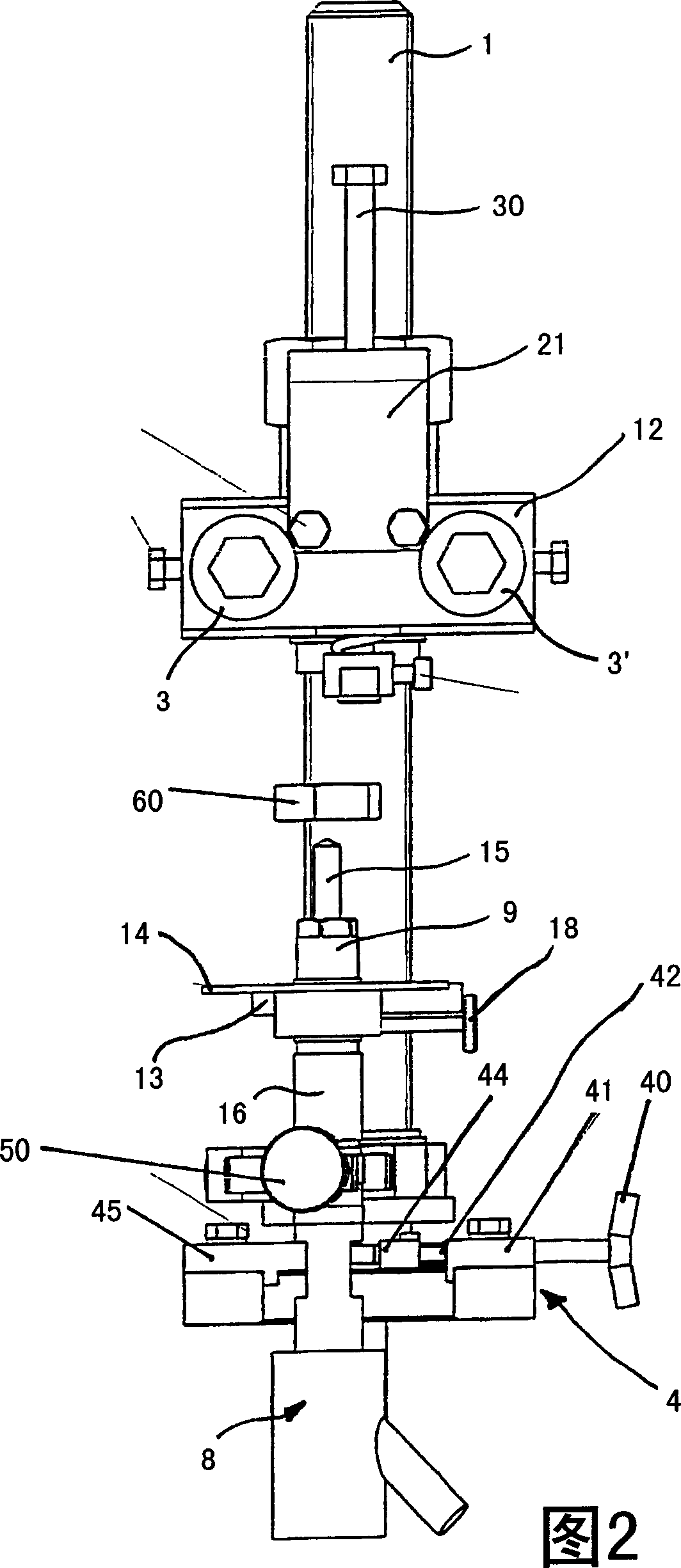

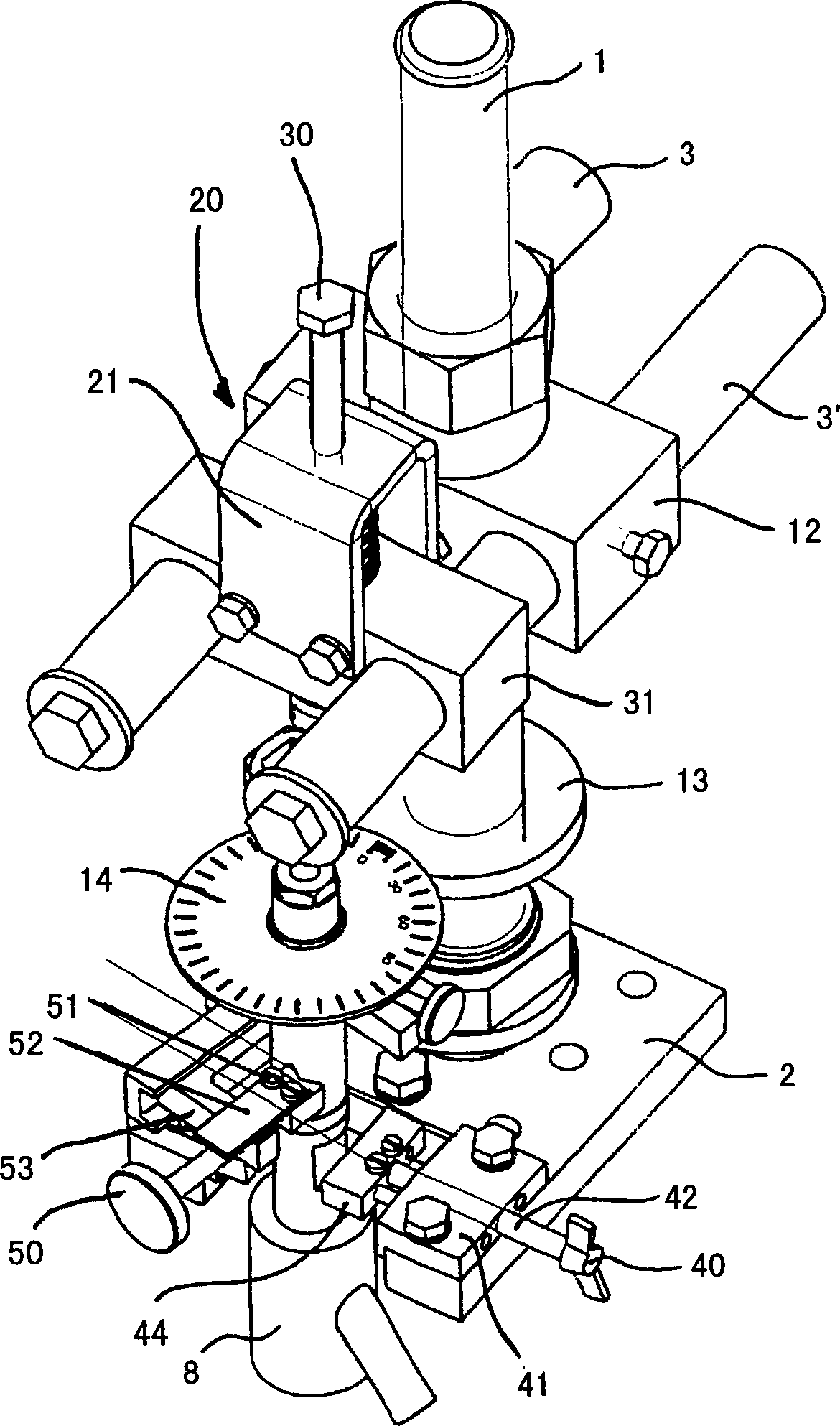

[0023] figure 1 A side view of the device of the present invention is shown in . Figure 2 shows a 90° rotated view of the device, image 3 A perspective view of the same device is shown, whereby all three figures are explained together below, wherein it should be noted that some parts of the device are only visible in one or two of these figures. The device has a basic frame comprising a guide bar 1 and a base plate 2 , wherein the guide bar 1 is threaded over its entire length. A holding element 17 can be fastened to the base plate 2 so that the device can be clamped in a vice. If the device is to be fastened directly on a table, there are holes in the base plate 2 for this purpose. A first holding device 4 for a fuel injection valve is screwed on or otherwise fastened to the base plate 2 , an injector 8 is shown here as an example, which is used in a common rail injection system. The first clamping device 4 comprises a wing nut 40 by means of which a screw 42 guided in a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap