Motor

A technology for electric motors and electric wires, which is applied in the field of small electric motors, and can solve the problems of difficult wire clamping, poor wire clamping accuracy, poor connection, etc., and achieves good clamping and elimination of poor welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

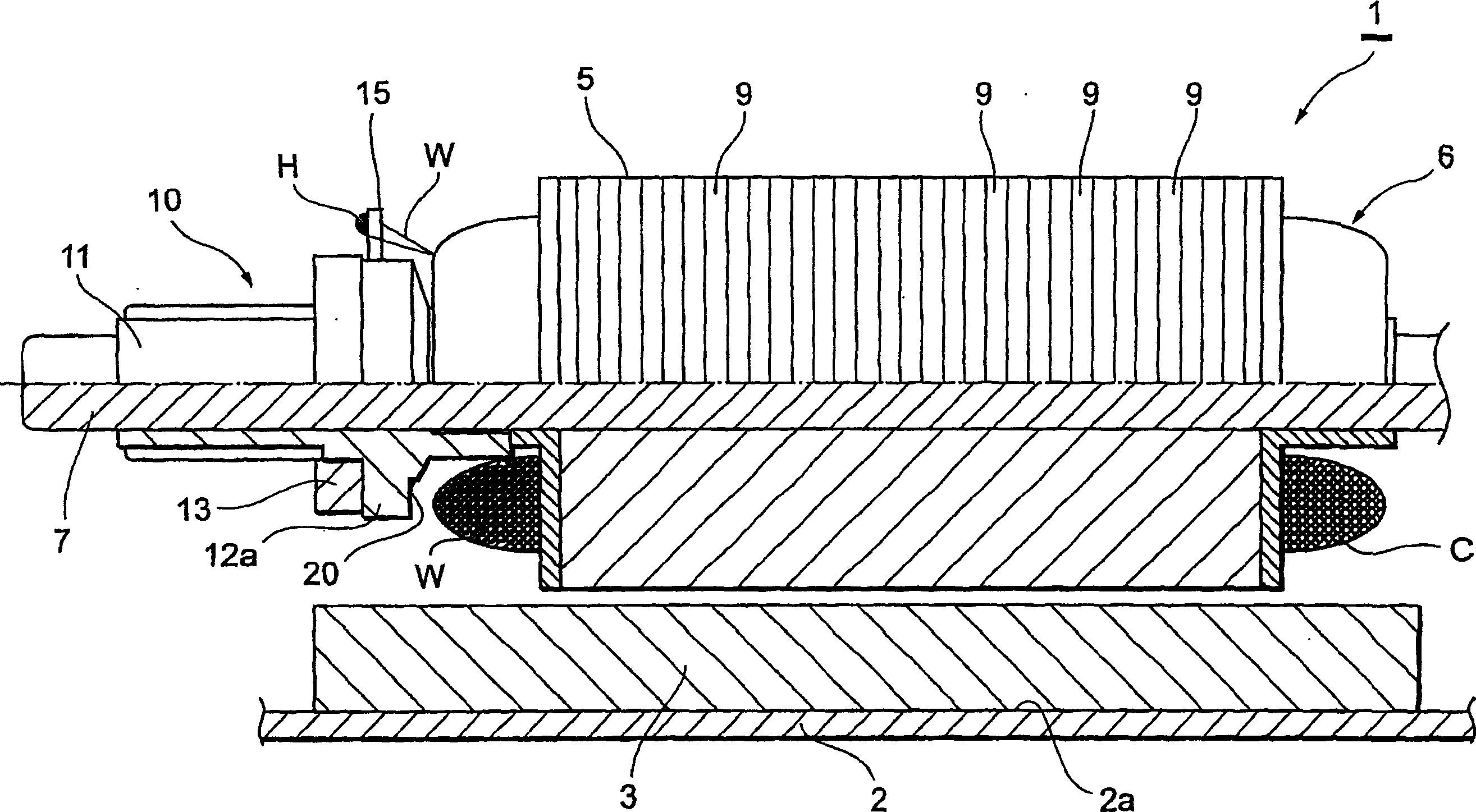

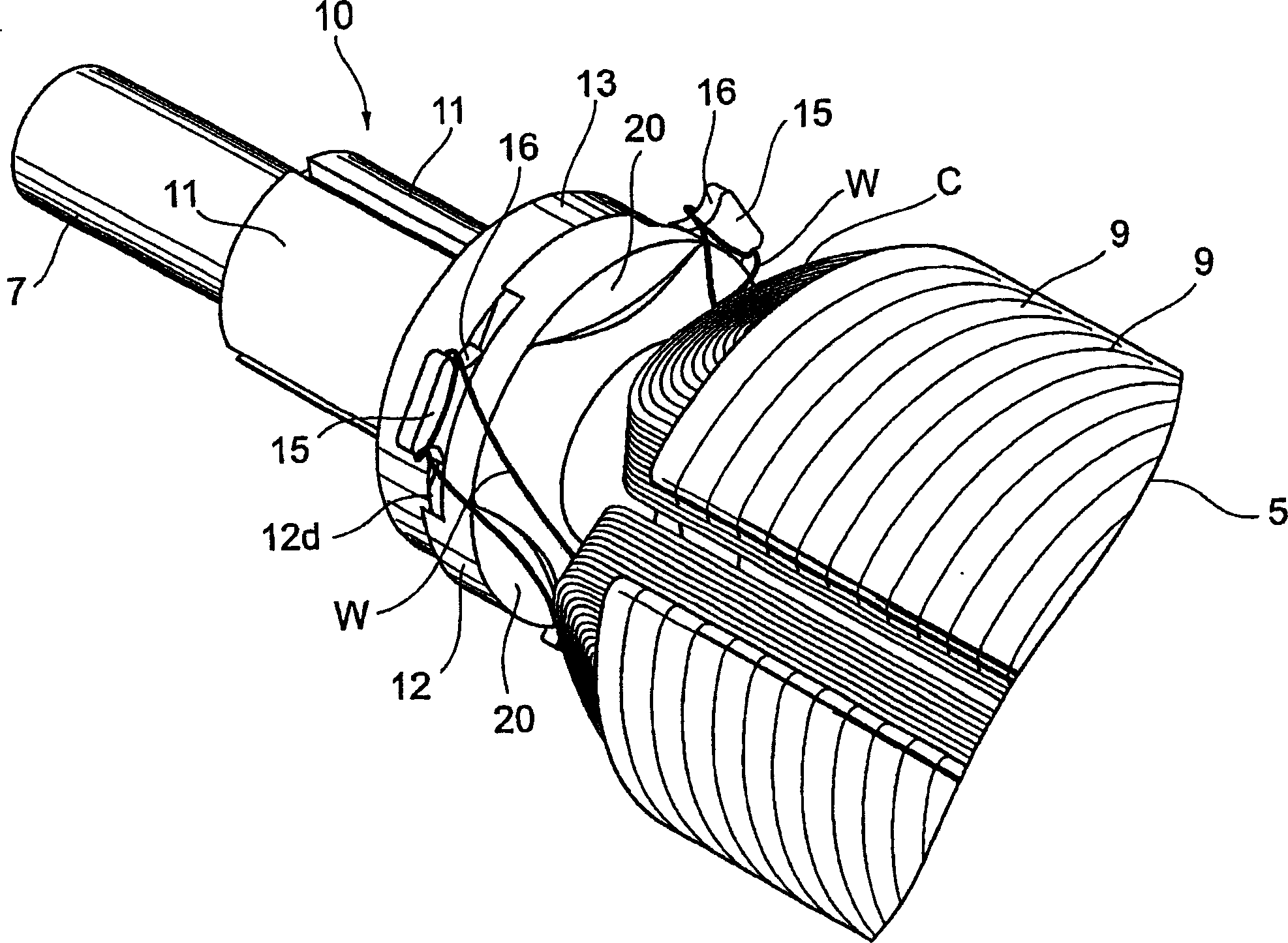

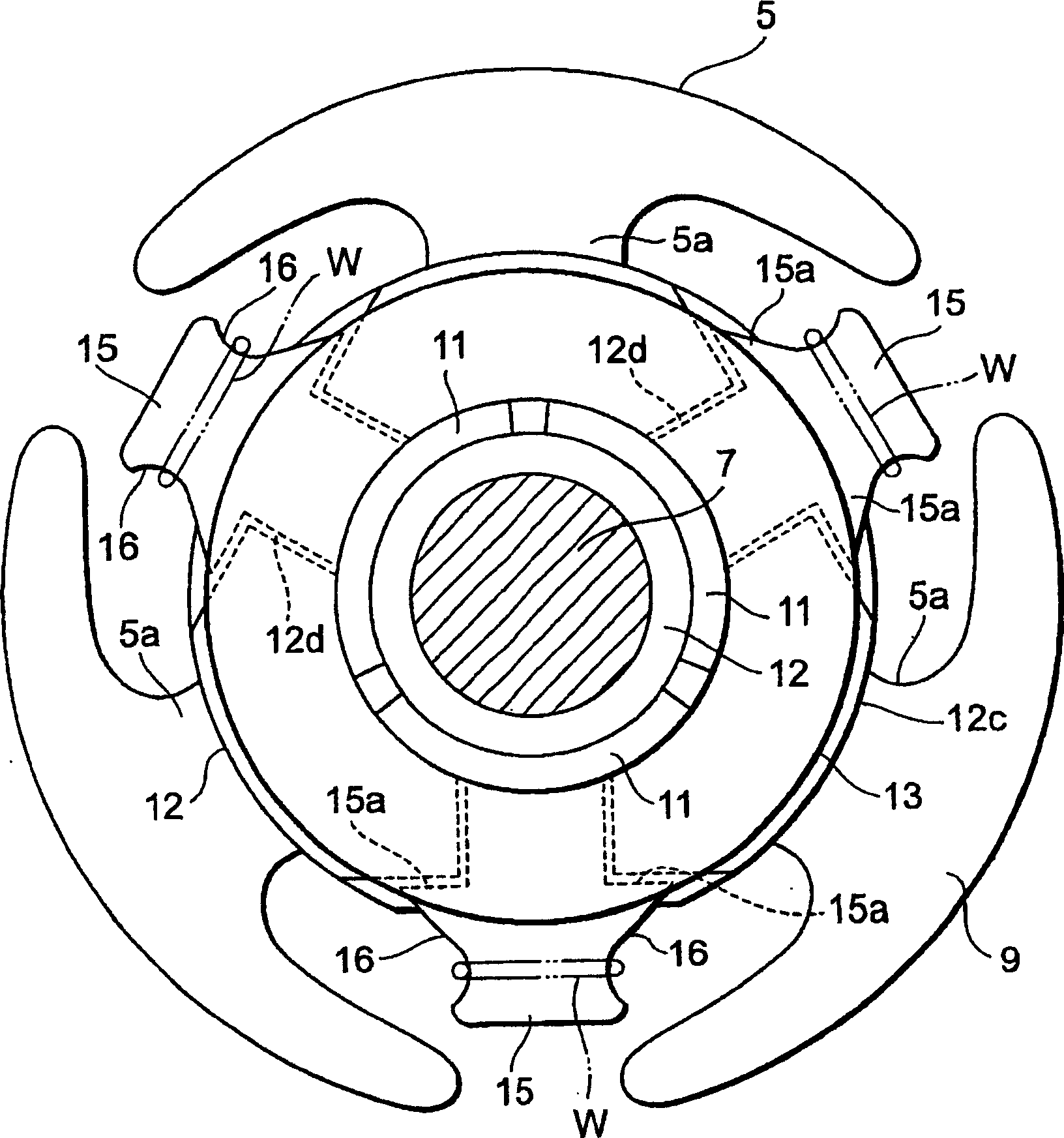

[0028] Hereinafter, preferred embodiments of the motor of the present invention will be described in detail with reference to the accompanying drawings.

[0029] Such as Figure 1 ~ Figure 3 As shown, the motor 1 is composed of a tubular motor, and has a cylindrical metal casing 2, and a resin bracket (not shown) for assembling a pair of brushes is fixed to the rear end of the casing 2. The motor 1 is a small motor, and the housing 2 has a cylindrical shape with a diameter of 10 mm or less (for example, 6 to 3 mm) and a length of about 1 cm. A stator 3 and a rotor 6 are accommodated in the small housing 2 .

[0030] A stator (magnet) 3 made of permanent magnets having N and S poles is fixed on the inner wall surface 2a of the casing 2, and a rotor 6 is accommodated inside the casing 2. The rotor 6 has a coil C, and the wire W of the coil C It is wound on the pole 5a of the core 5 having three core slots (slots). In addition, the iron core 5 of the rotor 6 is formed by lamina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com