Compressor

A compressor and pressure setting technology, applied in the field of compressors, can solve problems such as abnormal temperature rise on the discharge side, and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

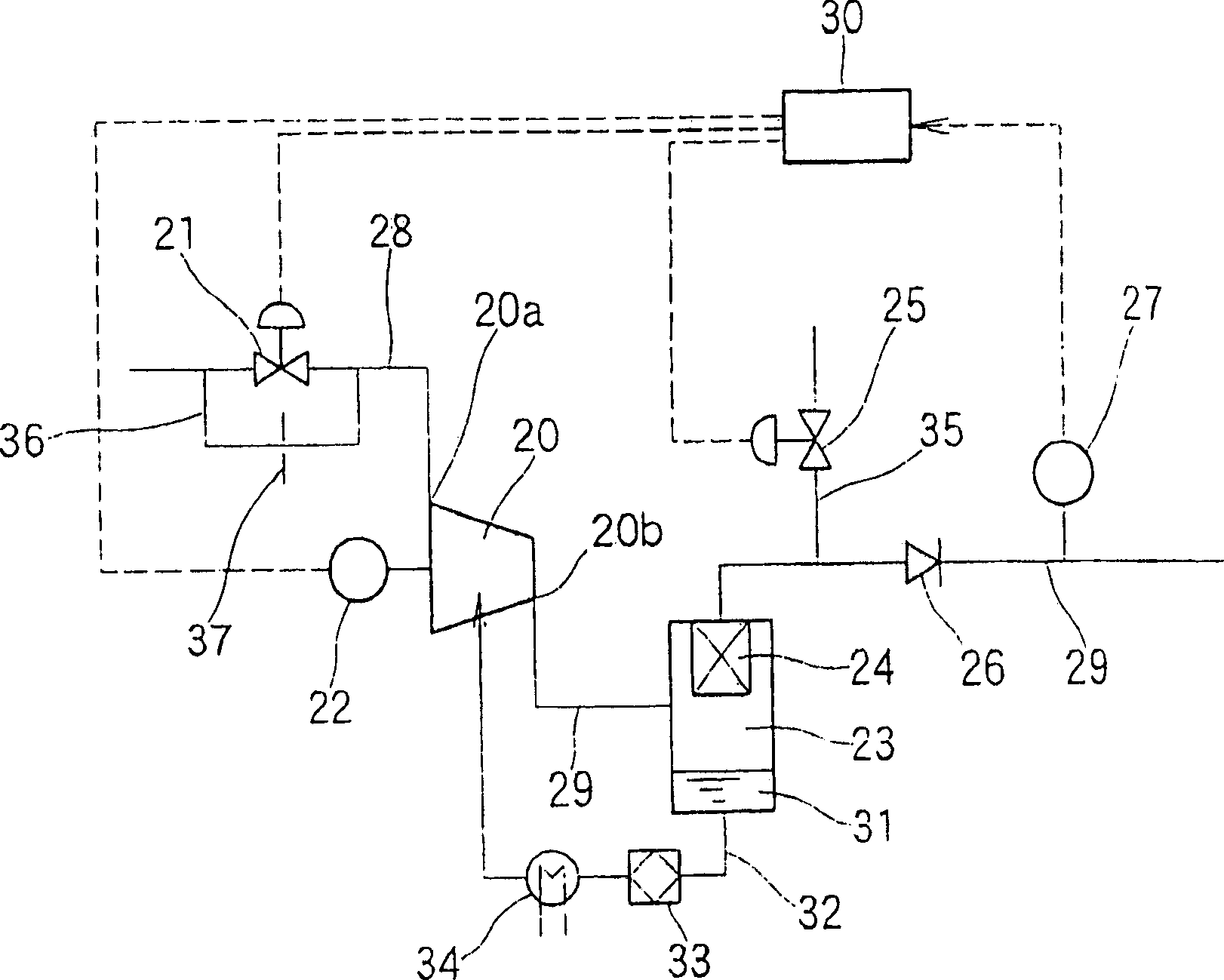

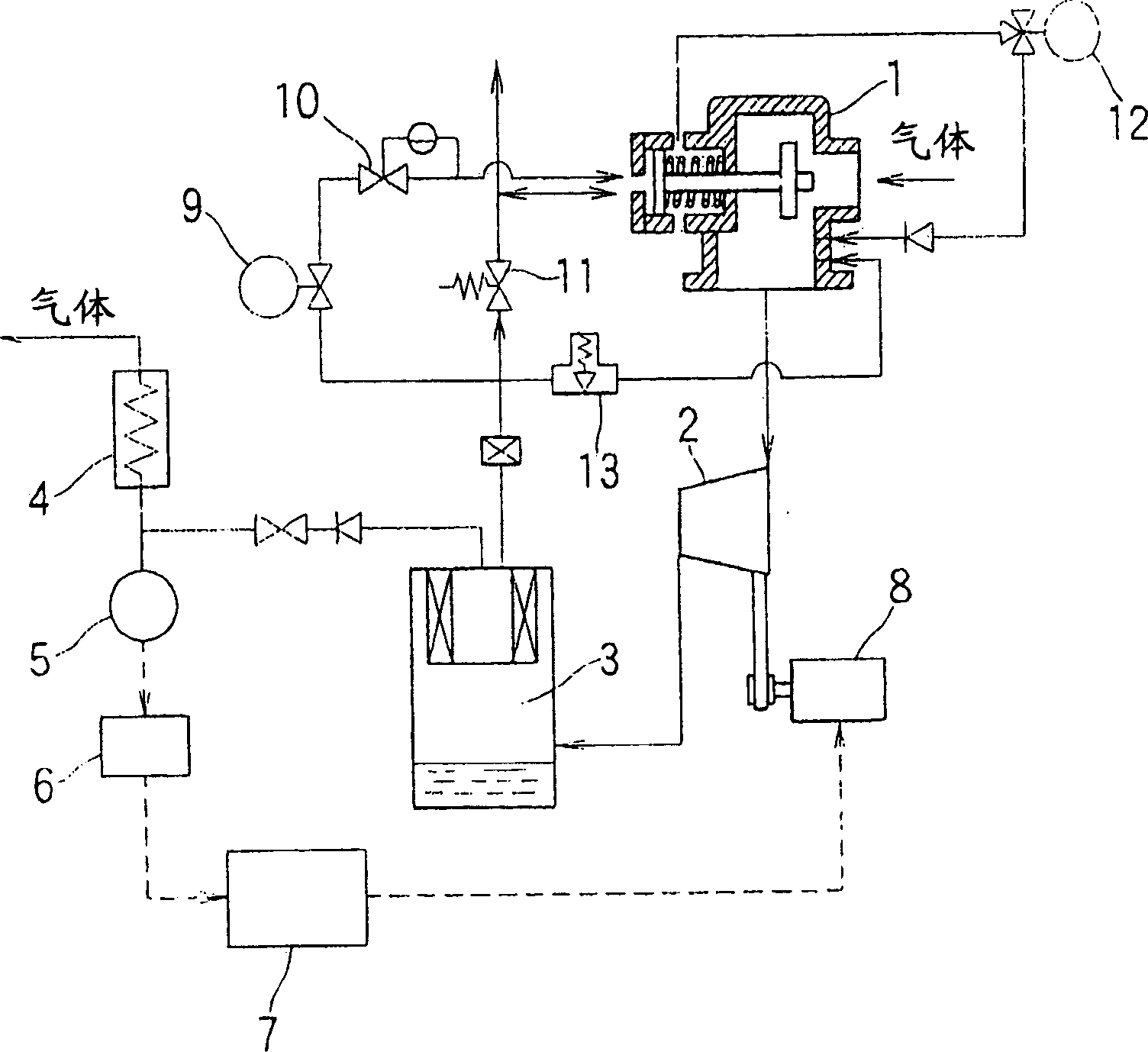

[0018] First refer to figure 1 The configuration of the compressor according to the embodiment of the present invention will be described. figure 1 It is a system diagram of the compressor according to the embodiment of the present invention, and more specifically, it is a system diagram when the present invention is applied to an oil-cooled compressor. Such an oil-cooled compressor (hereinafter referred to as a compressor) includes a compressor main body 20 having a structure in which a pair of male and female screw rotors (not shown) engage and are rotatably accommodated inside a rotor housing.

[0019] A suction flow path 28 is connected to the suction port 20a of the compressor main body 20, and a discharge flow path 29 is connected to the discharge port 20b. Also, one of the aforementioned pair of male and female screw rotors (usually a male rotor) constituting the compressor main body 20 is connected to a motor 22 .

[0020] By rotating the screw rotor with the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com