Yoke, electromagnetic actuator, and stirling engine

A technology of electromagnetic actuators and yokes, applied in the directions of machines/engines, engine components, electric components, etc., can solve the problems of complex structure, low durability, increased manufacturing cost, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

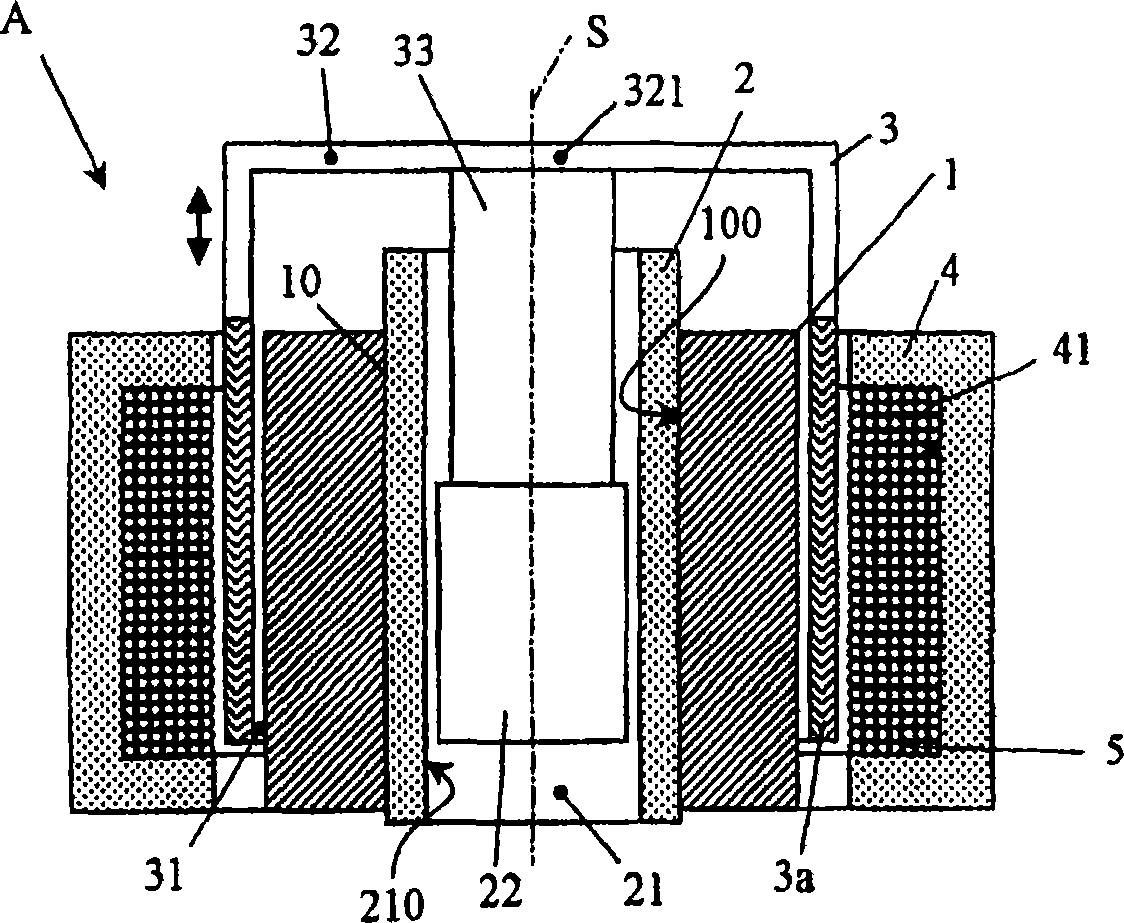

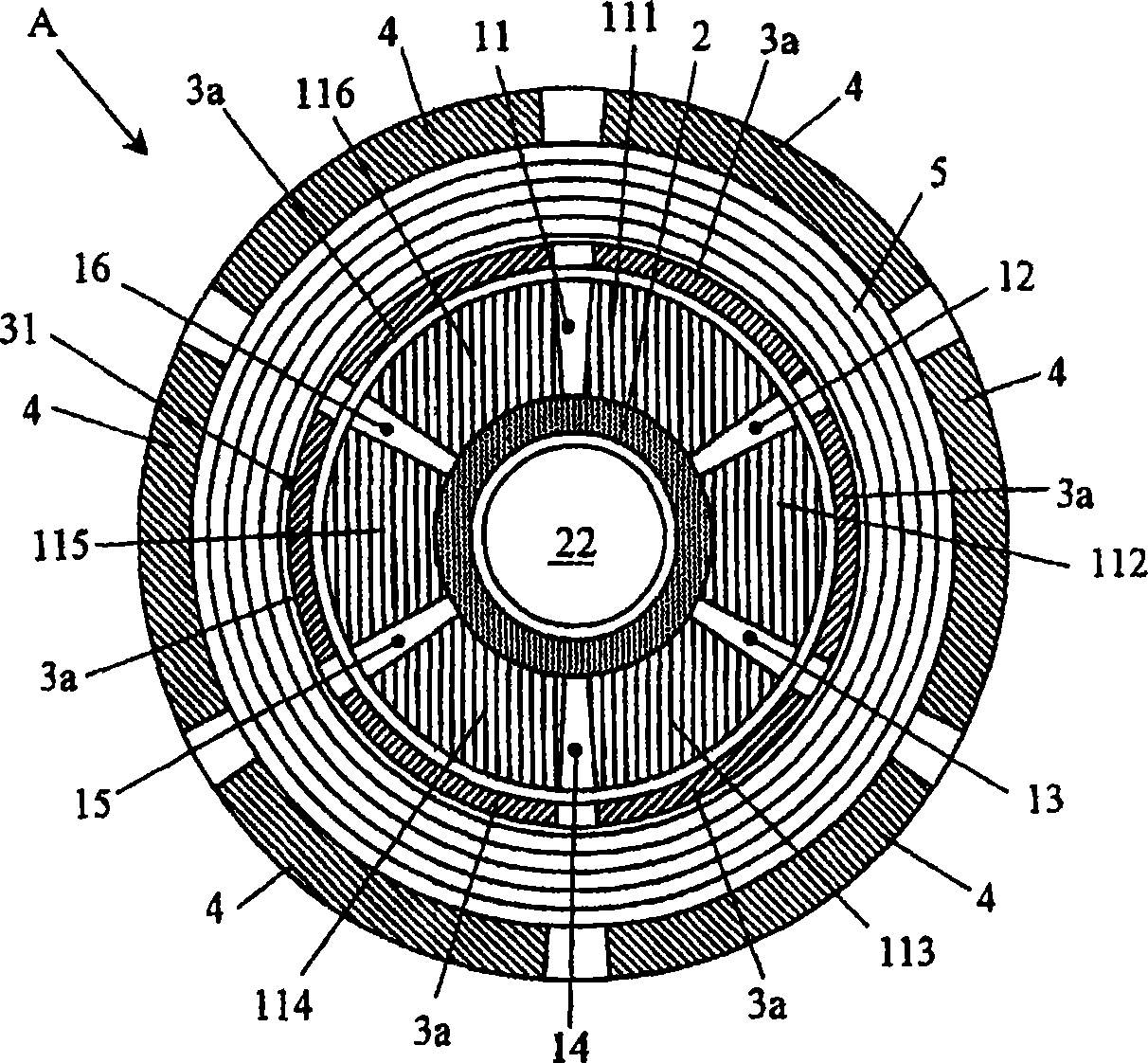

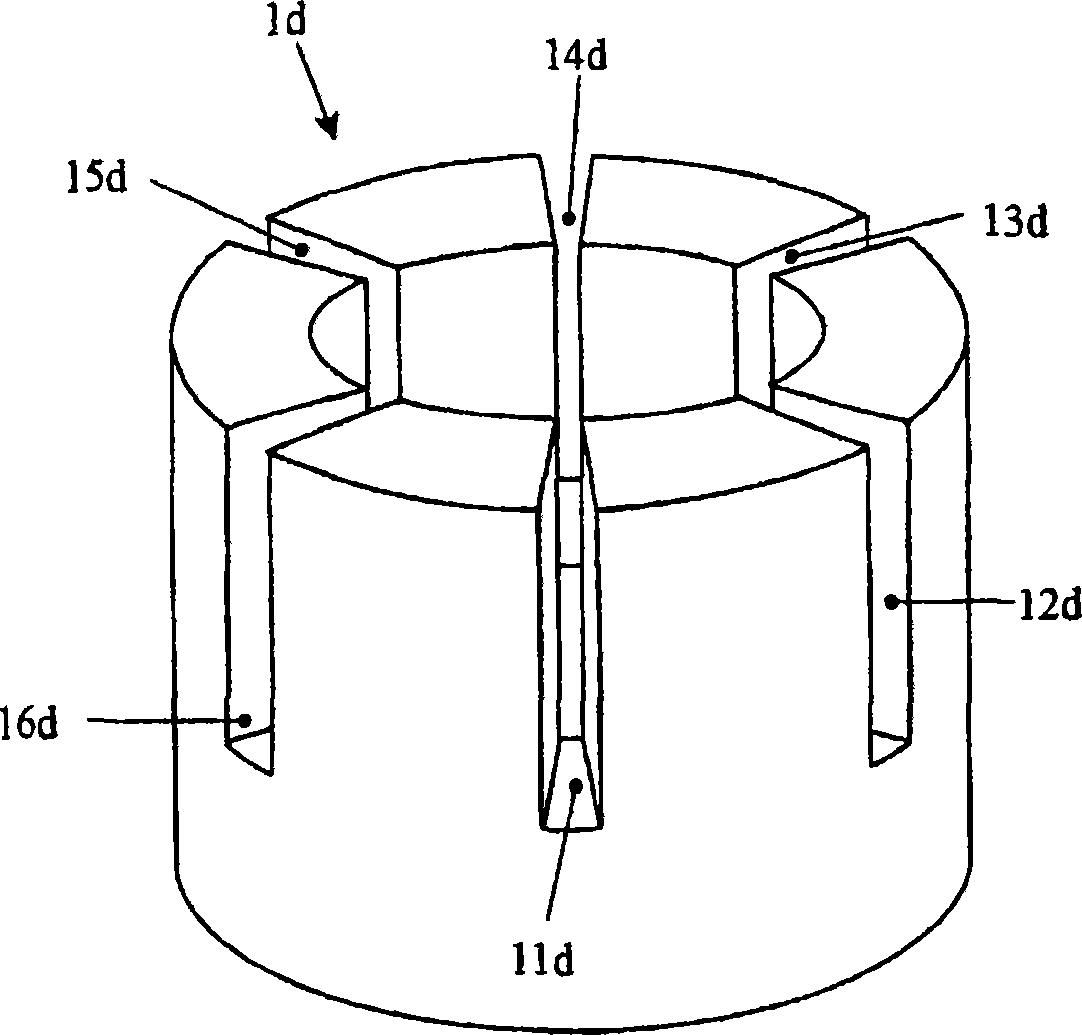

[0064] Hereinafter, a first embodiment of the present invention will be described with reference to the accompanying drawings. Figure 1A It is a sectional view of an example of the linear actuator of the present invention. Figure 1B for Figure 1A Plan view of the linear actuator shown in .

[0065] Figure 1A and Figure 1B The linear actuator A shown in has: a cylindrical inner yoke 1, a cylinder 2 inserted into an inner peripheral surface 100 of a cylinder portion 10 of the cylindrical inner yoke 1, provided on the inner yoke 1 The reciprocating motion member 3 outside but not in contact with the reciprocating motion member 3, the outer yoke 4 disposed on the outer side of the reciprocating motion member 3 but not in contact with the inner yoke 1 and the reciprocating motion member 3, and the outer yoke 4 disposed on the outer yoke 4 The coil 5 on the groove portion 41 on the inner peripheral surface. The inner yoke 1 , the cylinder block 2 , the reciprocating motion 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com