Method for controlling microscopic bubble nucleation in fluid polymer material production and its apparatus

A technology of polymer materials and generating devices, applied in chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve instability, increase equipment costs and failure rates, non-nucleation parts and nucleation Some problems such as separation and control are not easy to achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

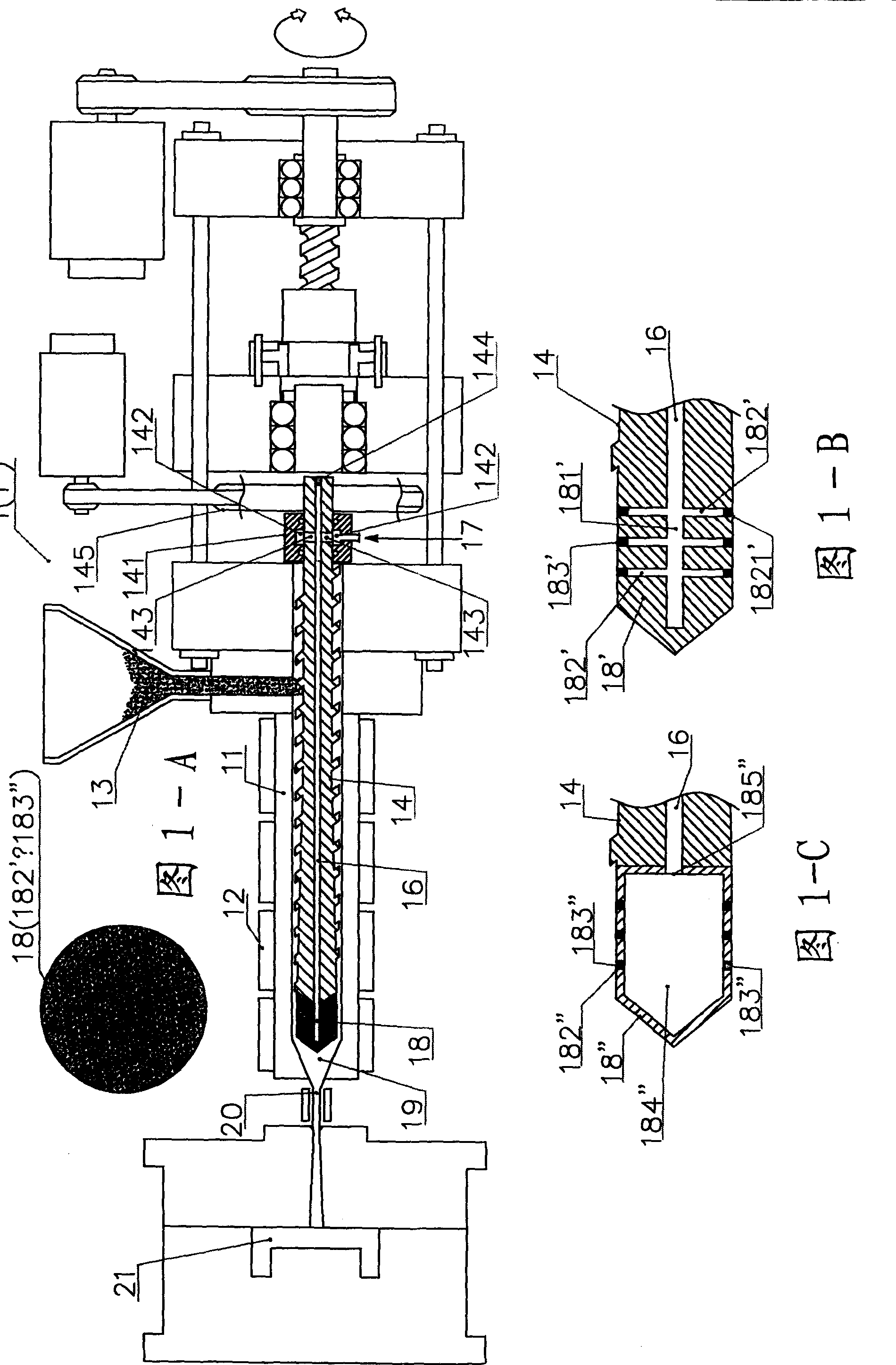

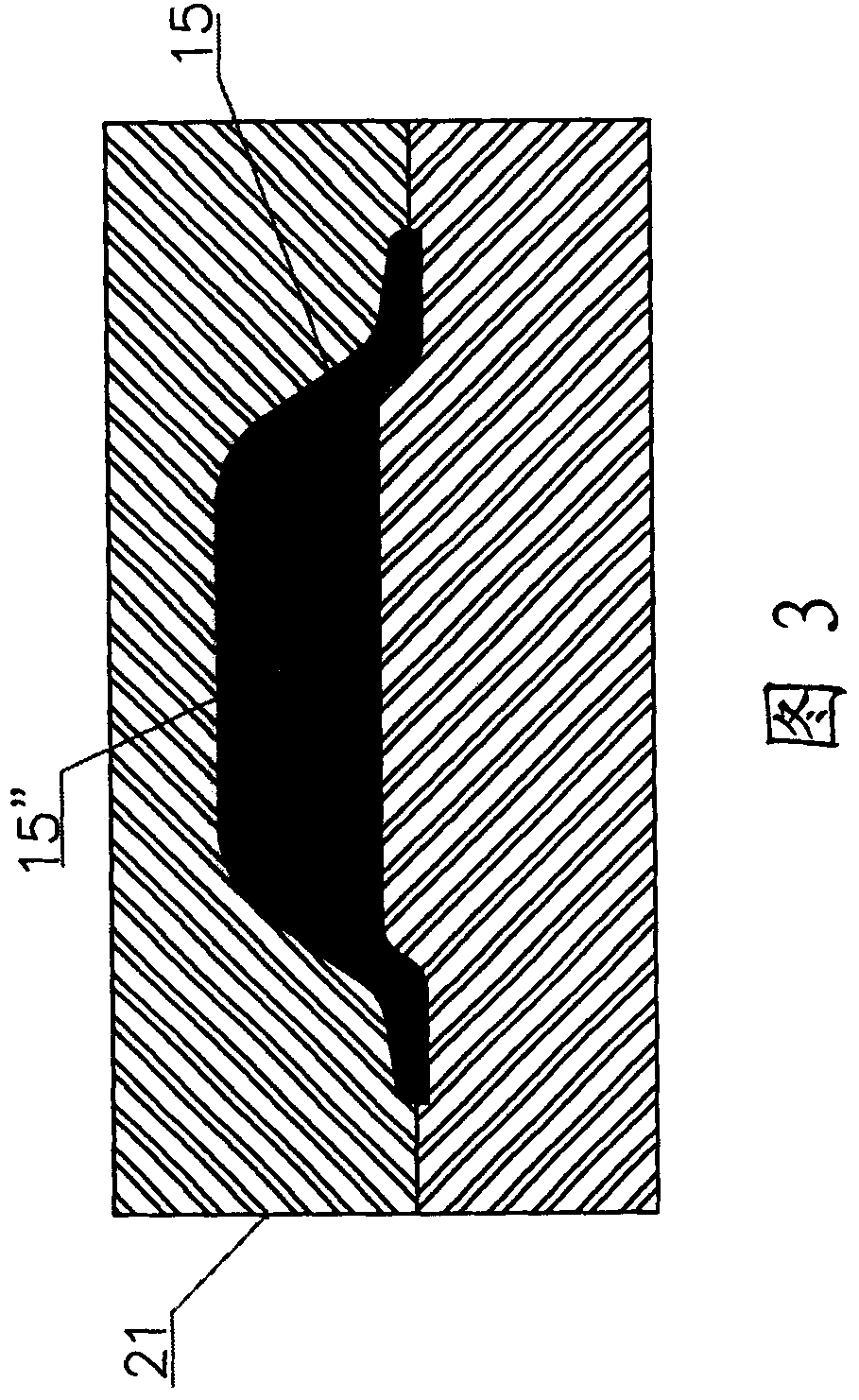

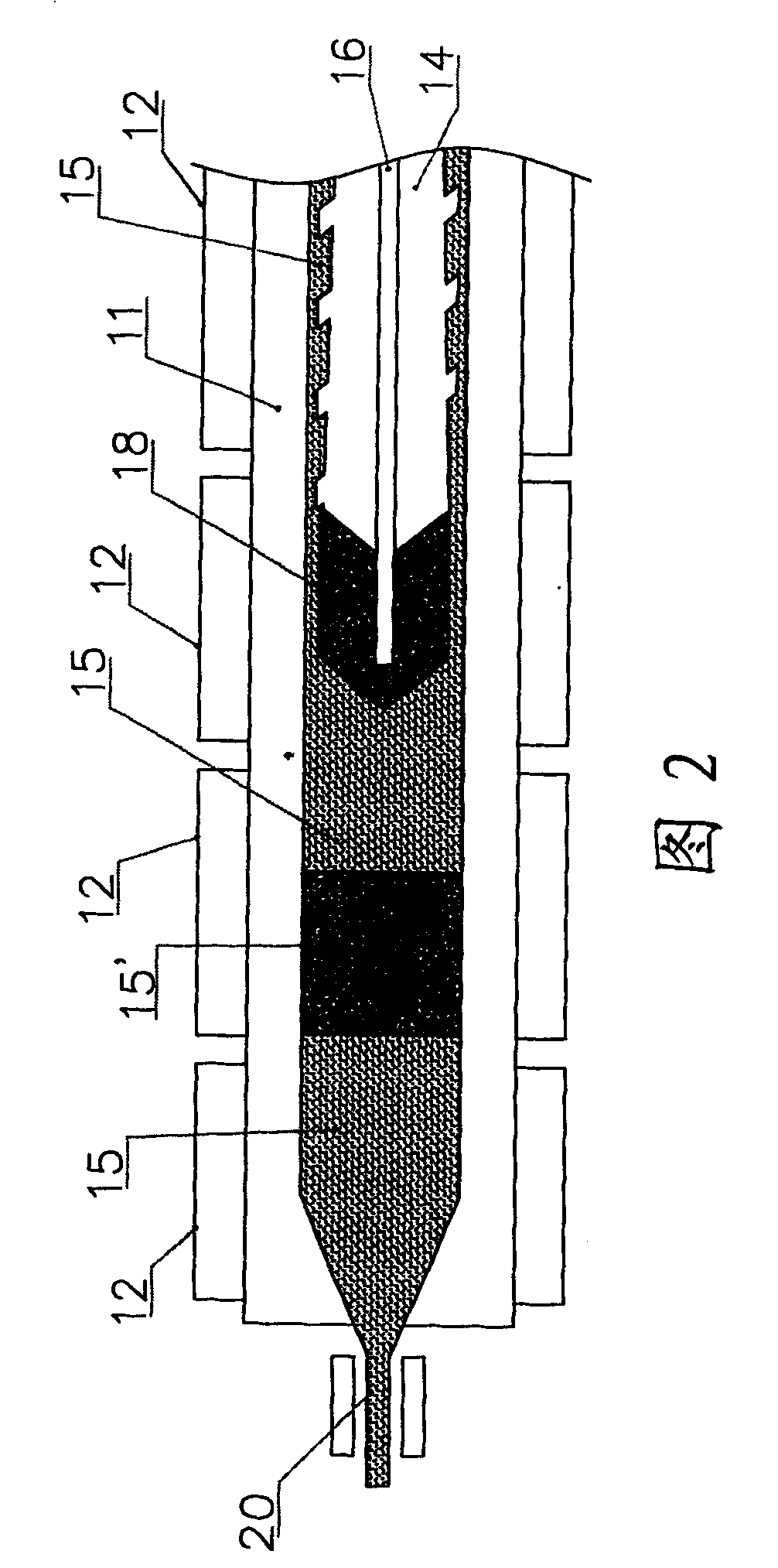

[0033] The first embodiment of the present invention, please refer to Fig. 1 and Figure 1-A , a heater 12 is installed on the outer edge of the material pipe 11 in the injection or extrusion machine 1, 1' to melt the polymer material 13, and a conveying screw 14 is installed in the material pipe 11, through which the conveying screw 14 Stir to push the molten fluid polymer material 15; and the foaming source is to use all applicable gases, such as carbon dioxide, nitrogen or other gaseous sources that can be used for foaming, to carry out the foaming reaction of the polymer material A gas delivery pipe 16 is established in the delivery screw 14, and a screw shaft seat 141 is fixed on the transmission disc 145 at the rear end, and the gas delivery pipe 16 rear end is blocked with a plug 144; the screw shaft An annular air groove 142 is arranged in the seat 141, and an air inlet 17 communicated with the annular air groove 142, and several communication holes 143 are penetrated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com