Pipeline type steam purger

A purging device and pipeline-type technology, applied in the field of fluid transmission, can solve the problems of short life, easy fire and explosion, rot, etc., and achieve the effect of long life, safe use, and non-perishable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

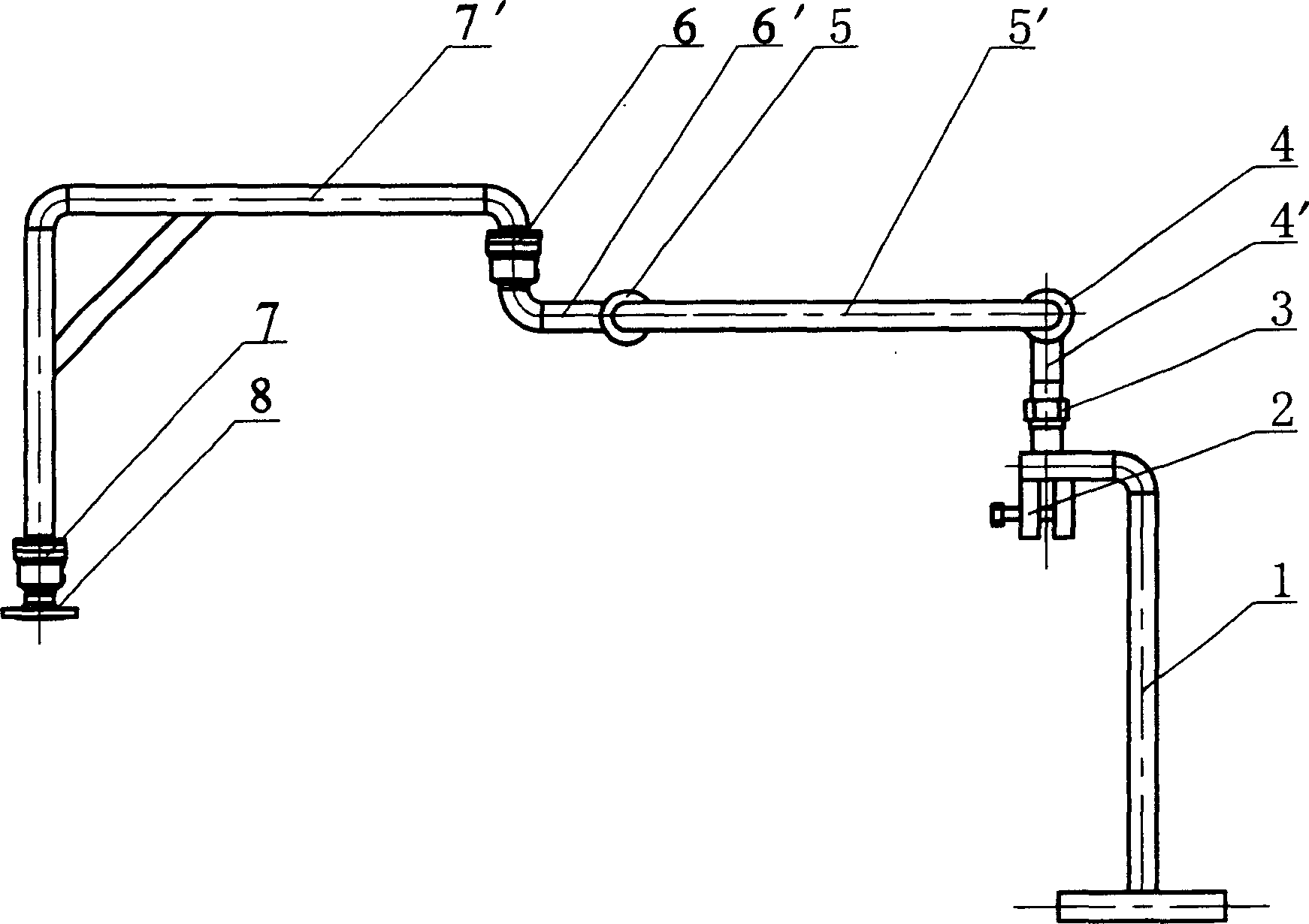

[0007] Such as figure 1 As shown, the device is divided into two parts, the movable metal pipe and the steam purge pipe, consisting of the rotary joints 4, 5, 6, 7 and the corresponding metal pipes 4', 5', 6', 7' such as figure 1 The sequence shown is connected with each other to form a movable metal pipe. According to the actual situation, there may be one or more rotary joints. The steam purge pipe is composed of a metal pipe 1 with a horizontal pipe and a tank clip 2 fixed on the metal pipe. One end of the movable metal pipe is connected to the steam purge pipe by a pipe connection joint 3 . The other end of the movable metal pipe is connected with the high neck flange 8 . When in use, first connect the high-neck flange 8 to the steam supply pipeline, then insert the steam purge pipe vertically into the tank, and fix its upper end at the tank mouth with a tank card, and then use the pipe connection joint to connect the movable After the metal pipe is connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com