Fabric guide plate and rise plate linkage mechanism

A technology of linkage mechanism and guide plate, which is applied in knitting, weft knitting, textile and papermaking, etc., can solve the problems of high production cost, many parts and components, complicated mechanism, etc., and achieves low manufacturing cost, reliable work, and guarantees normal work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

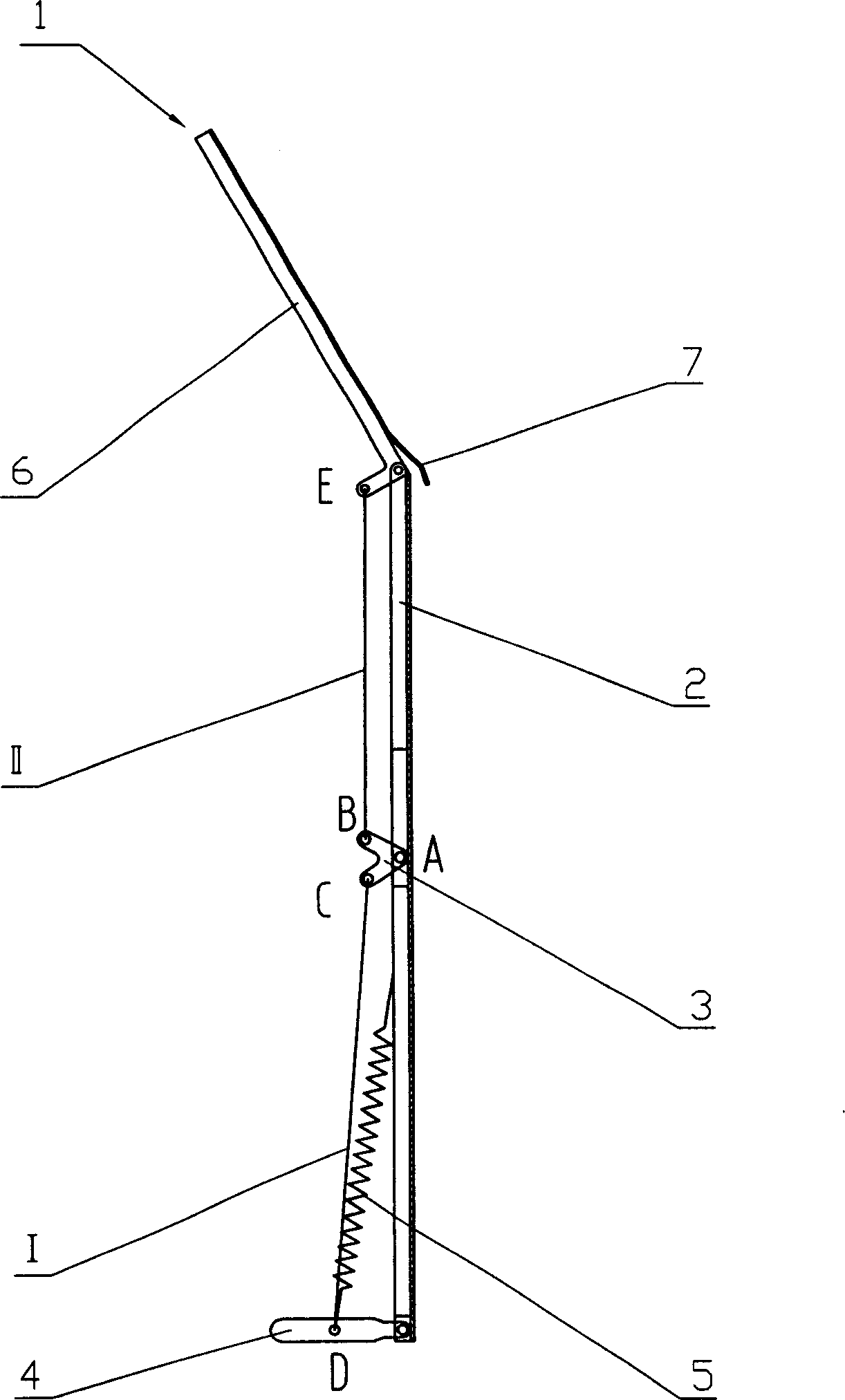

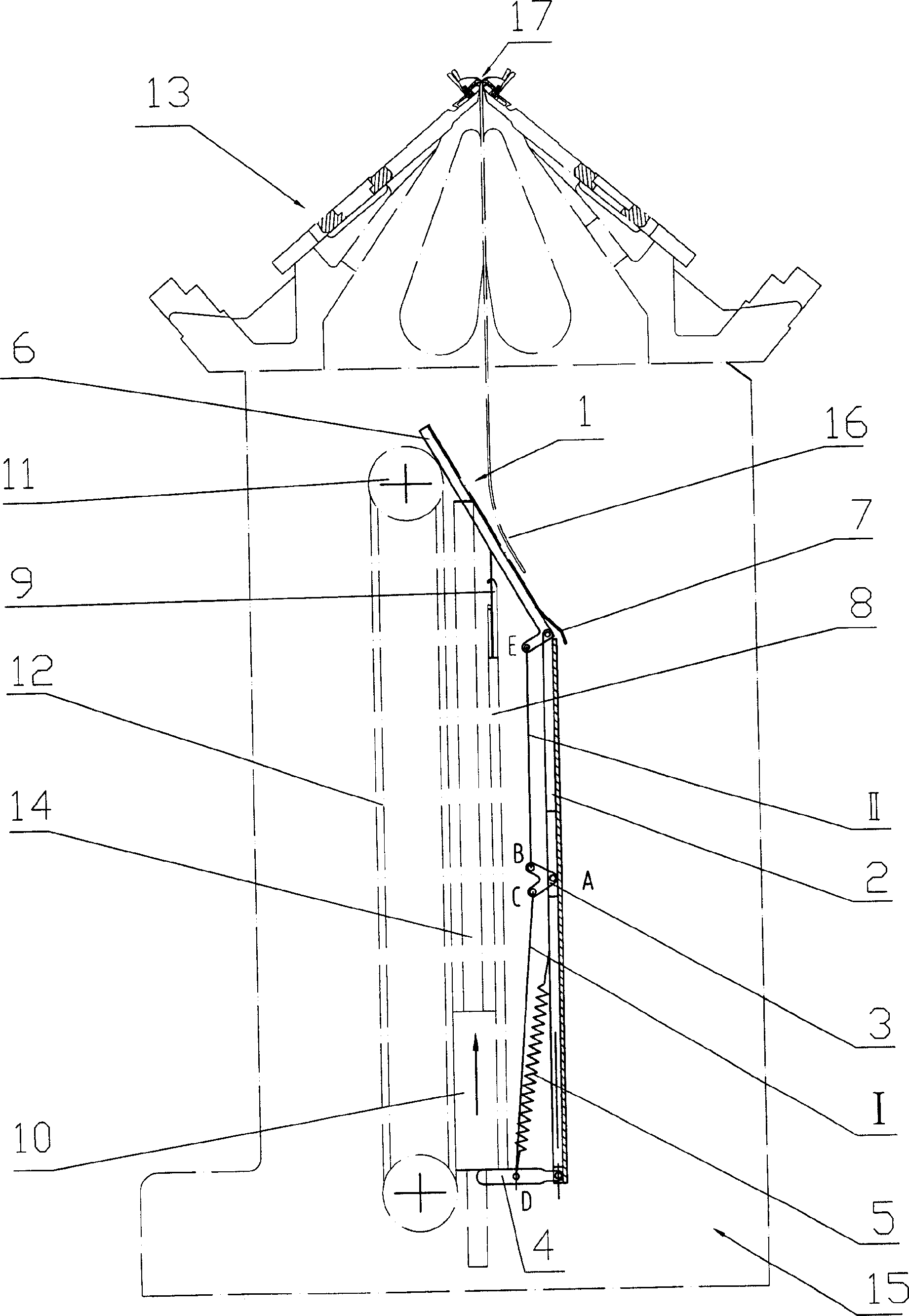

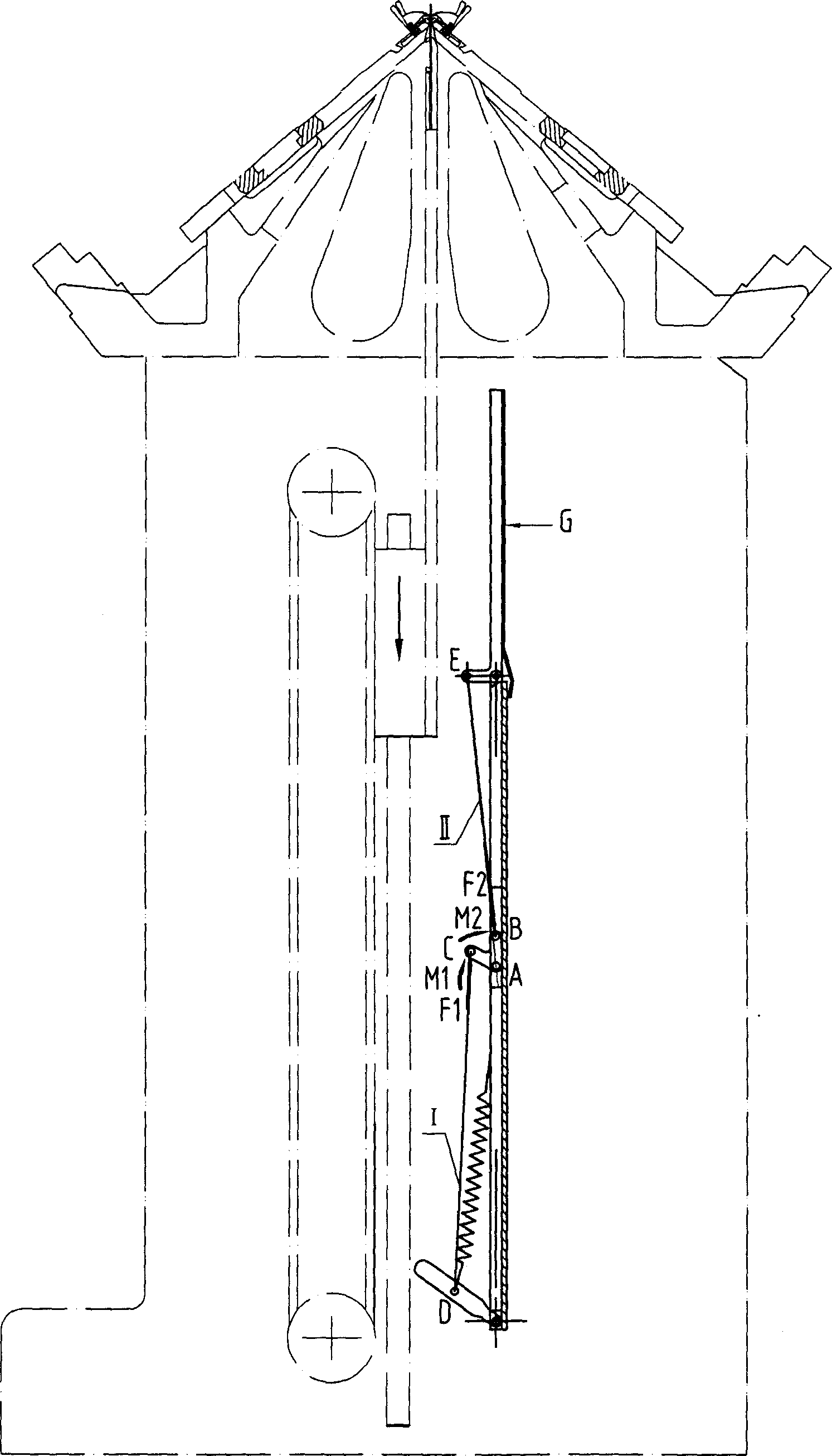

[0014] See figure 1 , The mechanism of the present invention is made up of guide plate 1, guard plate 2, support plate 3, control rod 4, pull rod I, pull rod II and extension spring 5. Wherein the guard plate 2 is installed in the cabinet 15 on the lower side of the flat knitting machine 13, the guard plate 2 is placed on the front side of the needle lifting plate 8, and is located at the position where the sliding hinge seat 10 can be crimped, see figure 2 or image 3 . The upper end of guard plate 2 is hinged with the lower end of guide plate 1, and guide plate can be rotated around its hinge axis, and its range of rotation is from the oblique position of guide plate 1 and horizontal angle about 60 ° to the vertical position. The guide plate 1 is made up of a frame 6 and a panel 7, the panel 7 is connected to one side of the frame 6 by sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com