Automatic high-cleanness sweeper

A cleaner and high-cleaning technology, applied in the direction of cleaning devices, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of material dropping along the belt and broken cutter heads, etc., and achieve good cleaning effect and convenient installation and maintenance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

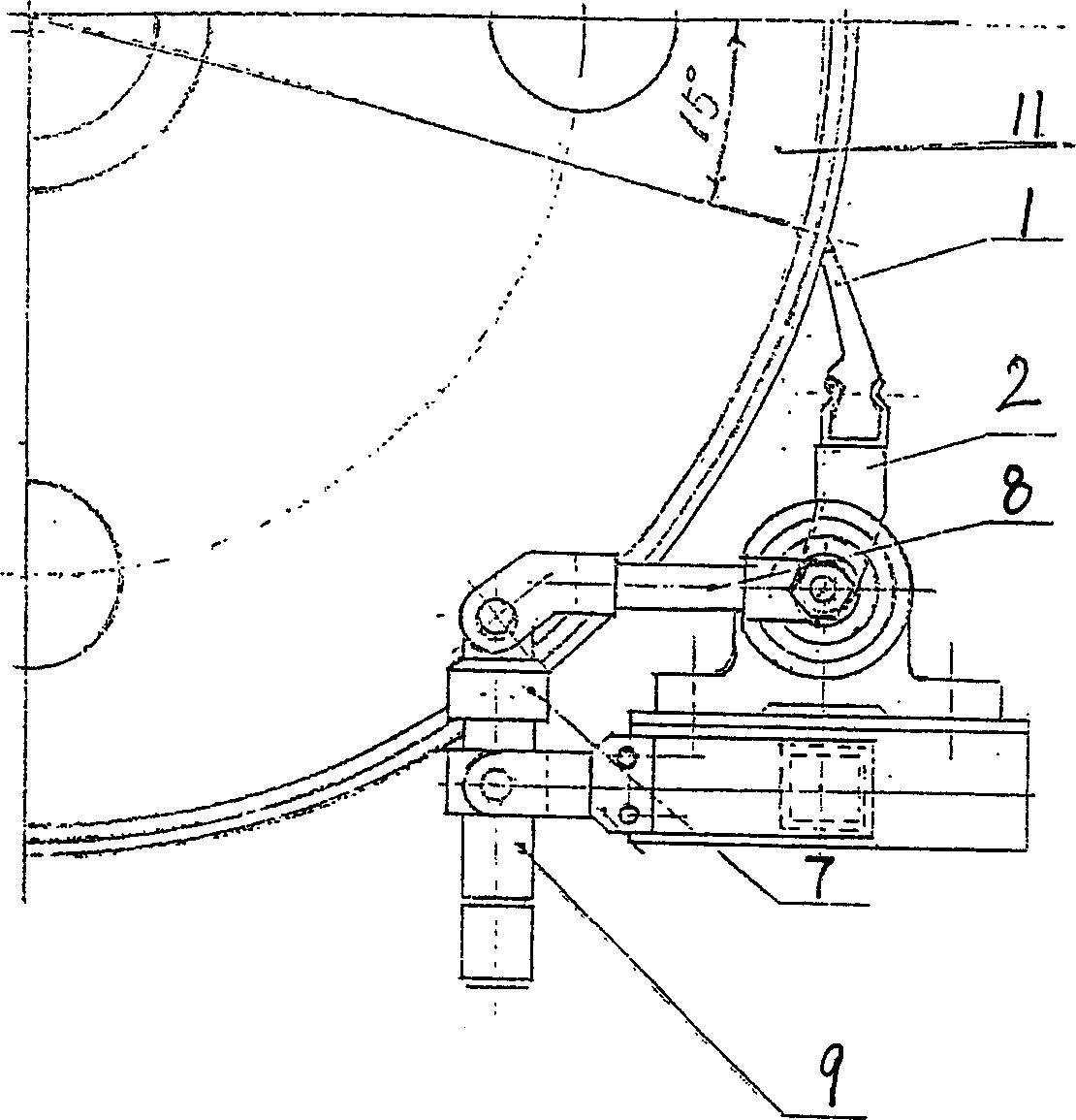

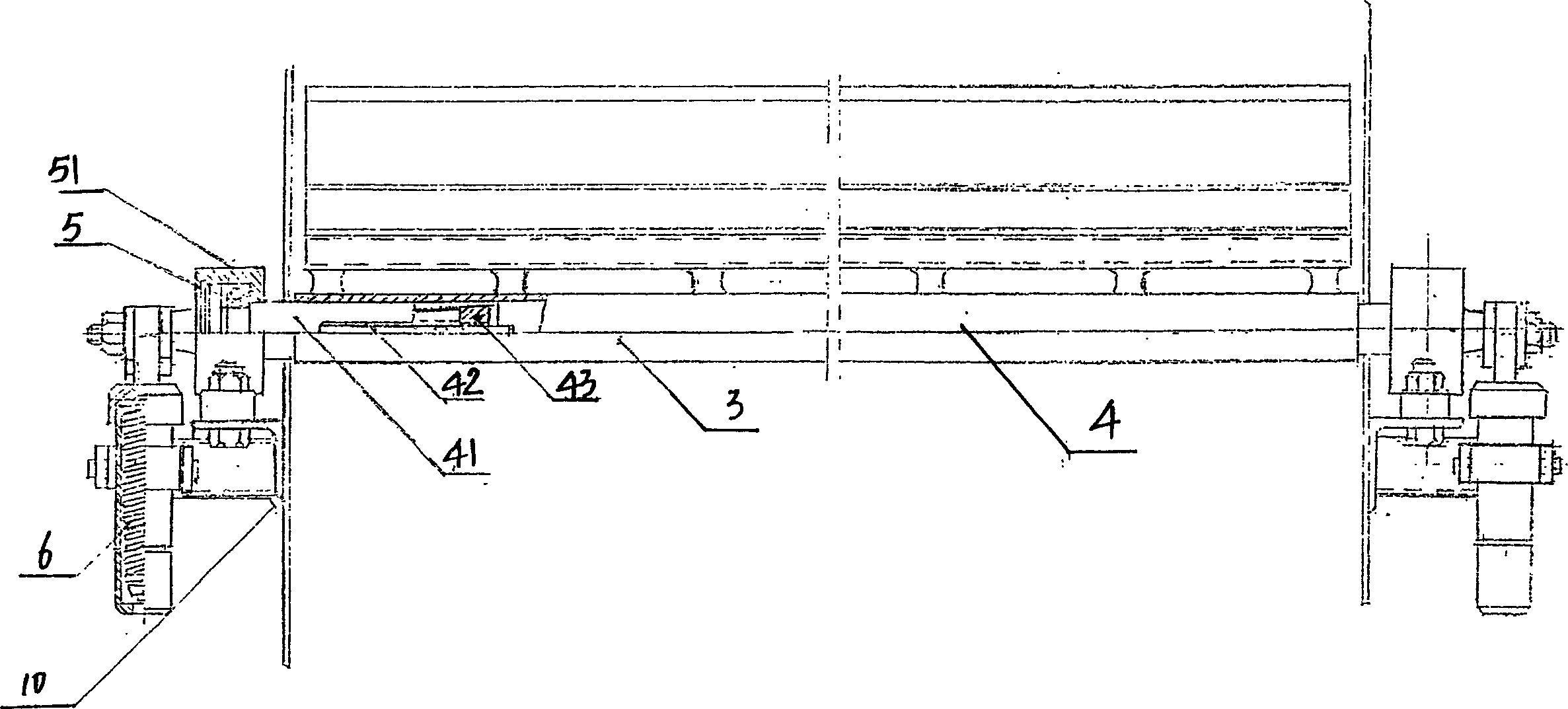

[0021] An automatic high-cleanness cleaner according to the present invention, the knife edge plate 1 is used to install the cutter head, and the cutter head is in close contact with the conveyor belt 11; the knife edge plate 1 is arranged on the beam 2; the beam 2 is fixed on the main shaft 3, The main main shaft 3 is set on the main main shaft 4 and can swing with the main main shaft 4; both ends of the main main shaft 4 are supported by the bearings 5 arranged in the bearing housing 51; the spring 6 arranged in the spring cylinder 9 passes through The extension spring screw rod 7 is connected with one end of the extension spring chain rod 8; the other end of the extension spring chain rod 8 is connected with the master shaft 4 in charge and can make the master shaft 4 in charge swing; the spring cylinder 9 and the bearing seat 51 are fixed on the bracket 10 superior.

[0022] In order to meet different occasions or hoppers with different widths and ensure convenient insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com