Preparation method of carbon nanotube, carbon nanotube fiber

A carbon nanotube fiber, carbon nanotube technology, applied in the direction of carbon nanotube, nanocarbon, fiber chemical characteristics, etc., can solve the problems of unsuitable carbon nanotube force, low yield, carbon nanotube array tube length, etc., To achieve the effect of optimizing and stabilizing the atmosphere in the furnace, increasing the gas diffusion coefficient, and avoiding inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention provides a method for preparing carbon nanotubes, comprising the following steps:

[0040] S10. Obtain the substrate on which the catalyst layer is deposited, and load the substrate on which the catalyst layer is deposited into the reaction furnace of the chemical vapor deposition equipment under a protective gas atmosphere;

[0041] S20. the reaction furnace is evacuated to 10 -2 Below Torr, inject protective gas so that the pressure in the furnace is 150-300 Torr, and keep it for more than 20 minutes;

[0042]S30. Then, under the condition that the injection rate of the protective gas is constant and the pressure in the furnace is constant, the temperature is raised to 600-800° C., and carbon source gas is introduced to grow carbon nanotubes to obtain carbon nanotubes.

Embodiment 1

[0072] A method for preparing carbon nanotubes, comprising the steps of:

[0073] S11, using a vacuum electron beam method to deposit an iron-cobalt-nickel catalyst layer on the silicon substrate with a thickness of 35 nanometers. The silicon substrate size is 8 inches.

[0074] S21. The substrate is loaded into the CVD furnace of the chemical vapor deposition equipment under the protection of the inert gas helium.

[0075] S31, the CVD furnace is vacuumed to 10 -2 Torr, and then inject protective gas helium, the pressure in the furnace is kept at 200 Torr, the helium flow rate is set at 500 sccm, and it is kept for 30 minutes.

[0076] S41, heating the CVD furnace to a specified temperature of 650°C.

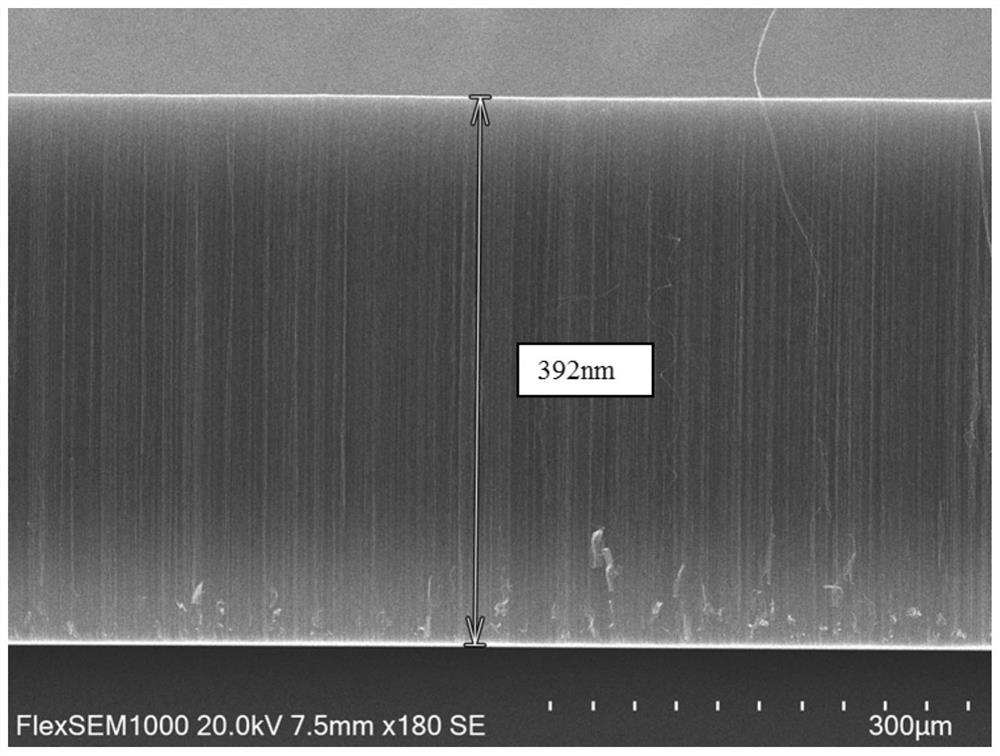

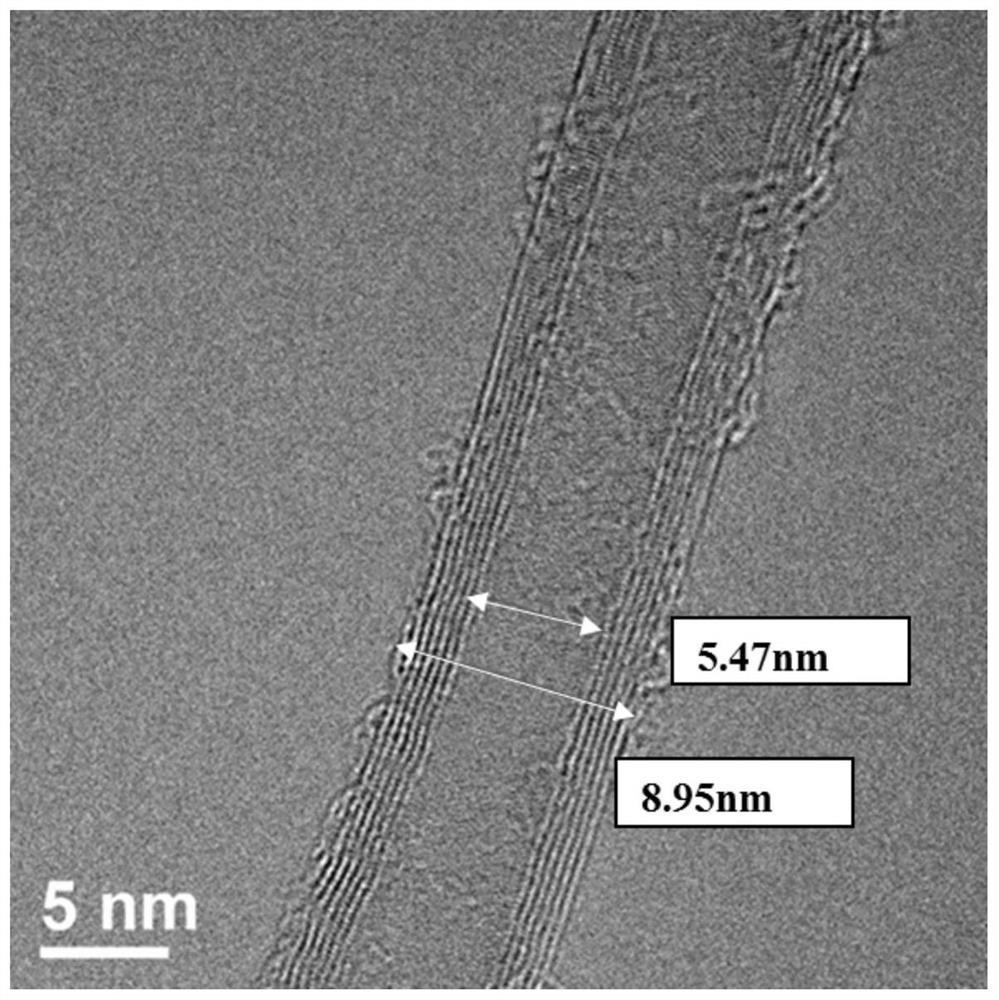

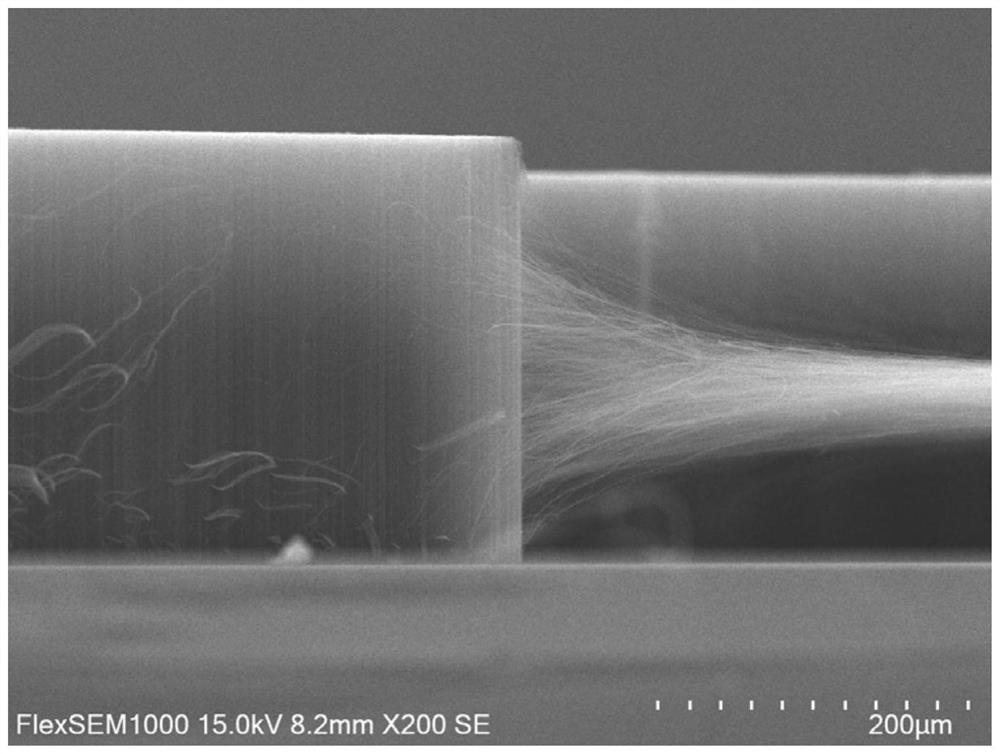

[0077] S51. Keep the flow rate of helium constant, and at the same time, the pressure in the furnace is stabilized at 200 Torr. At the same time, ethylene gas and hydrogen gas are introduced in equal proportions, each flow rate is 30 sccm, and the growth of the carbon nanotu...

Embodiment 2

[0080] A method for preparing carbon nanotubes, comprising the steps of:

[0081] S12, using a vacuum electron beam method to deposit an iron-cobalt-nickel catalyst layer on the silicon substrate with a thickness of 30 nanometers. The silicon substrate size is 8 inches.

[0082] S22. The substrate is loaded into the CVD furnace of the chemical vapor deposition equipment under the protection of the inert gas helium.

[0083] S32, the CVD furnace is vacuumed to 10 -2Torr, and then inject protective gas helium, the pressure in the furnace is kept at 200 Torr, the helium flow rate is set at 800 sccm, and it is kept for 30 minutes.

[0084] S42, heating the CVD furnace to a specified temperature of 700°C.

[0085] S52. Keep the flow rate of helium constant, and at the same time, the pressure in the furnace is stable at 200 Torr. At the same time, ethylene gas and hydrogen gas are introduced in equal proportions, each flow rate is 40 sccm, and the growth of the carbon nanotube ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com