Device for pressing on a book casing

A technology of book case and heart, which is applied in the direction of book binding, book case loading, compound continuous process of book processing, etc., and can solve problems such as movement and uncontrollable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

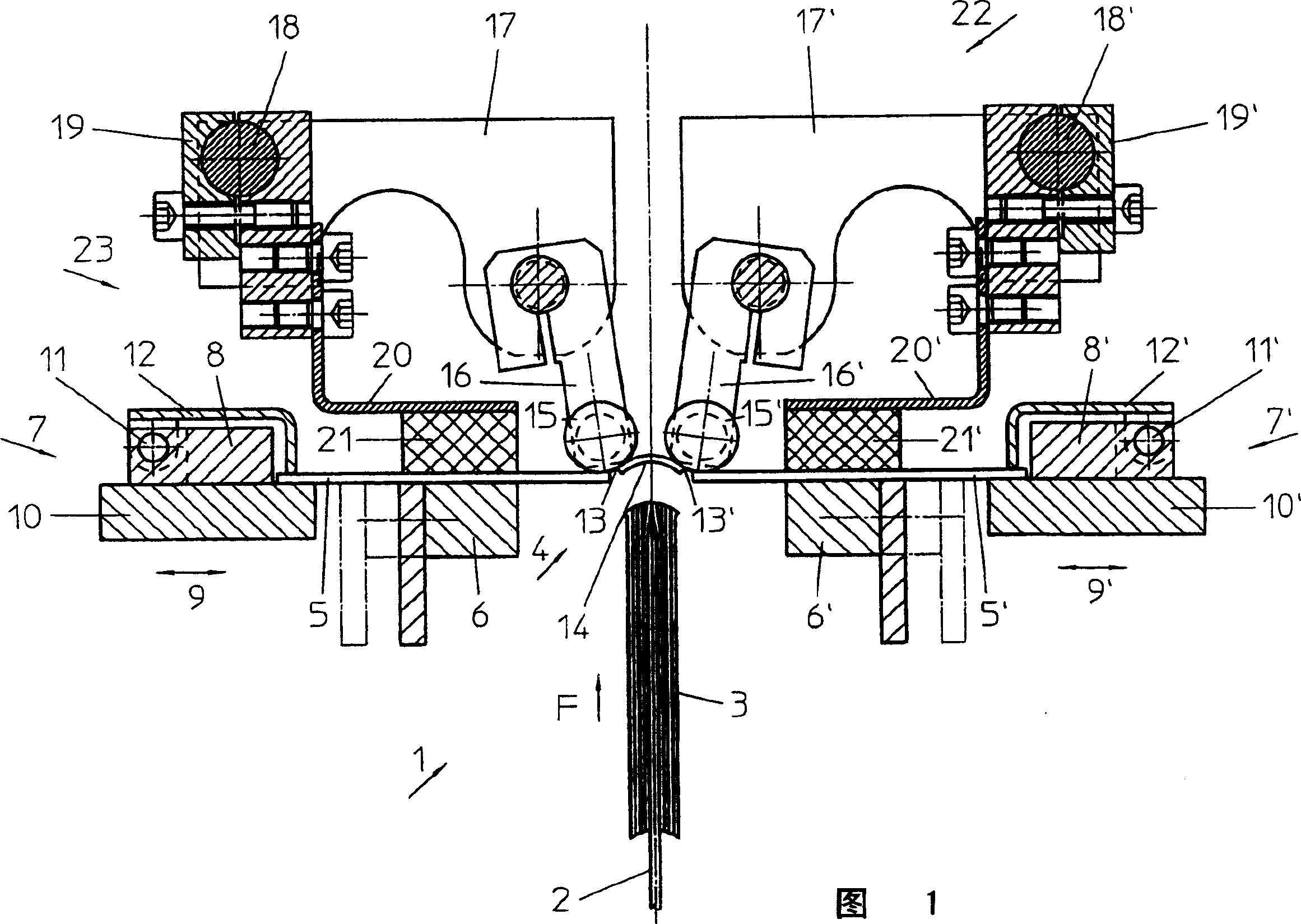

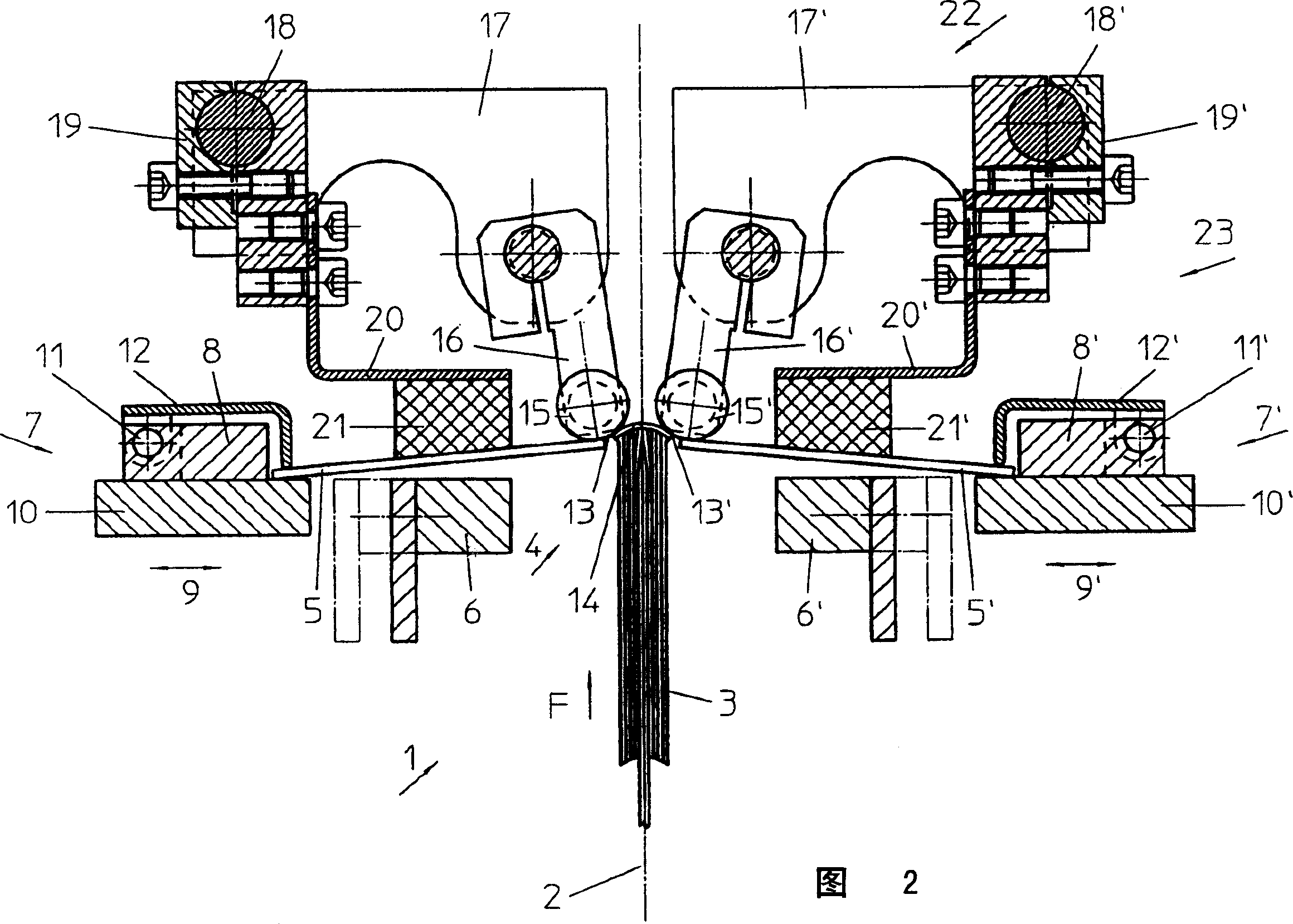

[0015] A vertical transport mechanism section 1 of a transport mechanism at the wiper station of a book block sealing machine is schematically shown in FIGS. 1 and 2 (see also EP 1 072 436 A1). Here FIG. 1 shows the exit position of an upwardly moving saddle 2 of the transport mechanism, next to which a book block 3 suspended on the saddle 2 hits the inside of a bookcase 4. Laterally, this bookcase is fed to the scraping point transversely to the movement F of the saddle plate 2 . The bookcase 4 rests on a support plane or sliding plane formed by two support slats 6, 6' with a book cover 5, 5' and laterally in a guide defined by two guide elements 7, 7'. Inside guide, this guide is used to make the book case 4 input and align. The lateral guide elements 7 , 7 ′ can be adjusted to different sizes and thicknesses of a book case 4 . Likewise, the support strips 6, 6' of the sliding plane can also be adjusted to the size of the book case 4, as indicated by the dotted lines.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com