Joint gap adjusting method of flate-type siren and its adjusting clamp

A contact gap, flat type technology, applied in the field of contact gap adjustment, can solve the problems of large deviation of the contact gap, time-consuming adjustment, poor assembly accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. In addition, the drawings are viewed according to the direction of the reference numerals. In addition, all the screws will be described as right-handed screws.

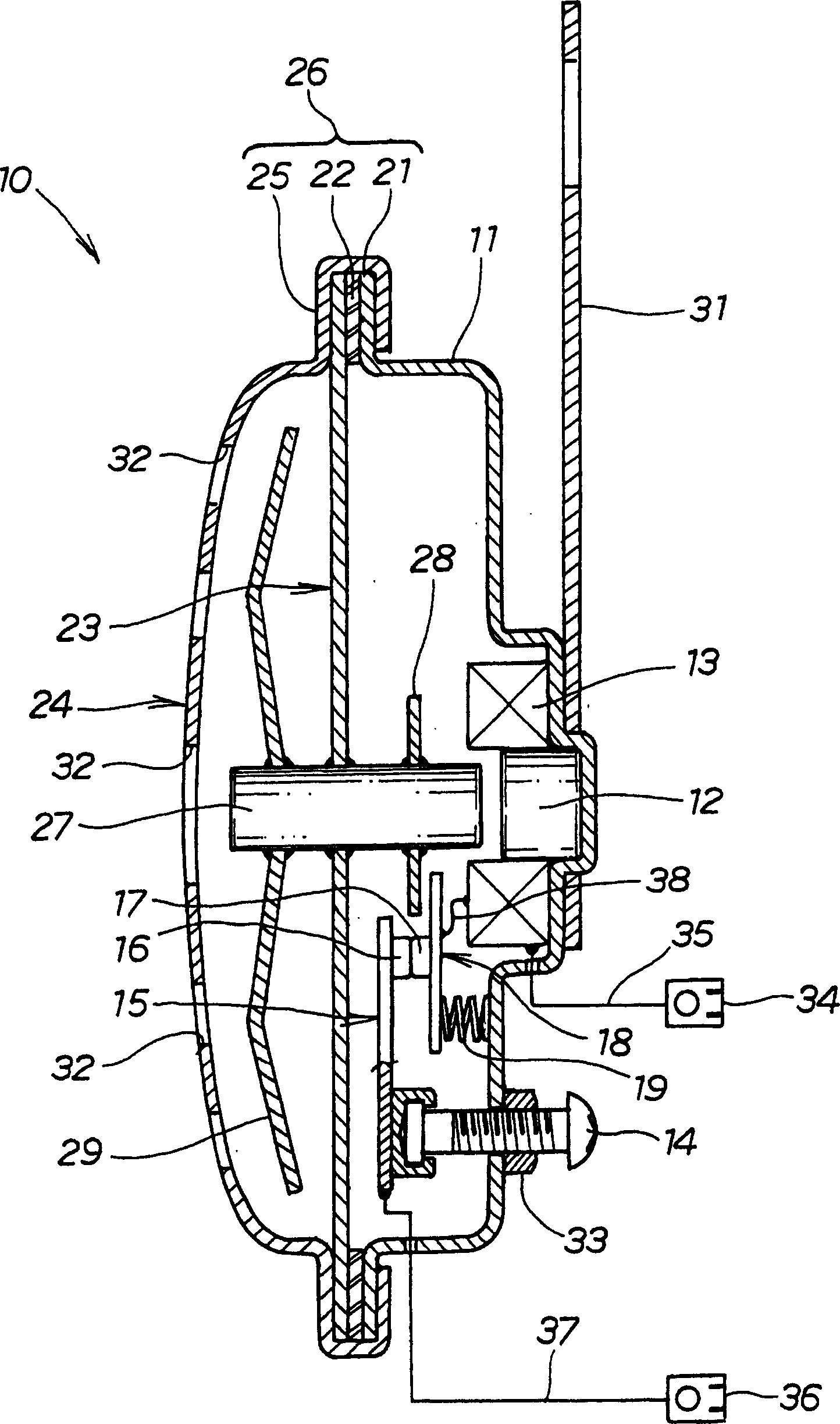

[0049] figure 1 It is a cross-sectional view of a flat siren as an object to be adjusted according to the present invention. The flat alarm 10 accommodates a fixed iron core 12 and an exciting coil 13 in a flat housing 11, and makes the adjusting screw 14 protrude into the housing 11, and uses the adjusting screw 14 to support the fixed contact 16 through the fixed contact rod 15, The movable contact 17 is arranged opposite to the fixed contact 16, the movable contact 17 is supported by the movable contact rod 18, and the movable contact rod 18 is biased in the contact closing direction by the spring 19, and the protrusion of the case 11 A vibrating plate 23 is placed on the edge 21 via a gask...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap