Combined air vent valve with buffer device

A cushioning device and composite technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of safety hazards, environmental pollution, easily damaged valve components and pipeline accessories, etc., to prevent a large amount of spraying , Protect the environment from being polluted, and the effect of safety from polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

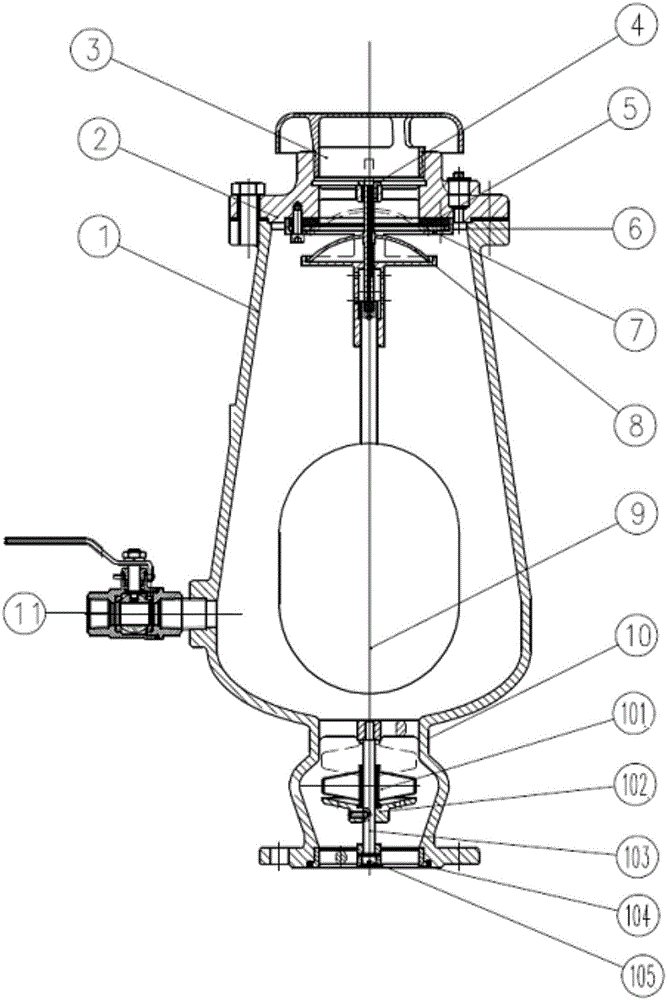

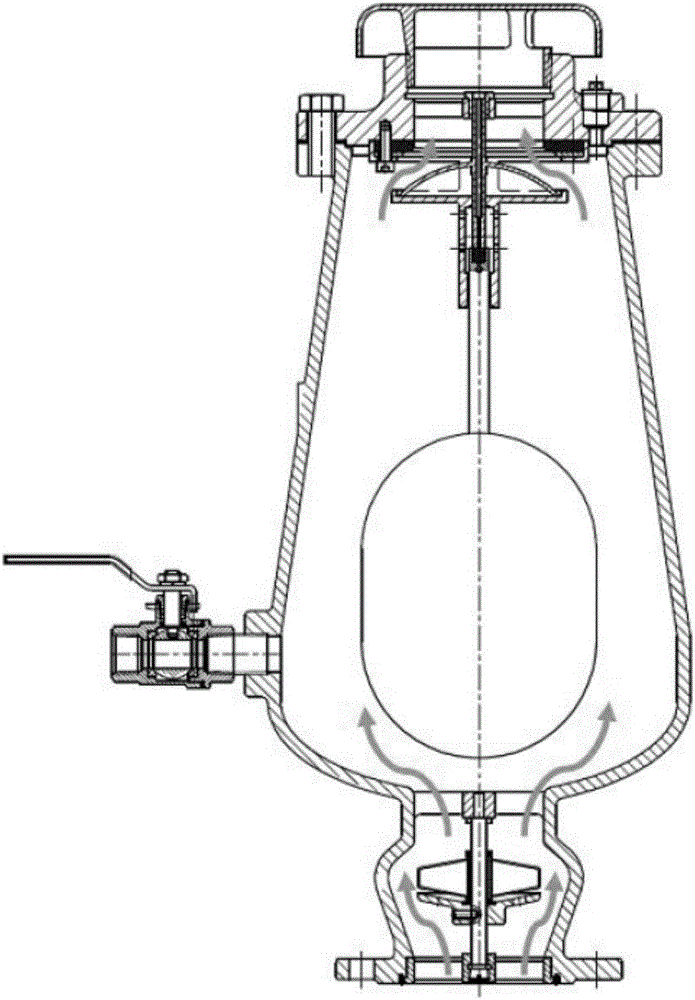

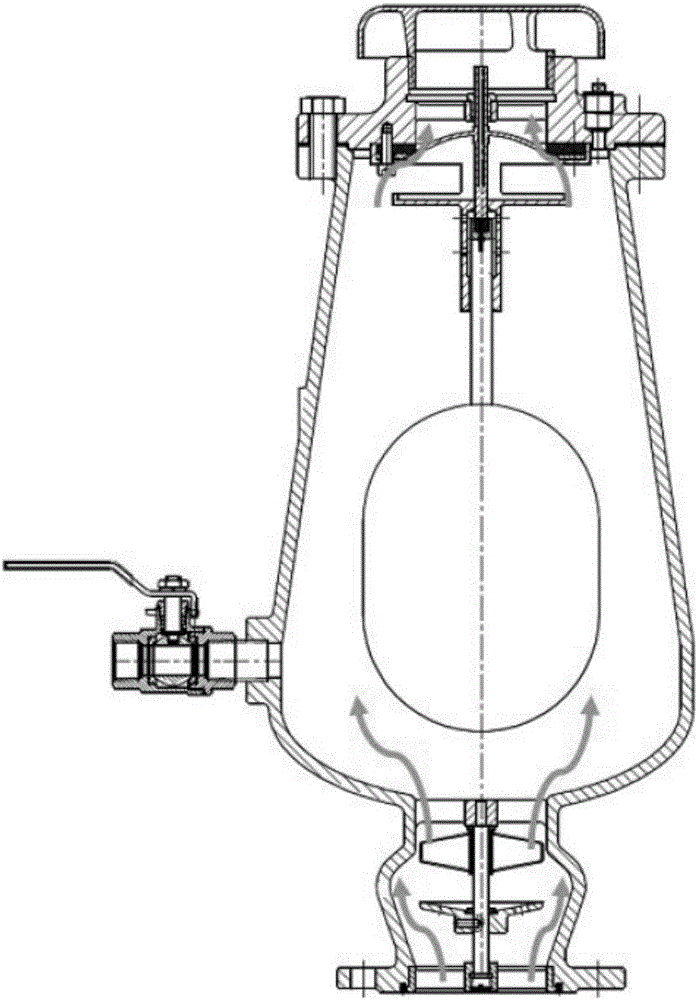

[0021] like figure 1 As shown, the exhaust valve includes valve body 1, valve cover 2, exhaust cover 3, guide sleeve 4, sealing ring 5, limit plate 6, piston frame 7, piston 8, main floating ball 9, floating ball buffer device 10. Ball valve 11; floating ball buffer device 10 includes buffer floating ball 101, buffer frame 102, sliding shaft 103, lower bracket 104, screw plug 105; valve body 1 is equipped with main floating ball 9 and seal ring on valve cover 2 5 connected, the piston 8 forms a sealing body under the hydraulic drive of the main floating ball 9; the valve cover 2 is connected to the exhaust cover 3, and the piston frame 7 is connected to the bottom and fixed on the valve body 1 with bolts; the exhaust cover 3 is screwed to the valve On the cover 2, it is used for a large amount of exhaust and suction structure; the guide sleeve 4 is used to guide the vertical movement of the piston 8 and is fixed on the valve cover 2; the sealing ring 5 is fixed between the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com