Screwing-embedding integrated rapid reset key-locking threaded insert mounting device

An installation device and screw sleeve technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of excessive hammering force, breaking, and bending of pins, and achieve the effect of avoiding bumps and dents, high production efficiency, and avoiding bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

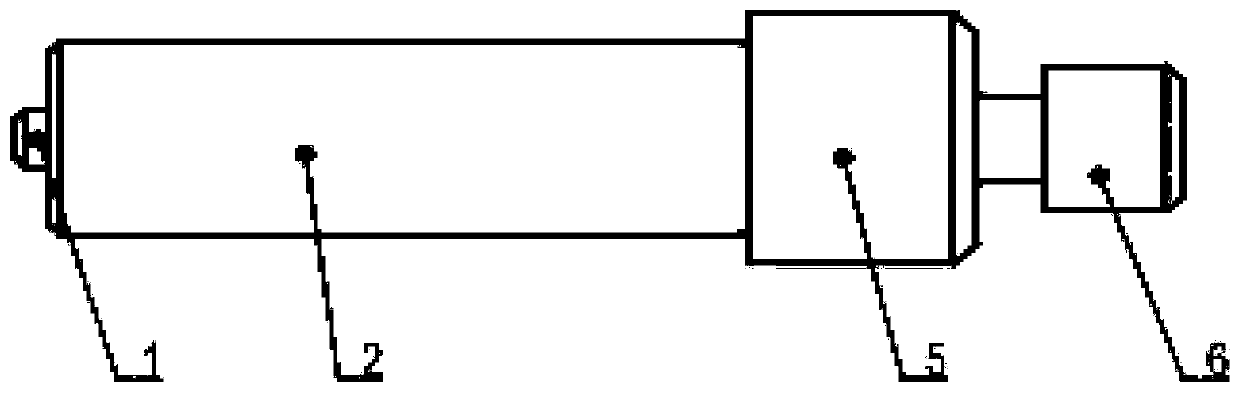

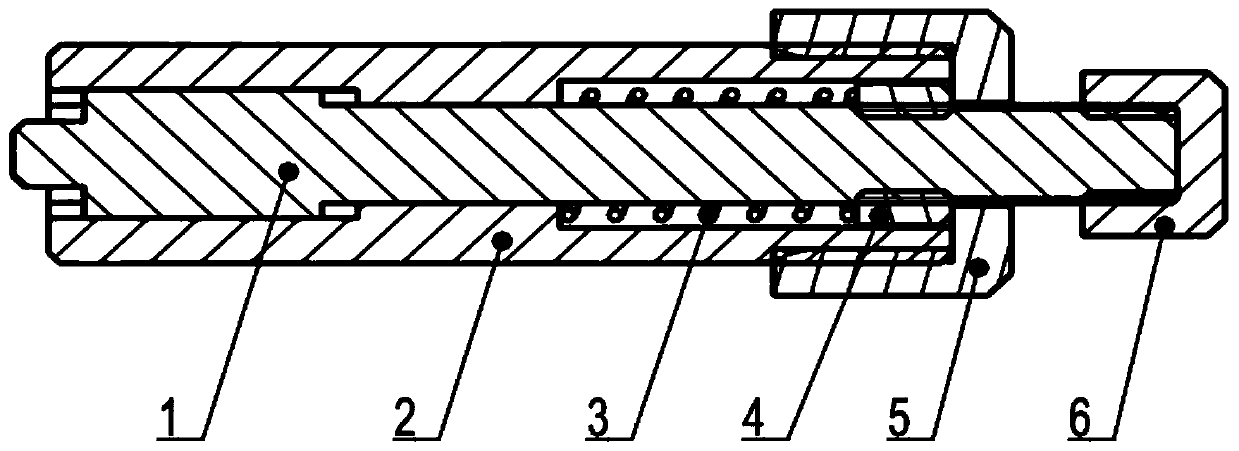

[0021] Such as Figure 1 to Figure 4 As shown, the present invention is used for the installation of bolt screw sleeve and comprises guide rod 1, sleeve 2, spring 3, block 4, gland 5 and end cap 6, and guide rod 1 front section has four guide keys, and sleeve The four internal guide grooves are matched, the spring 3 and the stopper 4 are inserted into the sleeve 2 through the rear end of the guide rod 1 in sequence, the gland 5 is installed on the rear end of the sleeve to press the stopper 4, and the end cover 6 is installed on the guide rod 1 rear end, guide rod 1, sleeve 2, spring 3, stopper 4, gland 5 and end cap 6 are all coaxially connected.

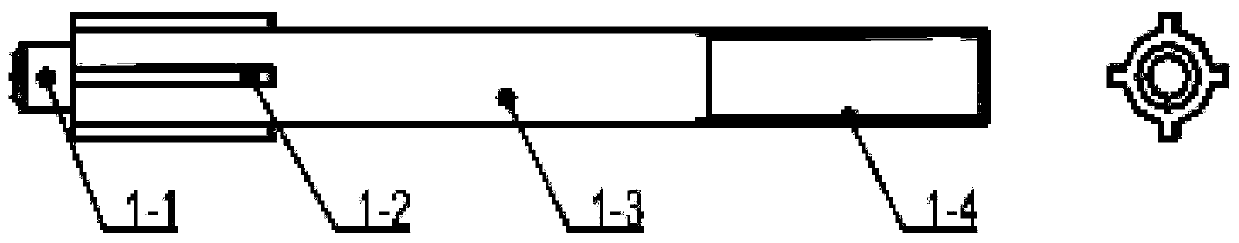

[0022] When the screw sleeve is screwed in, the boss 1-1 in the guide rod 1 cooperates with the screw sleeve, and the four guide grooves 2-1 in the sleeve 2 cooperate with the four bolts to realize the dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com