Deformable lens and optical pickup device including same

A technology for deformable mirrors and mirrors, which is applied in the field of optical pick-up devices and mirror shape changes, and can solve the problems of small expansion and shrinkage of piezoelectric elements and increase the shape change of mirror parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the drawings. It should be understood that the embodiments described below are only examples, and therefore do not represent any limitation on the way of implementing the present invention. It should also be understood that in the drawings, the size and thickness of each component, the amount of shape change when the shape changes, etc., are exaggerated for the purpose of easy understanding, so these dimensions are not the same as the actual observed size. same.

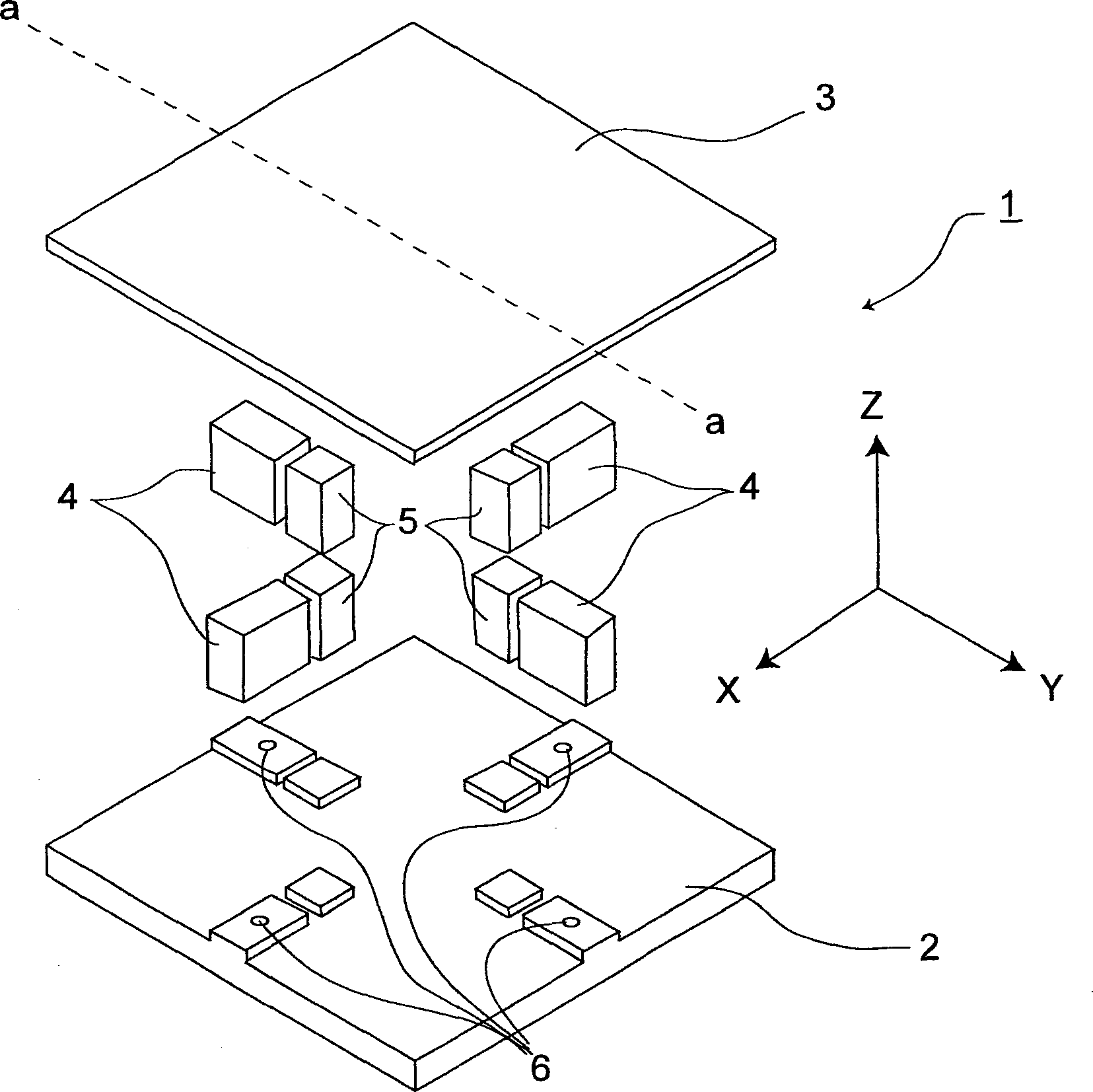

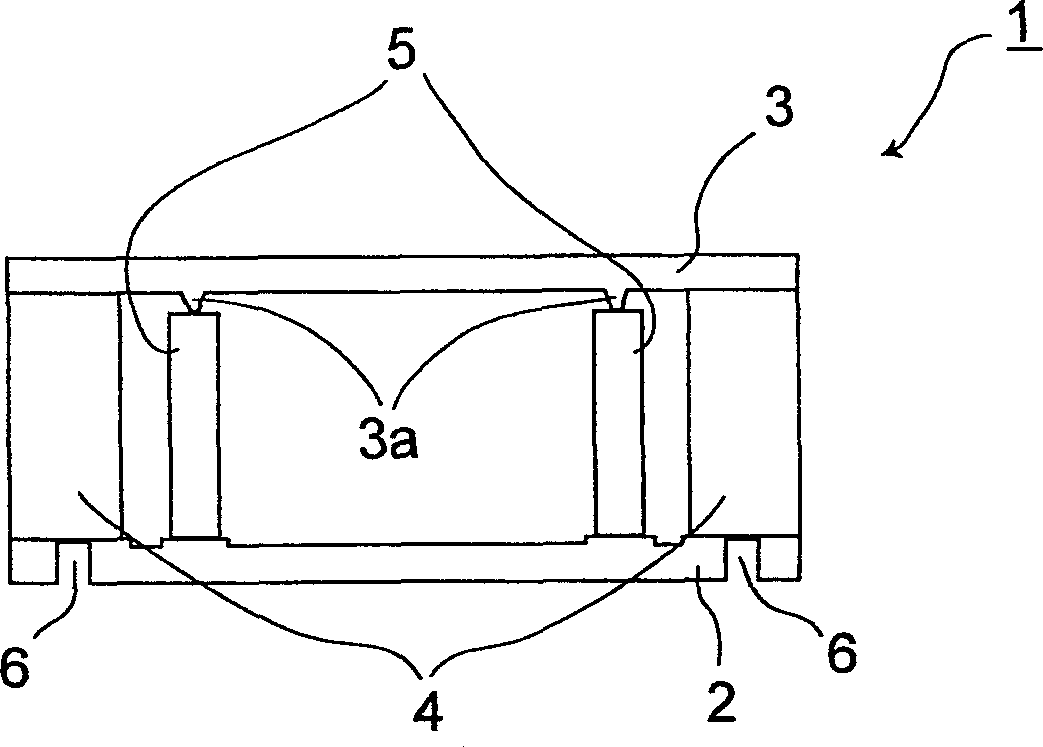

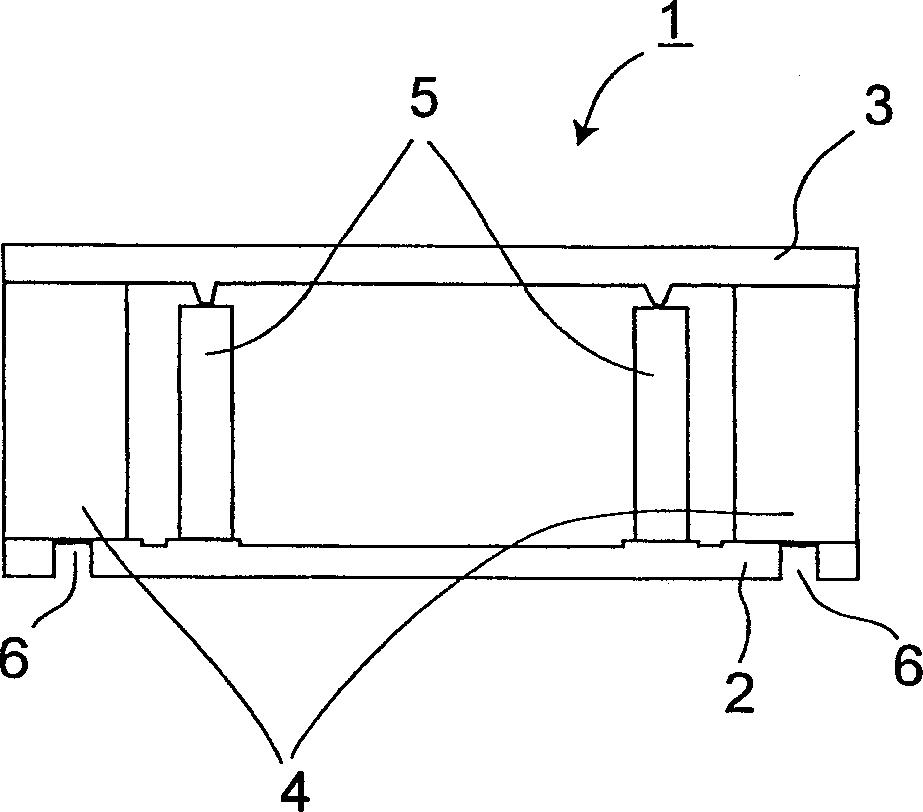

[0032] Figure 1A The schematic diagram of shows the structure of the deformable mirror as an embodiment of the present invention, which shows its components in an exploded perspective view. Figure 1B is along Figure 1A A cross-sectional view cut along the line a-a in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com