High-temperature high-pressure self-sealing gate valve with double flat shutter board

A high-temperature, high-pressure, self-sealing technology, applied to sliding valves, valve devices, engine components, etc., can solve problems such as scratches on sealing surfaces, internal leakage, and poor sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is specifically described below in conjunction with accompanying drawing:

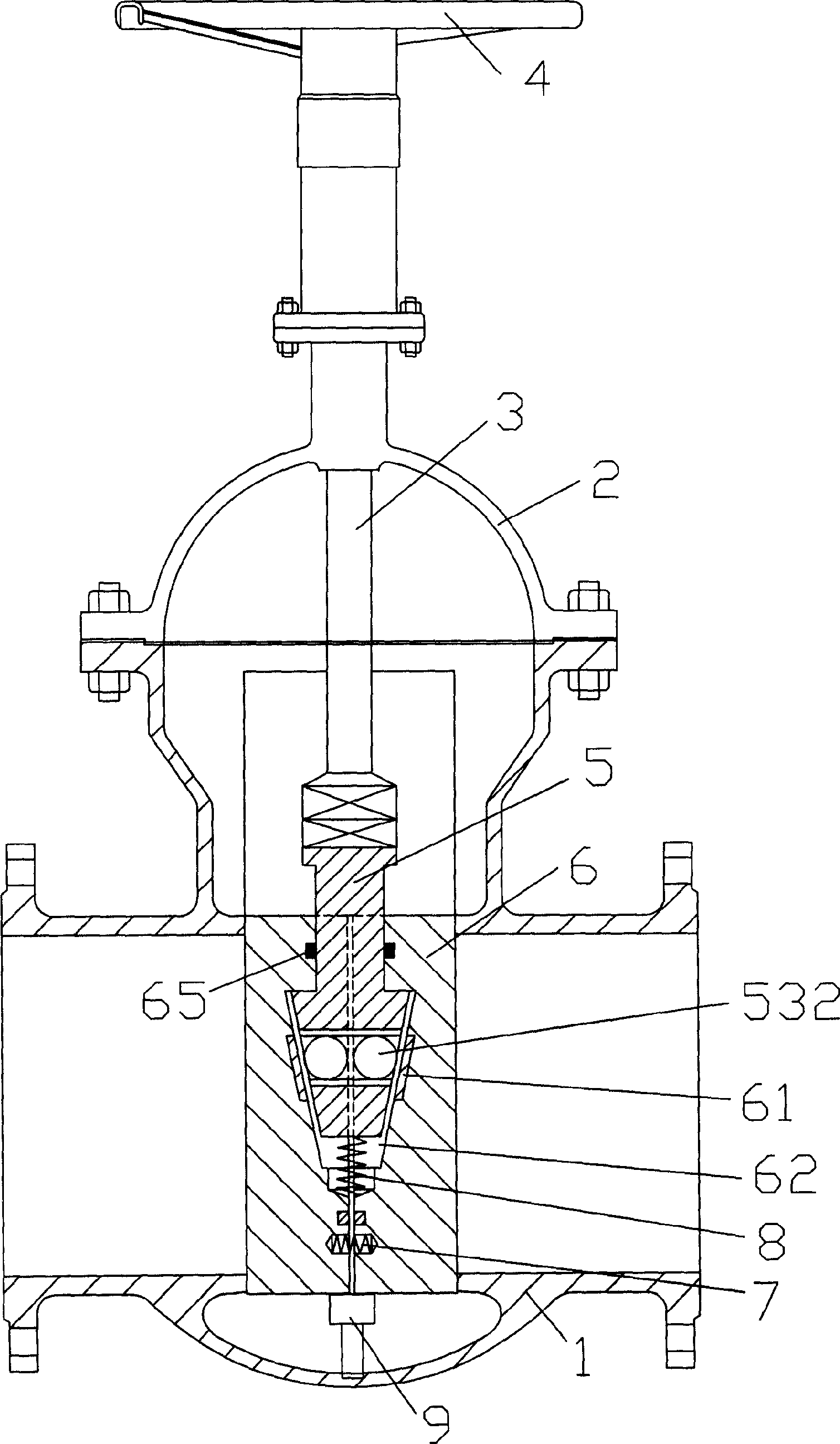

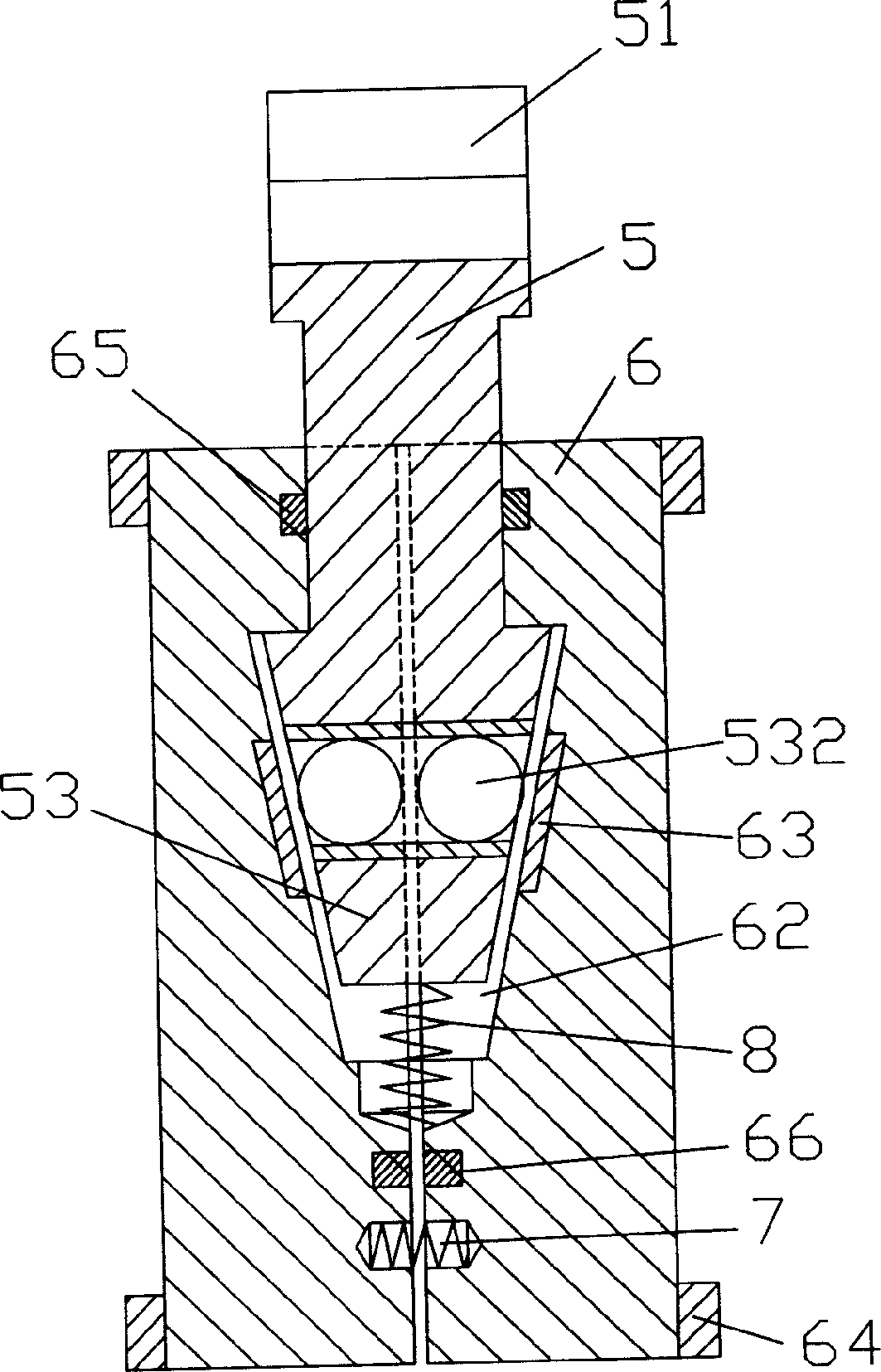

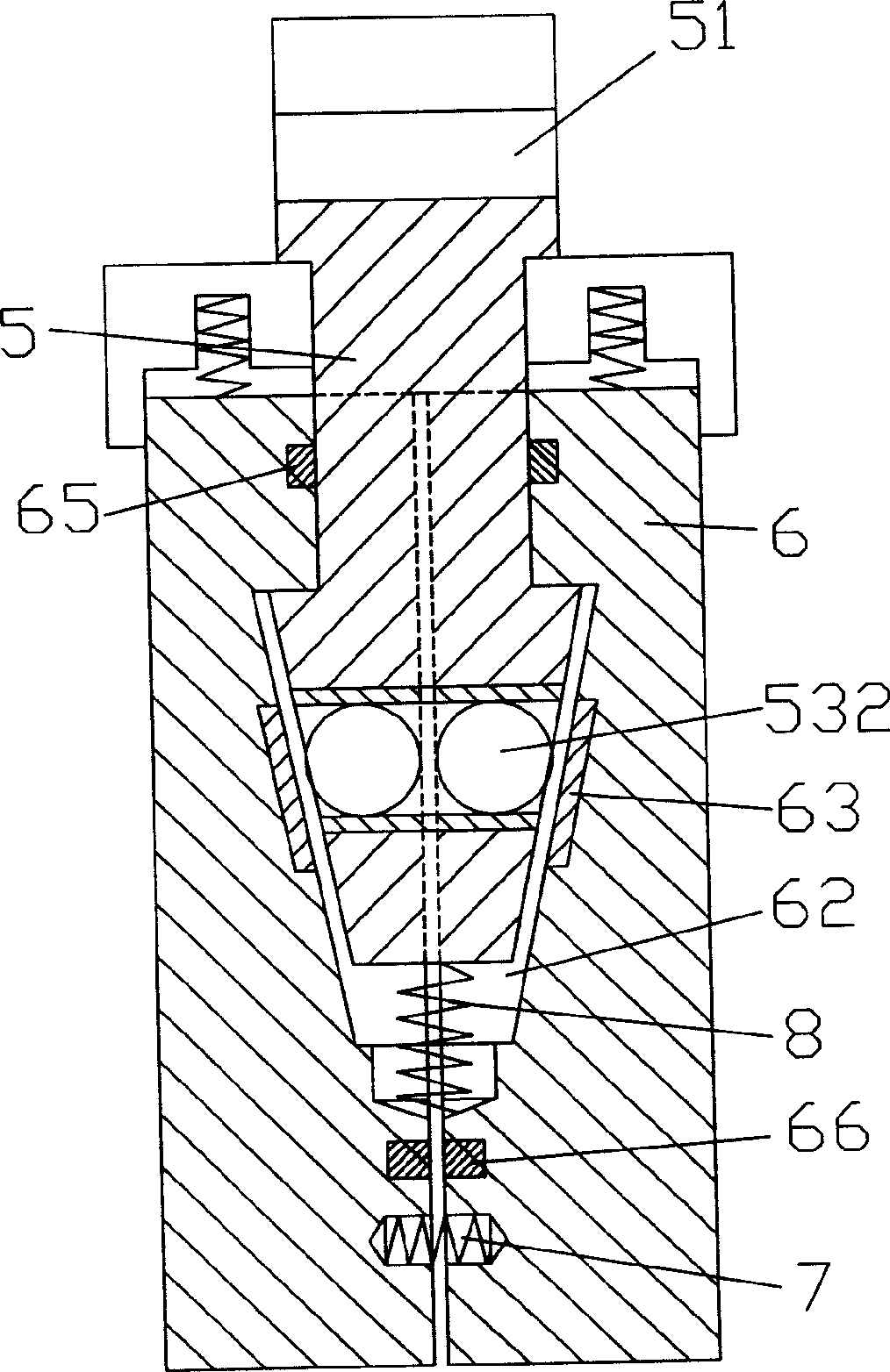

[0024] Such as figure 1 , 2 As shown, the high temperature and high pressure self-sealing double-plate gate valve of the present invention includes a valve body 1, a valve cover 2, an operating screw 3 and an operating hand wheel 4 are arranged on the upper valve cover 2, and the valve body 1 is provided with a valve connected to the operating screw 3. A moving gate mechanism, the valve body 1 is provided with a sealing surface that matches the gate in the gate mechanism. The gate mechanism includes a central push rod 5 and two oppositely arranged gates 6, such as image 3 , 4 As shown, the central push rod 5 includes an upper end connector 51, a neck 52 and a wedge-shaped lower end 53. The upper end connector 51 is provided with a card slot 511 for locking with the operating screw 3, and the lower end 53 is opposite. Its vertical axis is a symmetrical wedge-shaped head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com