Silk thread clamping, positioning and tensioning device for synchronous rotary table

A technology of clamping, positioning and tensioning devices, applied in the field of synchrotron radiation, can solve the problems of no adjustment mechanism, inaccurate rotation radius, and inability to ensure clean and sharp pulley grooves, and achieves the effect of stable structure and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

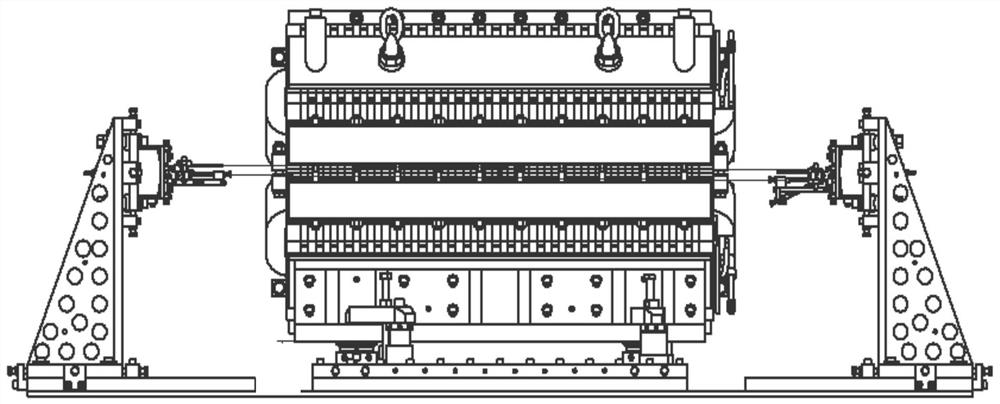

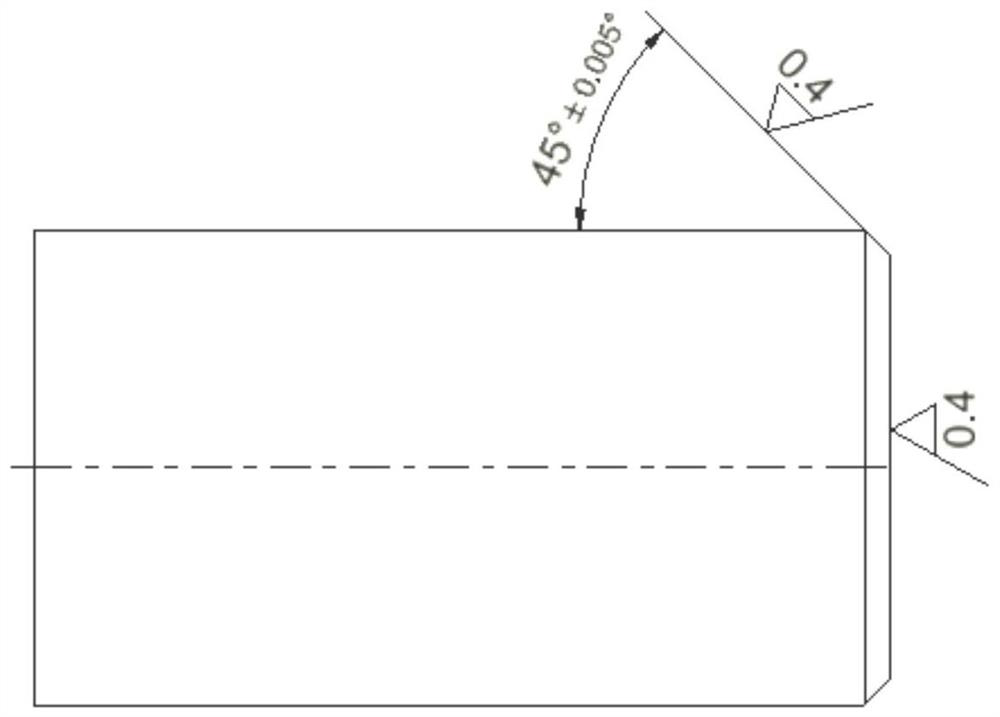

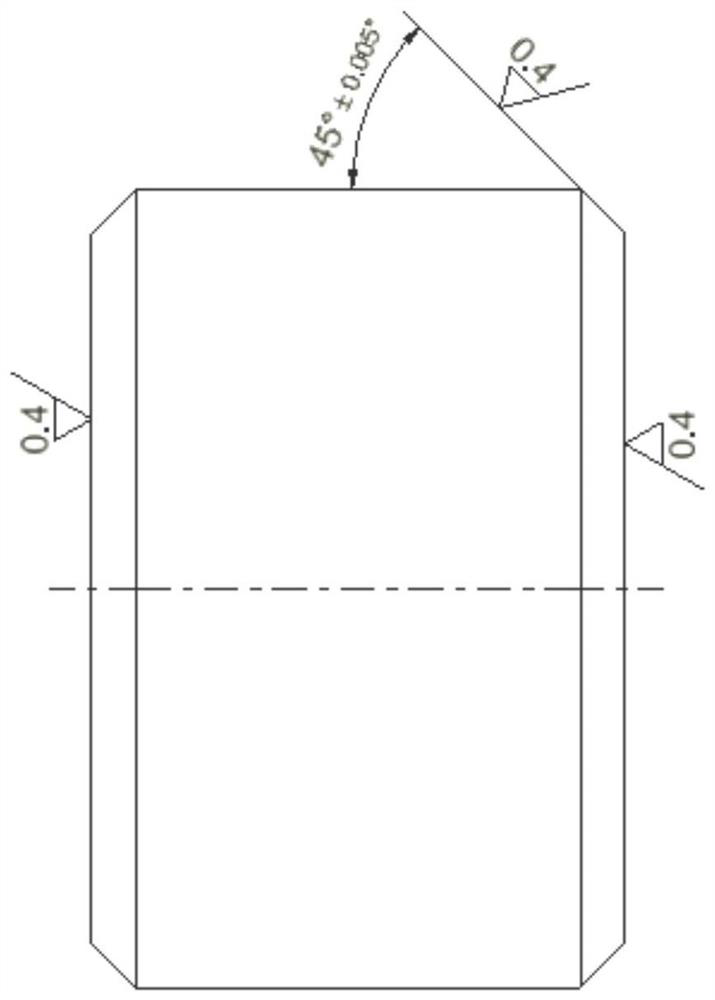

[0040] Such as figure 1 As shown, the present invention includes two turntables facing each other. The start and end of the silk thread are fixed on the turntable on the same side, referred to as the turntable on the open side; the middle part of the thread is fixed on the turntable on the other side, referred to as the turntable at the closed end of the silk thread. figure 2 It is a one-end ceramic column structure, and one end is 45° conical, which is called a single-cone ceramic column; image 3 It is the structure diagram of the middle ceramic column, both ends are tapered, which is called double-cone ceramic column. Figure 5 The two pairs of tops of the three ceramic pillars and cones in the middle are closely attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com