Method for pressing plasma in presser and device thereof

A technology of pulp floc and equipment, which is applied in the field of compacted pulp floc, can solve the problems that the volume density of the pulp in the cyclone separator fluctuates greatly, it is difficult to produce packing materials with weight deviation, and it cannot be corrected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

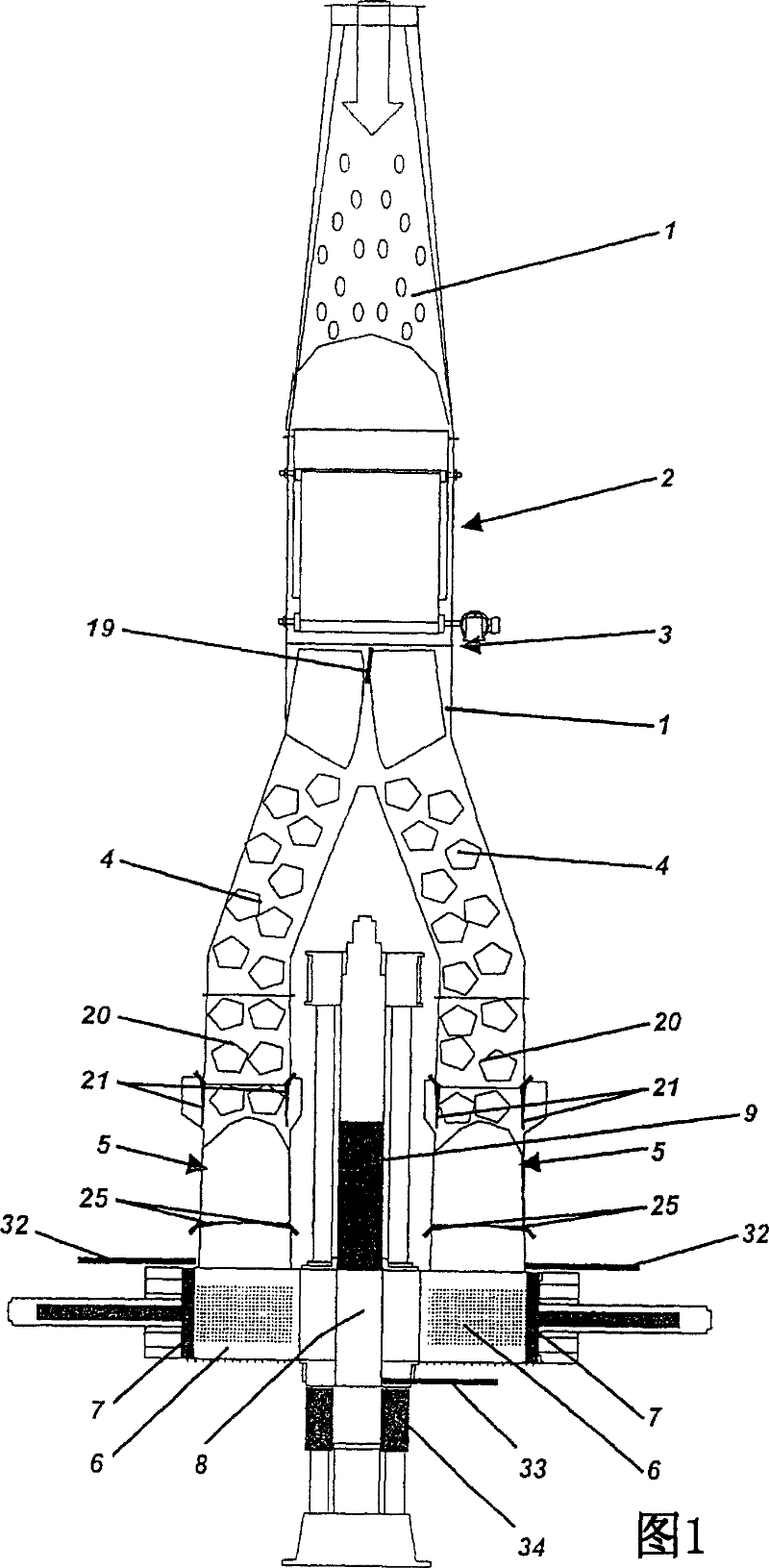

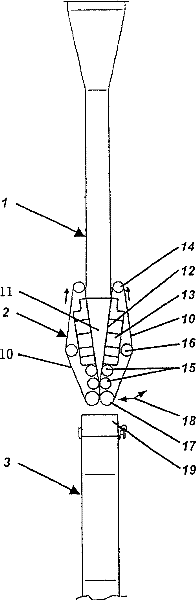

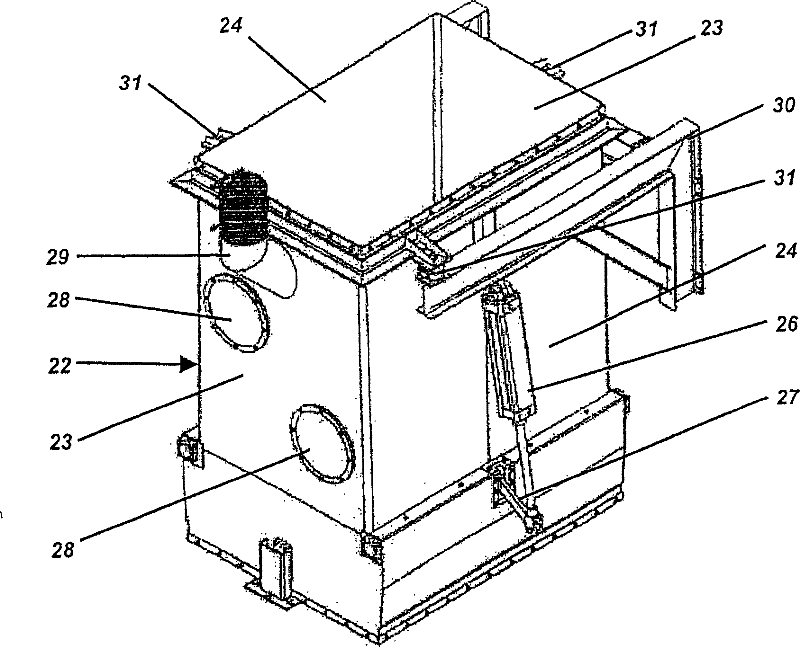

[0022] Figure 1 to Figure 3 The shown equipment can be briefly described as comprising the following parts: feed chute 1 through which dry pulp is fed, then degassing or pre-compacting device 2, distribution device 3, two chutes Section 4 , two weighing devices 5 , two prefill chambers 6 with pushers 7 , and a pressing chamber 8 with pressing dies 34 and pressing punches 9 . exist figure 2 The cross-sectional view of FIG. 1 shows a pre-compaction device 2 comprising two endless rotating belts 10 forming a pressing area 11 which in the illustrated embodiment narrows substantially downwards in a wedge shape.

[0023] The air-permeable rotating belt 10 runs around five rollers and over the sliding surface of a perforated plate 12 on a suction box 13 in this embodiment. Since the rotating belt 10 is gas permeable, the gas pressed out during the pre-compaction can be discharged by the suction box 13 through the rotating belt 10 . In the direction of motion of the rotating belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com