Dual Wavelength light-emitting source for chromatography printing register sensor

A technology of chromatic printing and sensors, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of plate instability and plate sensors that cannot be arbitrarily flexible, so as to achieve strong practicability and improve the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

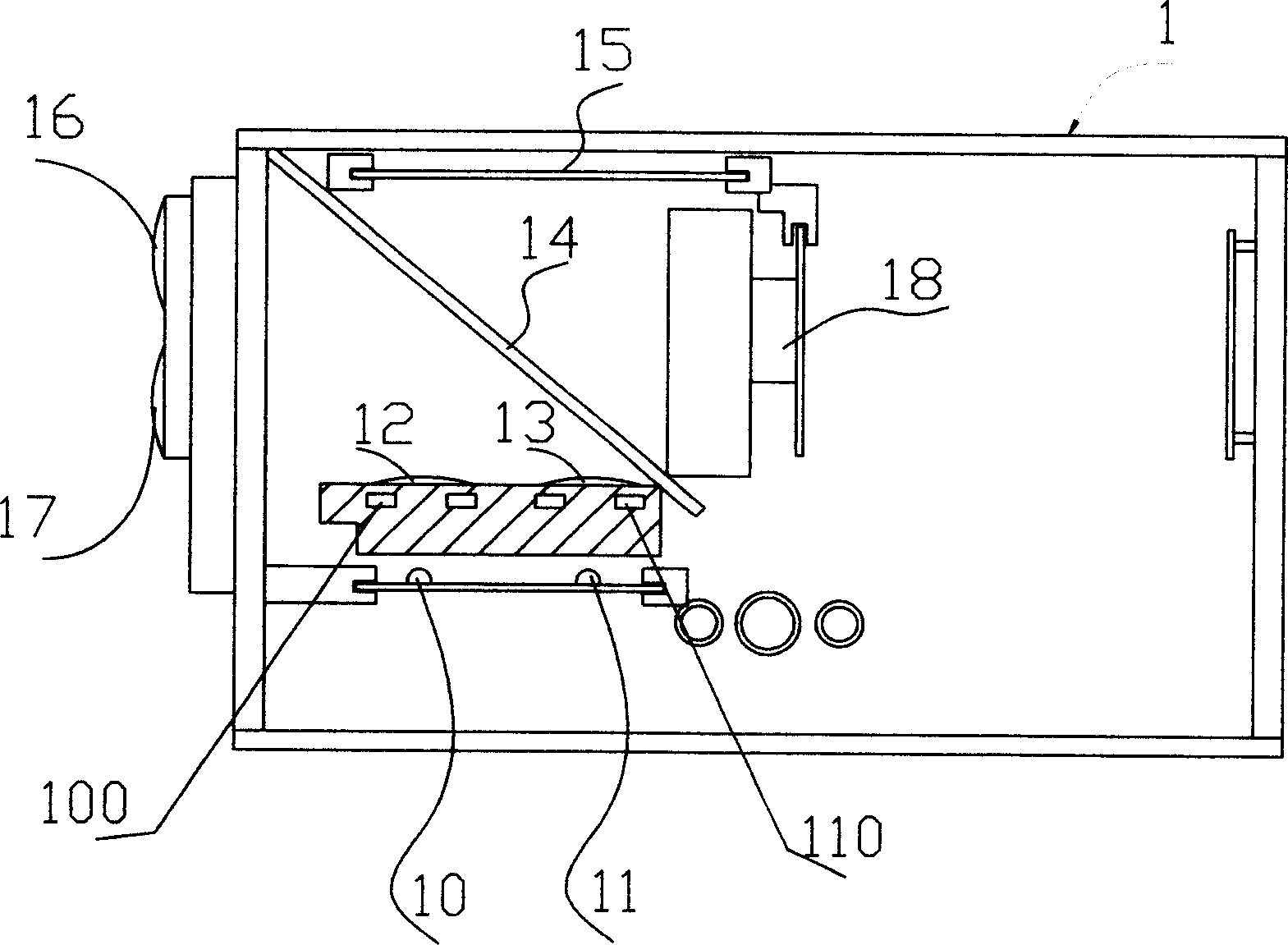

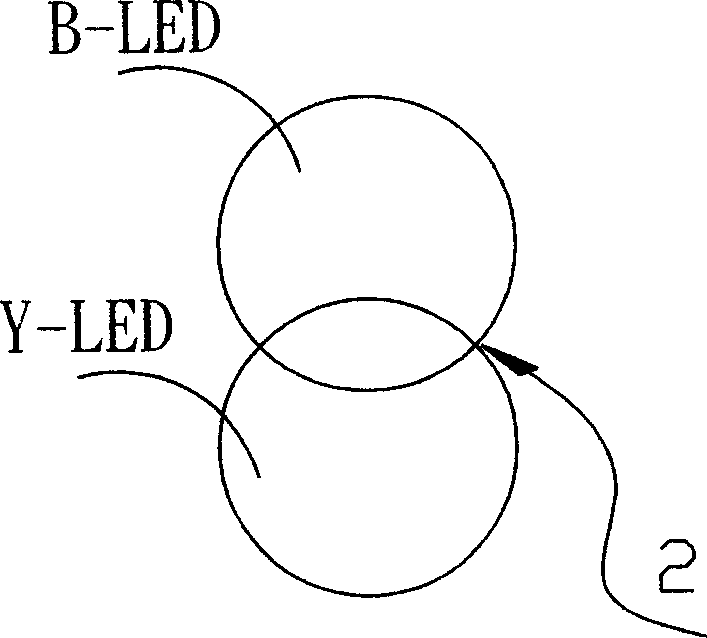

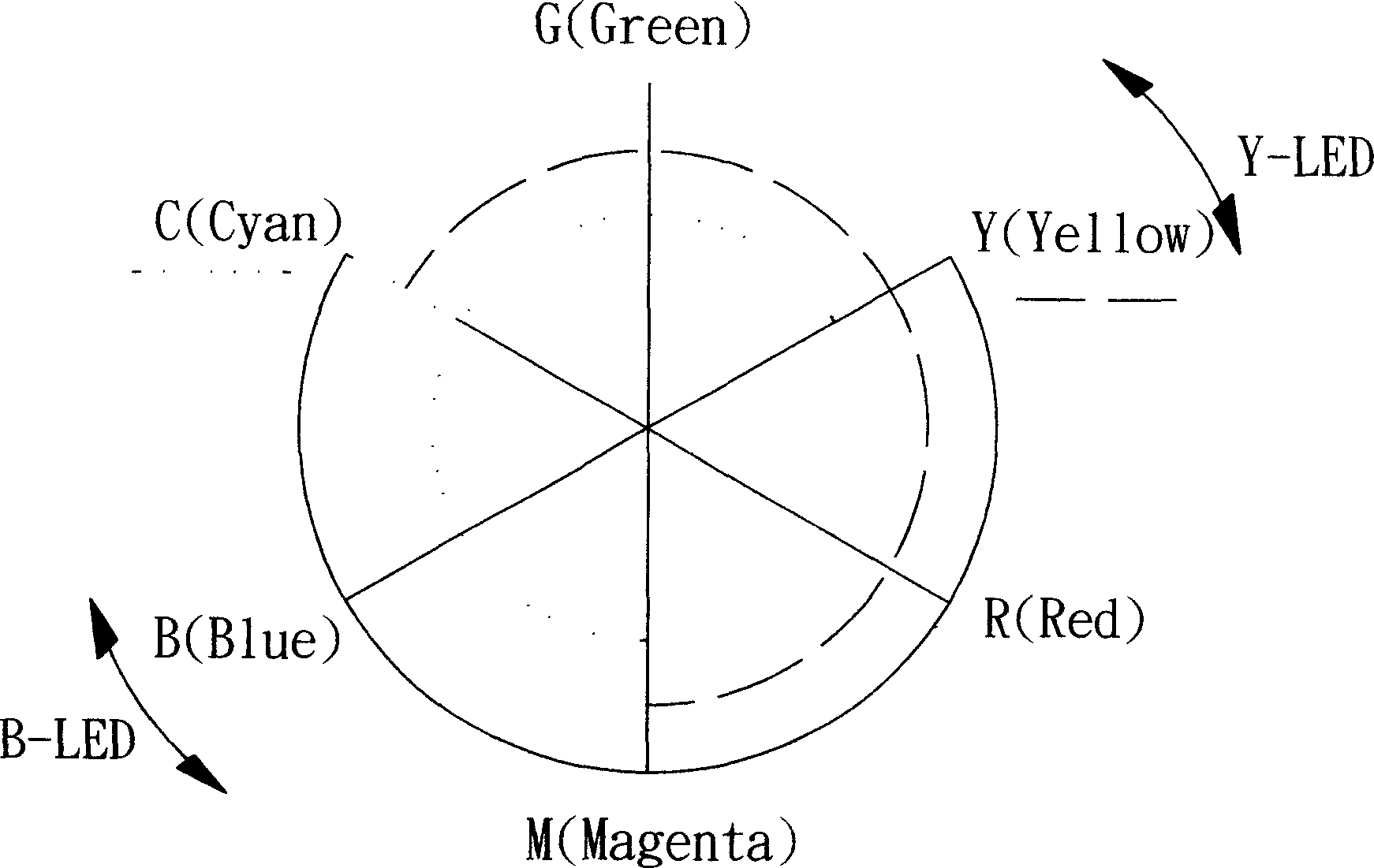

[0014] as attached figure 1 to attach Figure 4 As shown, the plate alignment sensor 1 of the present invention is mainly composed of a pair of dual light source LED lamps 10, 11 with a distance of 20 mm and their associated control circuits. The first dual light source LED lamp 10 and the second dual light source LED lamp 11. An aperture pad 100, 110 is arranged at the front end to prevent the two groups of light from interfering with each other. Convex lenses 12, 13 are respectively arranged in front of the aperture pad 100, 110, and a 45-degree angle is placed in the central area inside the plate-aligning sensor 1. A single beam splitter 14 can reflect the dual light sources 2 emitted by the first and second dual light source LED lamps 10, 11 to the outer lenses 16, 17 of the plate sensor 1 through the beam splitter 14, and the pair A light-absorbing sheet 15 is provided on the upper edge of the plate sensor 1 to prevent the dual light sources 2 emitted by the first and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com