Spiral concrete prefabricated tubular pile for overhead transmission line

A technology for overhead transmission lines and prefabricated pipe piles, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as increased project investment costs and loosening, and achieves improved tensile capacity, prevention of loosening, and reduction of concrete consumption. the effect of material and cost inputs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

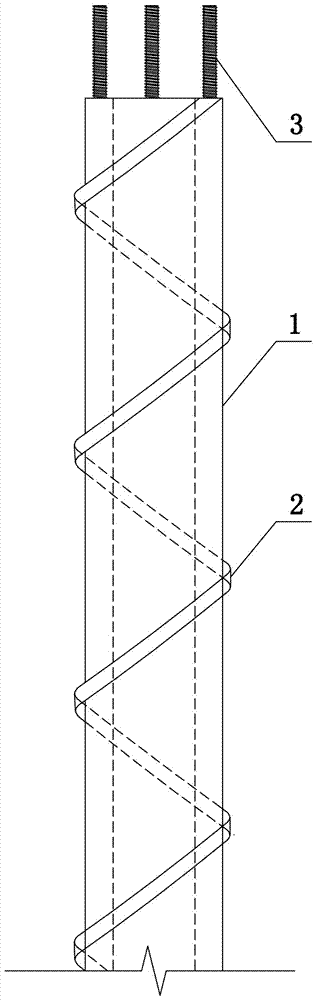

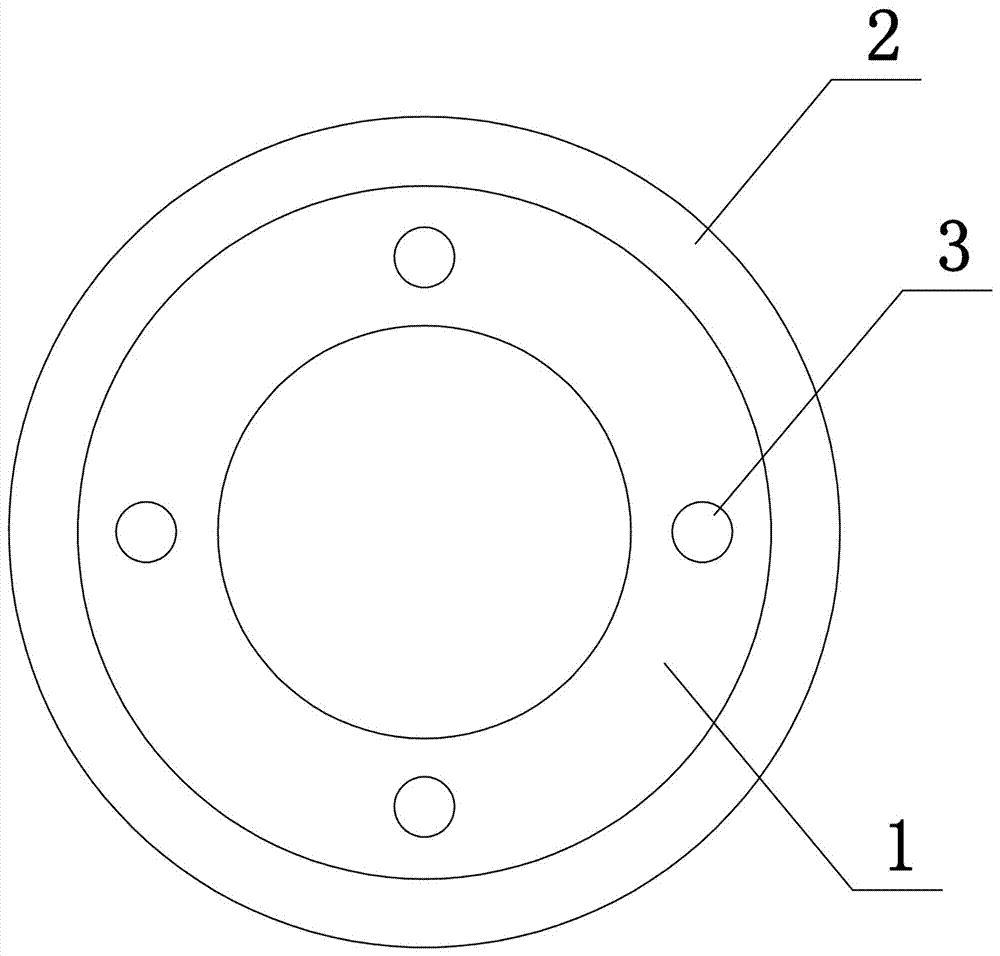

[0031] Such as Figure 1 to Figure 3 As shown, the present invention includes a pipe pile main body 1 and a spiral protrusion 2 integrally formed on the outer wall of the pipe pile main body. The upper end surface of the preset connection bolt 3.

[0032] The manufacturing process of the present invention comprises the following steps: the first step is to manufacture the mould, the mold adopts a steel structure including a flange-connected left half-ring mold and a right half-ring mould, and the left half-ring mold and the right half-ring mold are produced by a stamping device. Matching spiral grooves; the second step is to make a steel frame, and preset connecting bolts on the upper end of the steel frame to accept the lower end of the tower; the third step is to set the mold on the outside of the steel frame and pour concrete on the mold At the same time, the centrifugal equipment is used to drive the mold and the steel frame to rotate to ensure that the concrete is evenly...

Embodiment 2

[0035] Such as Figure 4 As shown, the present invention includes a pipe pile main body 1 and a spiral protrusion 2 integrally formed on the outer wall of the pipe pile main body. The upper end surface of the main body 1 is preset with a connecting bolt 3 , a backing plate 4 is sleeved on the connecting bolt 3 , and a disc spring assembly 5 is arranged between the lower end surface of the backing plate 4 and the upper end surface of the pipe pile main body 1 .

[0036] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the disc spring assembly 5 and the backing plate 4 are sleeved on the connecting bolts. In the case of swaying, the disc spring assembly 5 provides sufficient deformation space for the lower end of the pole tower, thereby preventing hard damage to the tower body, cross arms or hanging points of the pole tower, and improving the stability and reliability of the present invention during use.

Embodiment 3

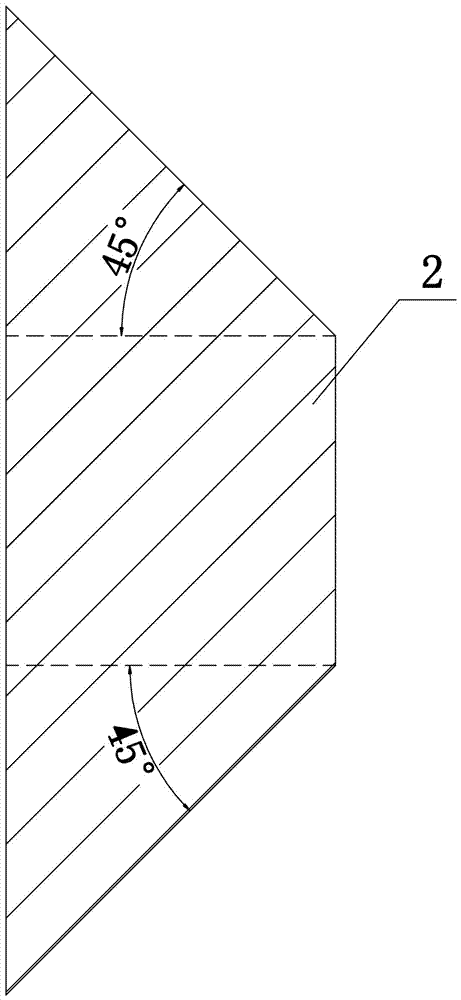

[0038] Such as Figure 5 and Figure 6 As shown, the present invention includes a pipe pile main body 1 and a spiral protrusion 2 integrally formed on the outer wall of the pipe pile main body. The pipe pile main body 1 is a hollow columnar structure. The upper end surface of the pipe pile main body 1 is preset with a connecting bolt 3, the connecting bolt 3 is sleeved with a backing plate 4, and a disc is set between the lower end surface of the backing plate 4 and the upper end surface of the pipe pile main body 1. The spring component 5 and the pile tip 6 are integrally formed at the lower end of the pipe pile main body 1, and the outer wall of the pile tip 6 is integrally formed with a spiral protrusion 2 .

[0039] The structure of this embodiment is basically the same as that of Embodiment 2. The difference is that there are many spiral protrusions 2 and the end faces are in a triangular structure. In the stone environment, the structural design can quickly screw the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com