Eccentric drive mechanism for volumetric pumps or motors

A technology of eccentric drive and drive mechanism, which is applied in the direction of machines/engines, liquid variable displacement machines, pumps, etc., which can solve the problems of not allowing the formation of sufficient supporting lubricant film, etc., and achieve the effect of reliable sliding lubrication and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

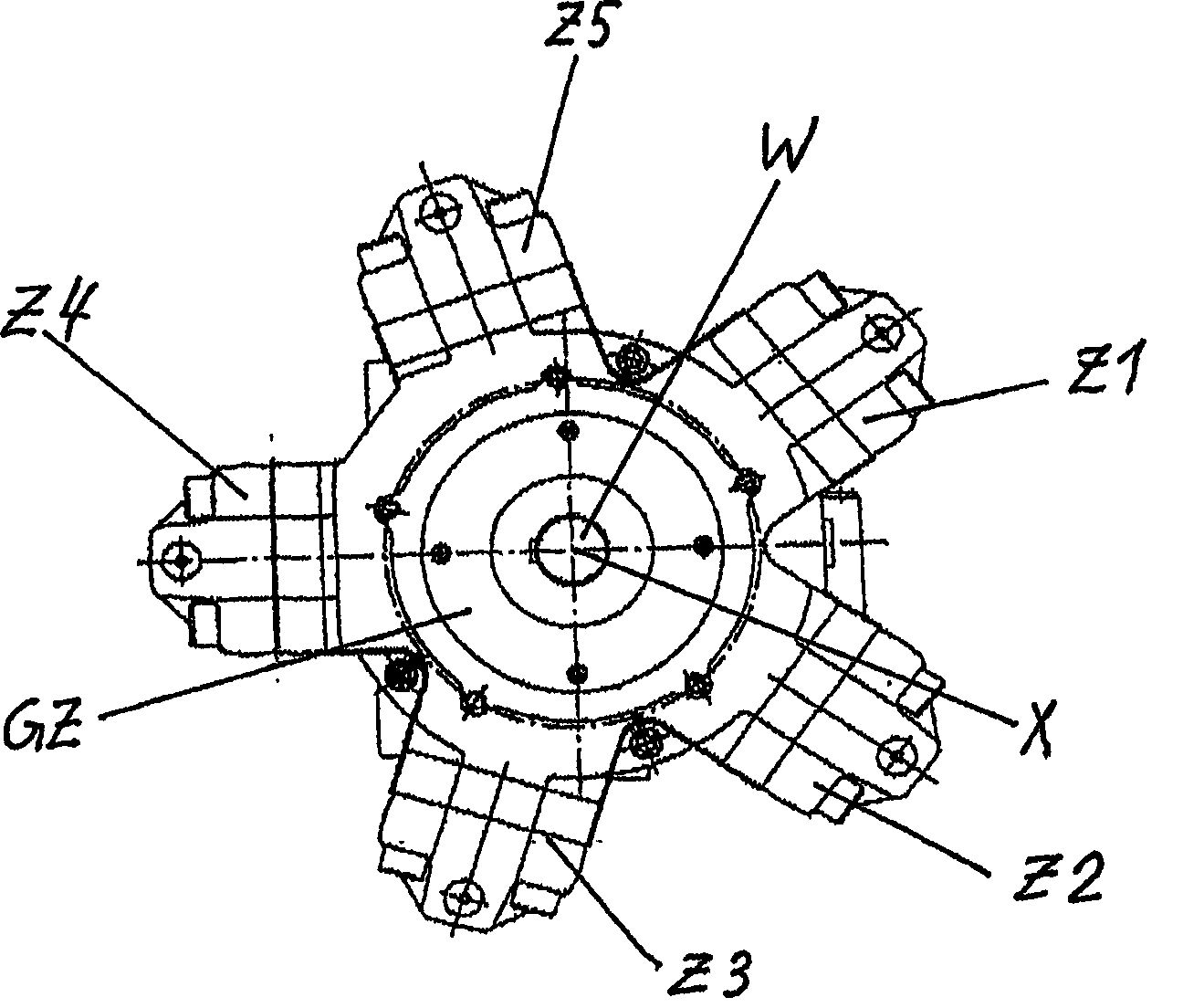

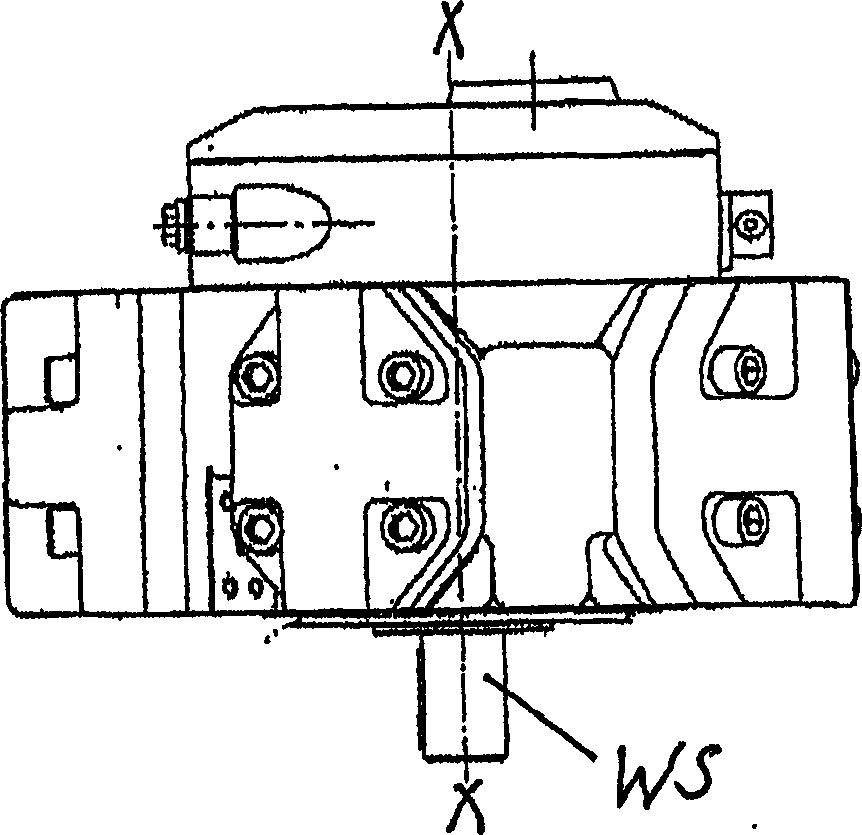

[0013] figure 1 and 2 The radial piston machine is a five-cylinder pump having cylinder-piston units (Z1) to (Z5) driven by a shaft (W) coaxially distributed with the axis (X-X) of the shaft (W) ground and evenly distributed on its periphery. An eccentric drive, not shown in detail, is located in the central housing (GZ). The drive torque is introduced via a stub shaft (WS) from a not shown motor.

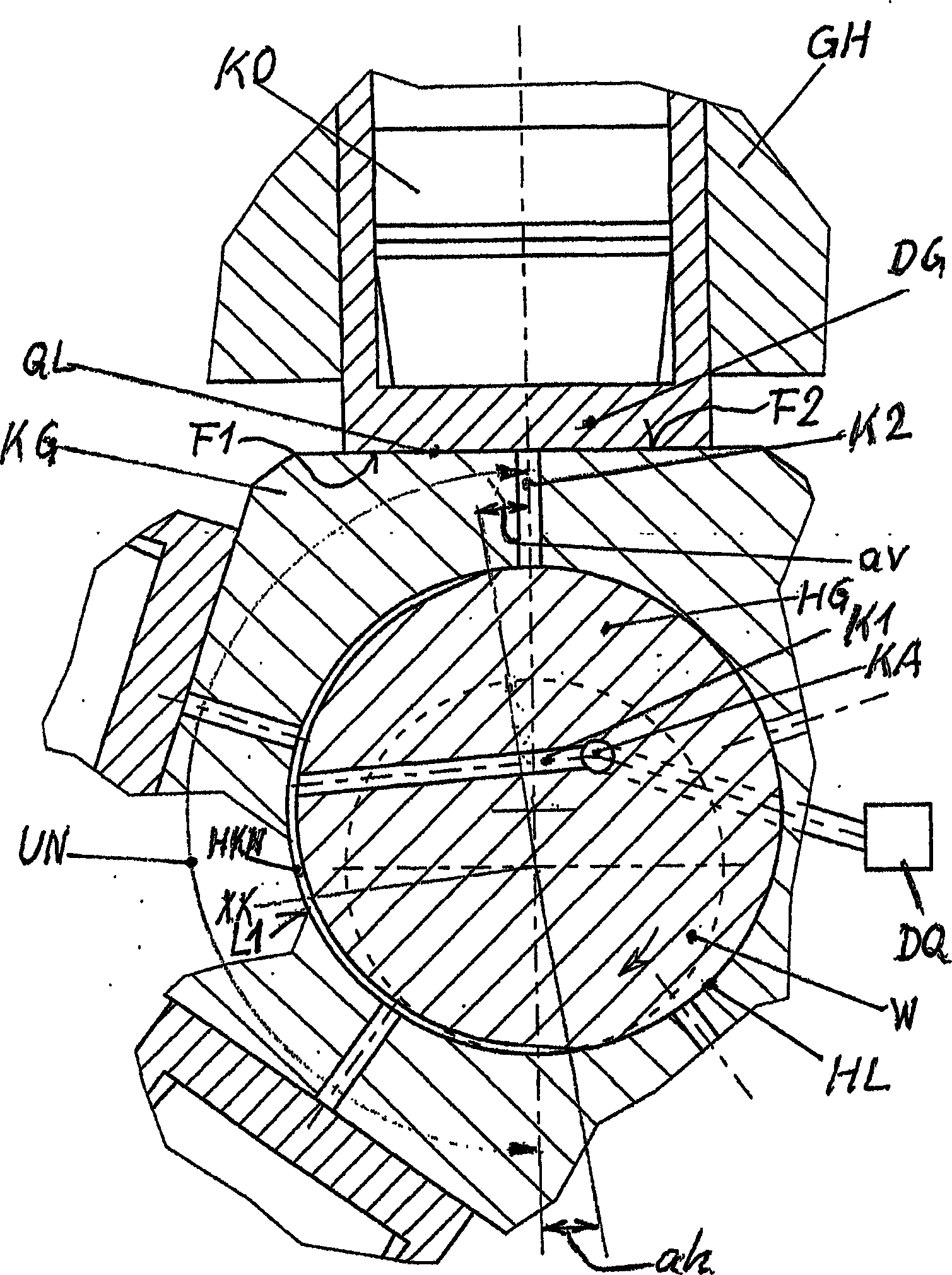

[0014] image 3 and 4 The eccentric drive mechanism shown in includes a stroke member (HG) rotatably fixedly connected to a shaft (W) and having an eccentric stroke bearing (HL) relative to the axis (XX) of the shaft. The stroke bearing (HL) connects the stroke member (HG) to a coupling member (KG) which does not take part in the rotational movement and which in turn is connected via a radial bearing (QL) to a piston-cylinder On a pressure member of the drive mechanism of the unit's oscillating delivery. In a preferred embodiment of the invention, the stroke member is a simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com