Sealing structure for battery and battery employing sealing structure for battery

A battery and sealing technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of spot welding operability limitations, low battery current collection, poor discharge characteristics, etc., to eliminate poor welding and increase electrical conductivity. The effect of improving the area and current collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Specific embodiments of the present invention will be described below using the drawings.

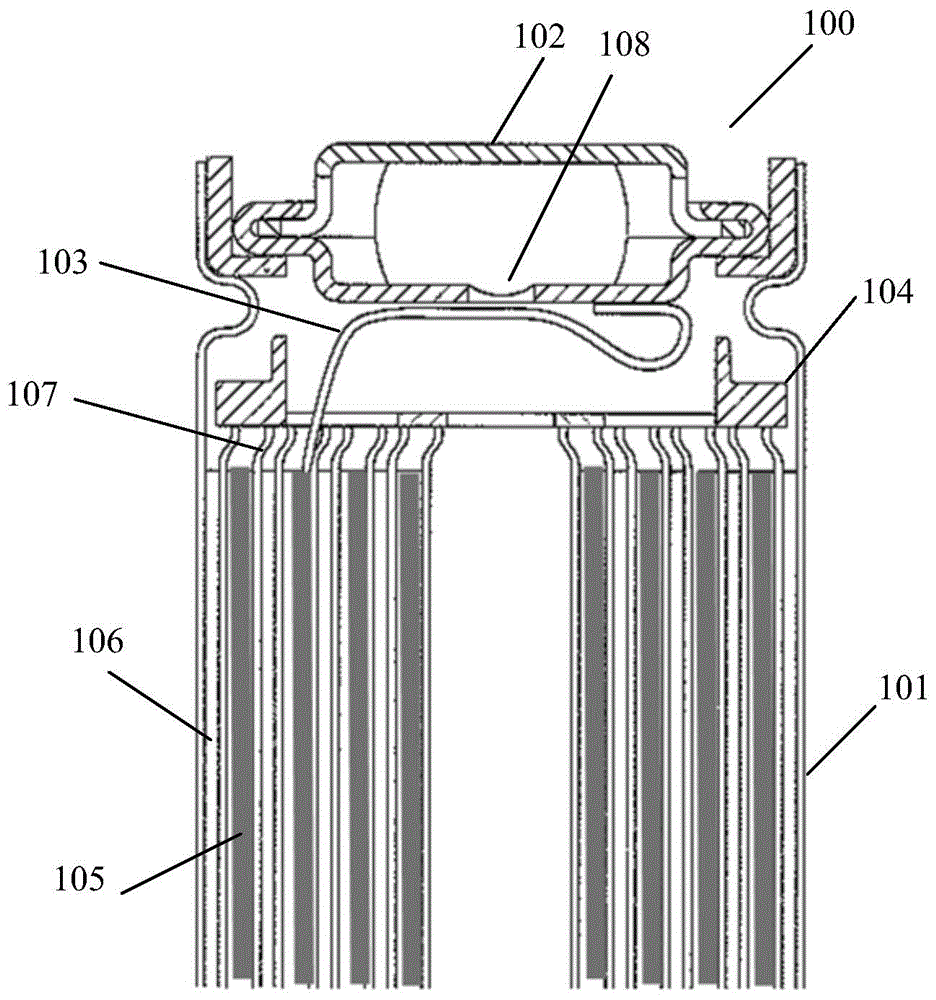

[0064] In this embodiment, if Figure 4 As shown in , the schematic structure of the battery 10 of the present invention is shown.

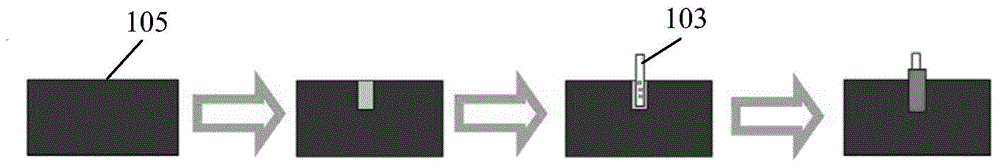

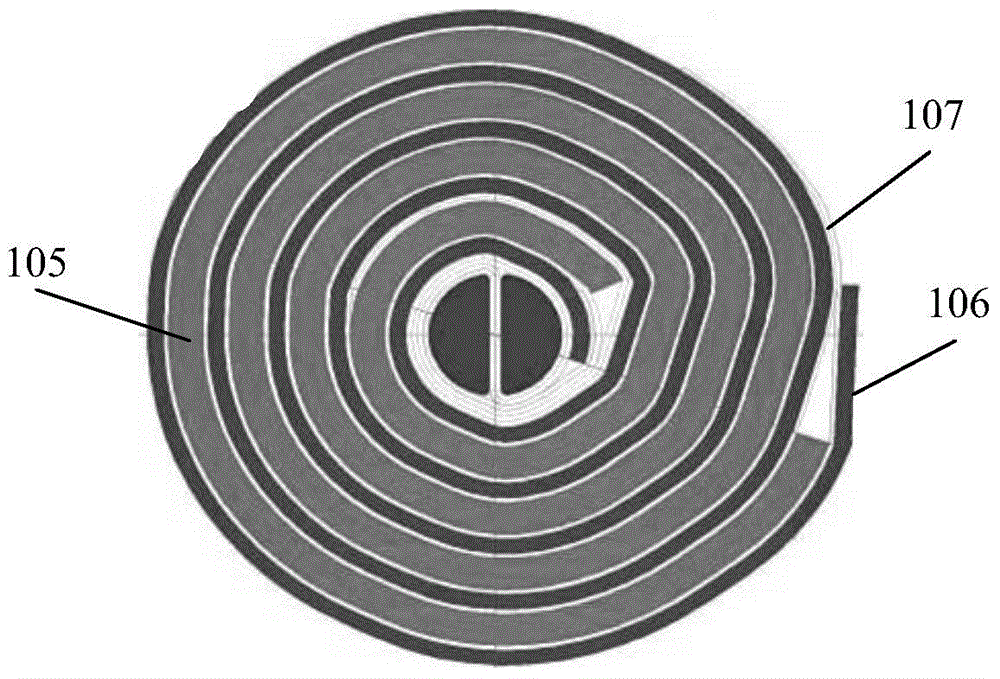

[0065] The battery 10 will be described as an example where the battery 10 is a cylindrical nickel metal hydride battery. The battery 10 has a positive plate 15; a negative plate 16 is spaced apart from the positive plate 15; a spacer 17 is arranged between the positive plate 15 and the negative plate 16 to insulate the positive plate 15 and the negative plate 16; one end ( Figure 4 The upper end of the middle) opening, containing the positive plate 15, the negative plate 16 and the spacer 17; the insulating sheet 20, arranged on the opening of the housing 11; and the sealing member 19, arranged on the insulating sheet 20, sealing the housing 11 , and is electrically connected to the positive plate 15, including the sealing plate 12 and the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com