Vibrating device for jet flow generating including a voice coil motor

A technology of vibrating device and vibrating piece, applied in electromechanical devices, circuits, electrical components, etc., can solve the problems of bending of the vibrating piece, loud noise, and the vibration will not transmit gas effectively, and achieve the effect of suppressing noise and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

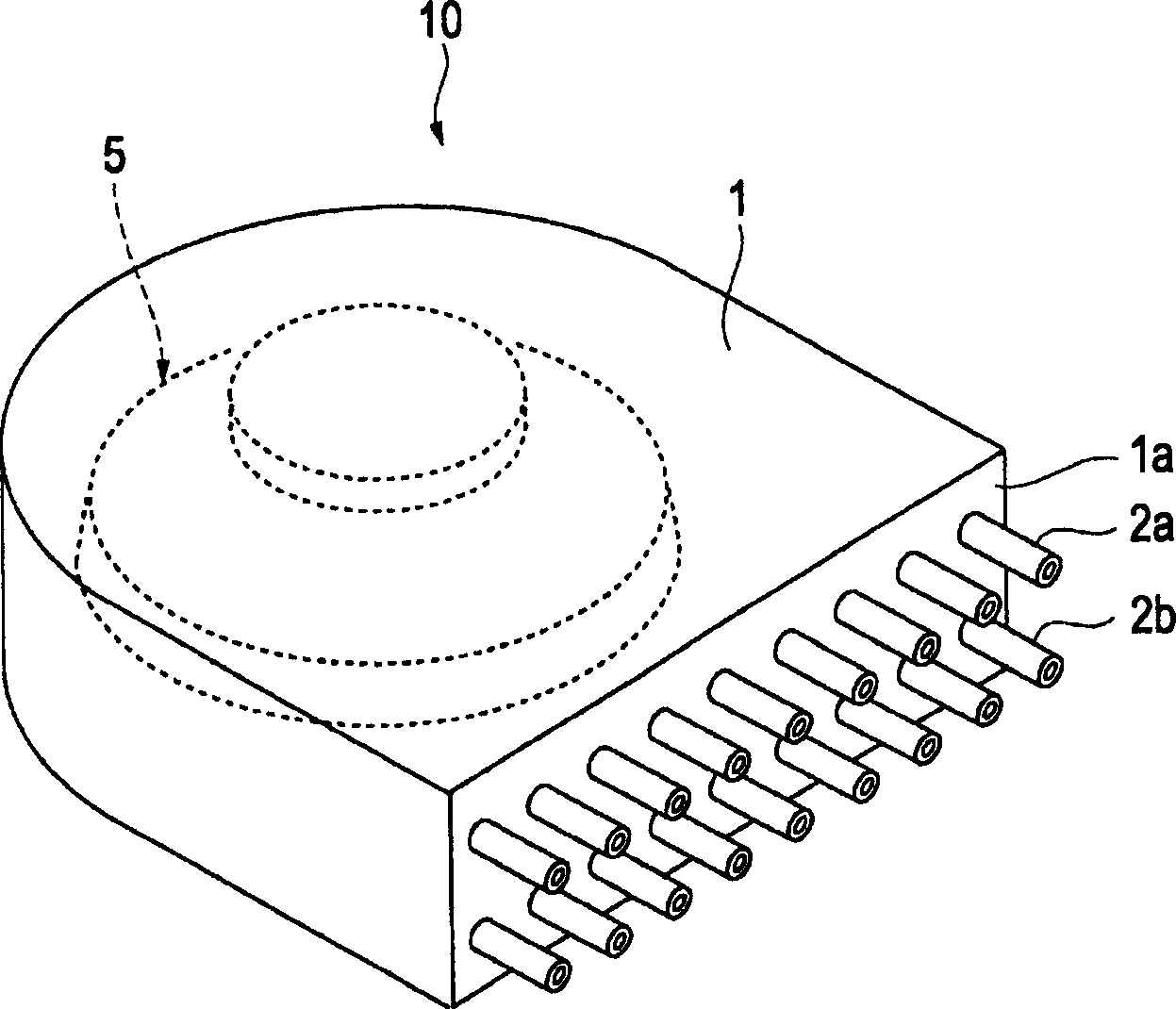

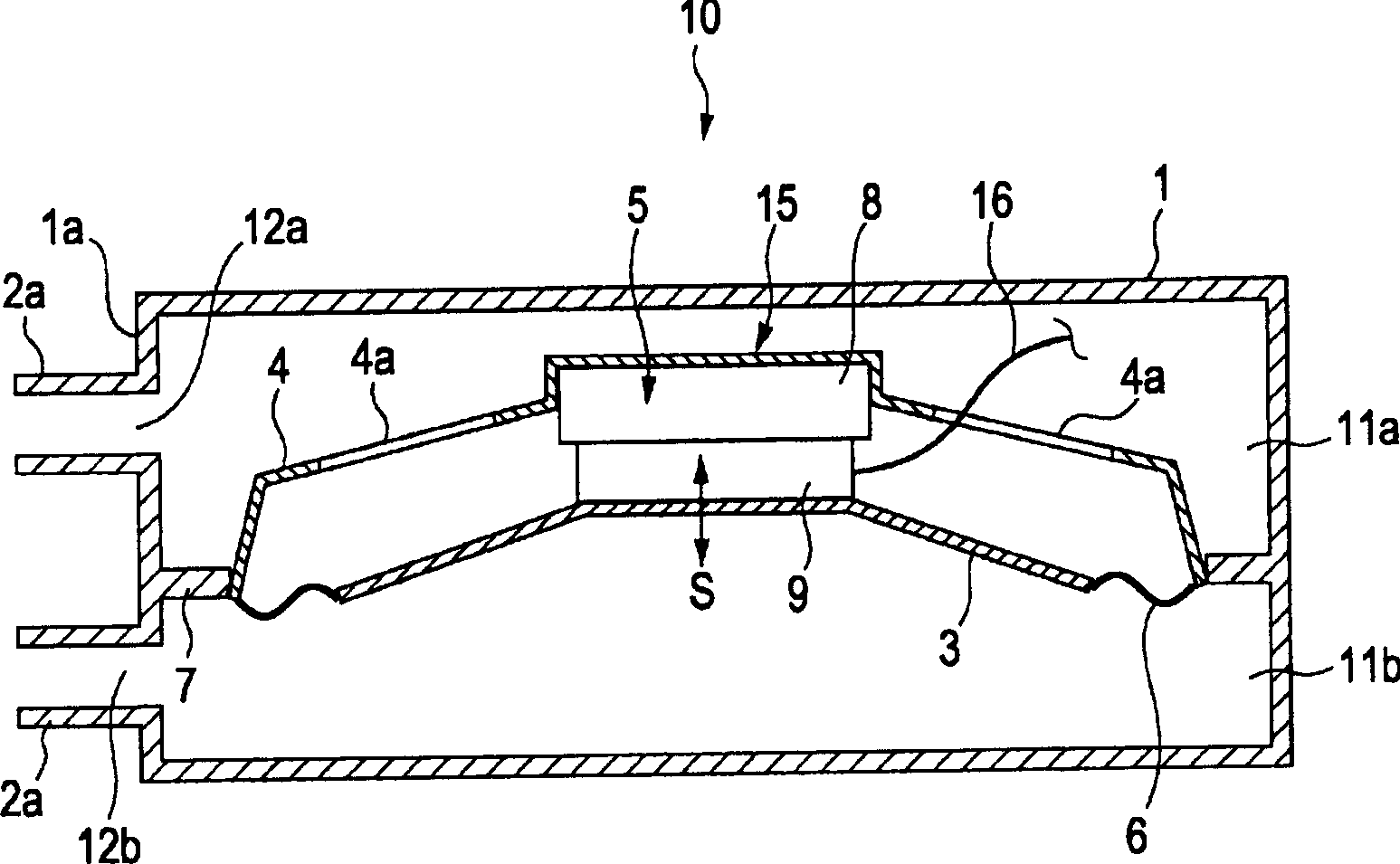

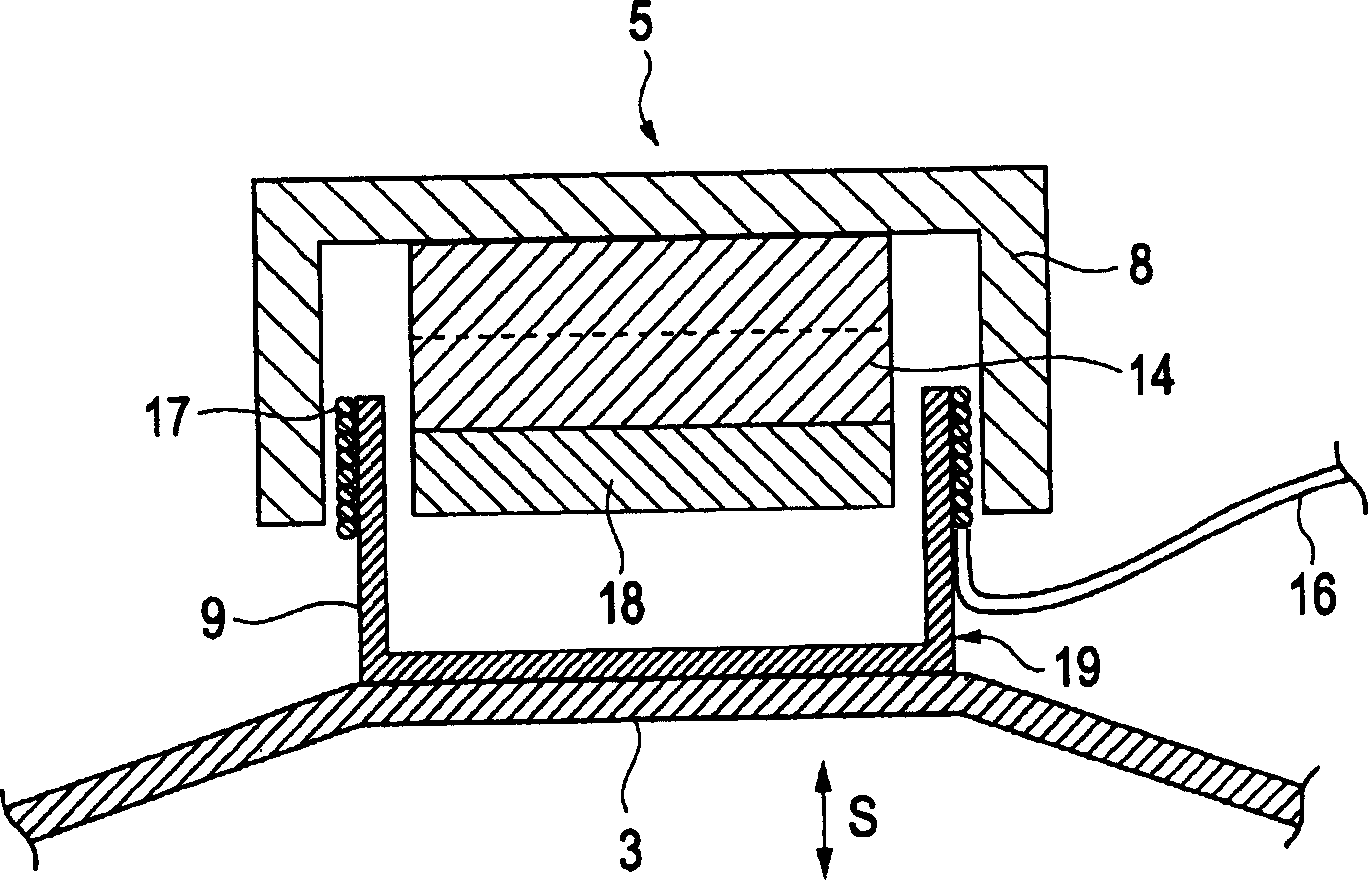

[0065] figure 1 is a perspective view of the jet flow generating device according to the first embodiment of the present invention. figure 2 for figure 1 A cross-sectional view of the jet flow generating device shown.

[0066] The jet flow generating device 10 includes a casing 1 with a circular rear part and a vibrating device 15 arranged inside the casing 1 . On the front face 1a of the cabinet 1, a plurality of rows of nozzles 2a and 2b are provided. Such as figure 2 As shown, the interior of the casing 1 is divided into an upper chamber 11a and a lower chamber 11b by the connecting piece 7 connecting the vibrating device 15 . Openings 12a and 12b are formed at positions corresponding to the nozzles 2a and 2b on the front surface 1a of the cabinet 1 where the nozzles 2a and 2b are provided, respectively. In this way, the upper chamber 11 a and the lower chamber 11 b communicate with the outside of the cabinet 1 . The upper chamber 11a and the lower chamber 11b have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com