Book binder

A stapler and nail groove technology, applied in the direction of binding, etc., can solve the problems of affecting safe use, large spring pressure, troublesome stapling, etc., and achieve the effects of improving work efficiency, safe use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

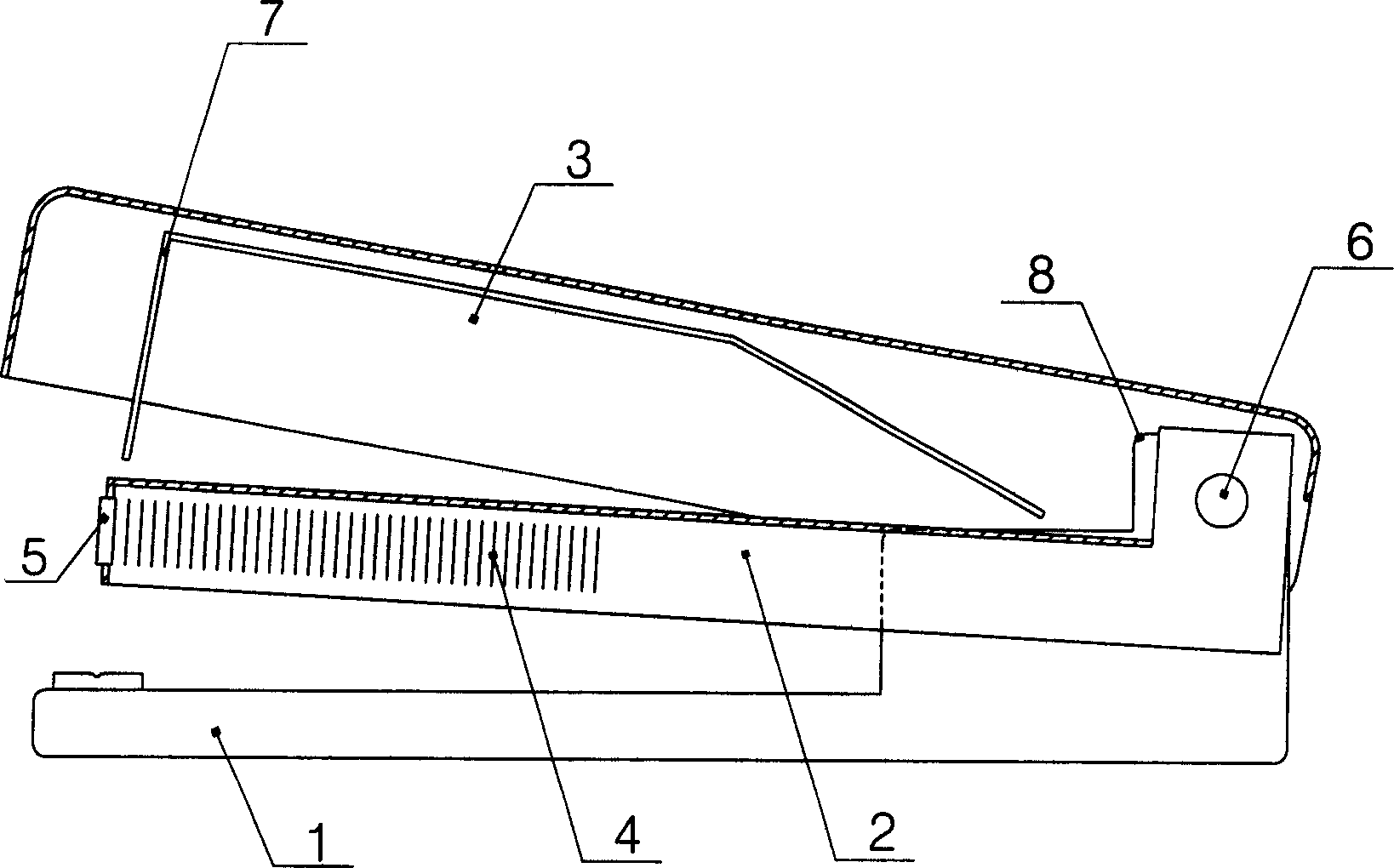

[0017] Such as figure 1 As shown, the stapler of the present invention comprises a base 1, a nail groove 2 and an upper cover 3, and the upper cover 3 is connected with a nail pressing piece 7, and the nail groove 2 and the upper cover 3 are hinged on the back of the base 1 through a movable shaft 6. End, nail slot 2 front end is equipped with a magnetic device 5. Described magnetic device 5 is the magnet sheet that embeds nail groove 2 front ends, also can be a magnet sheet that matches with nail groove 2 front ends, is fixed on nail groove 2 front ends, also can be that the front end part of nail groove 2 adopts magnetic material Manufactured or shaped after magnetization to make it magnetically attractive. Electromagnetic devices can also be installed at the nail groove 2 fronts, which have been adapted to the work of the automatic staple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap