High speed filling machine for medicine liquor

A filling machine, high-speed technology, applied in the field of high-speed liquid medicine filling machine, can solve the problem of low filling efficiency, and achieve the effect of high filling efficiency, improved production efficiency, continuous and multi-row filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

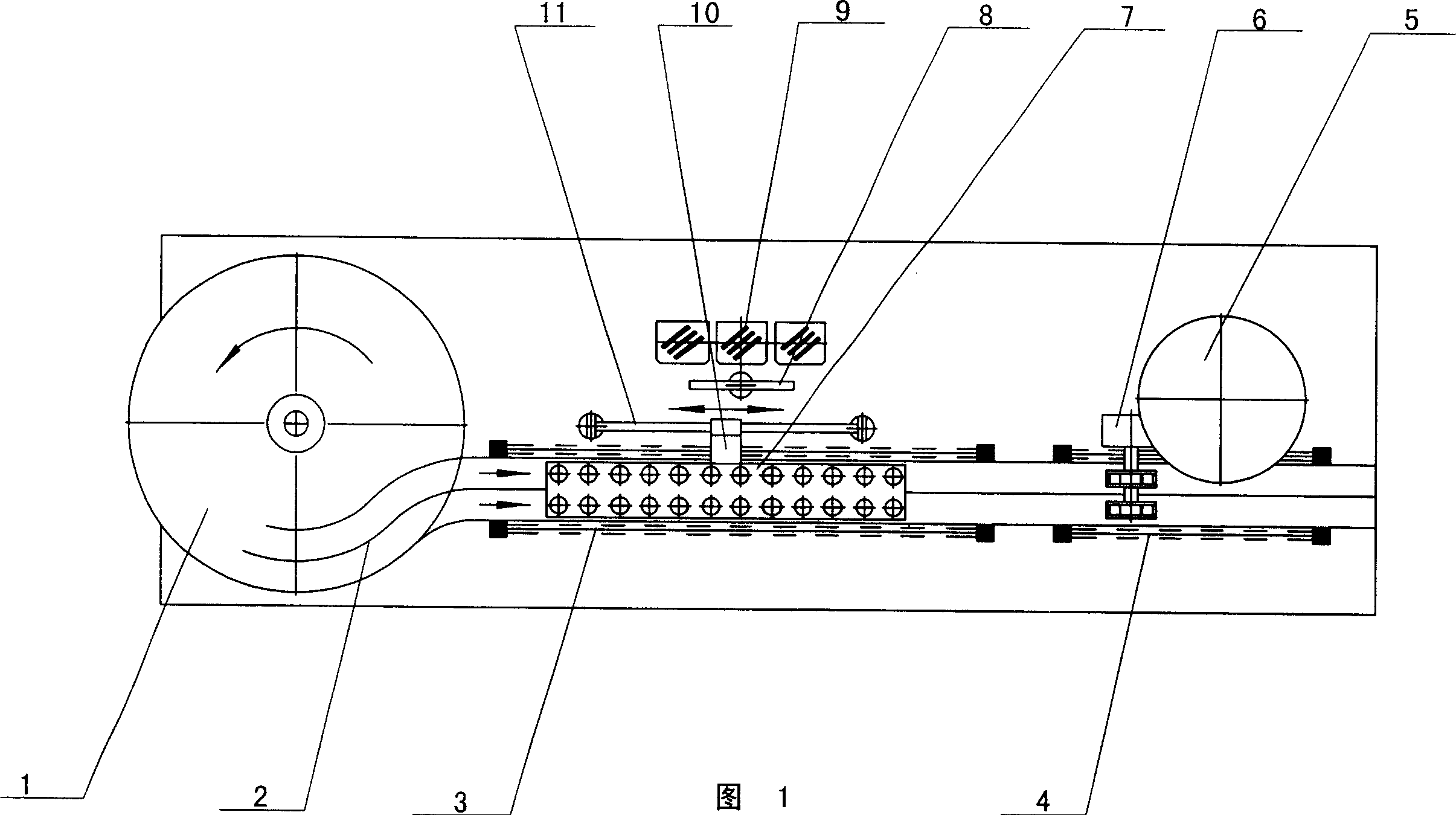

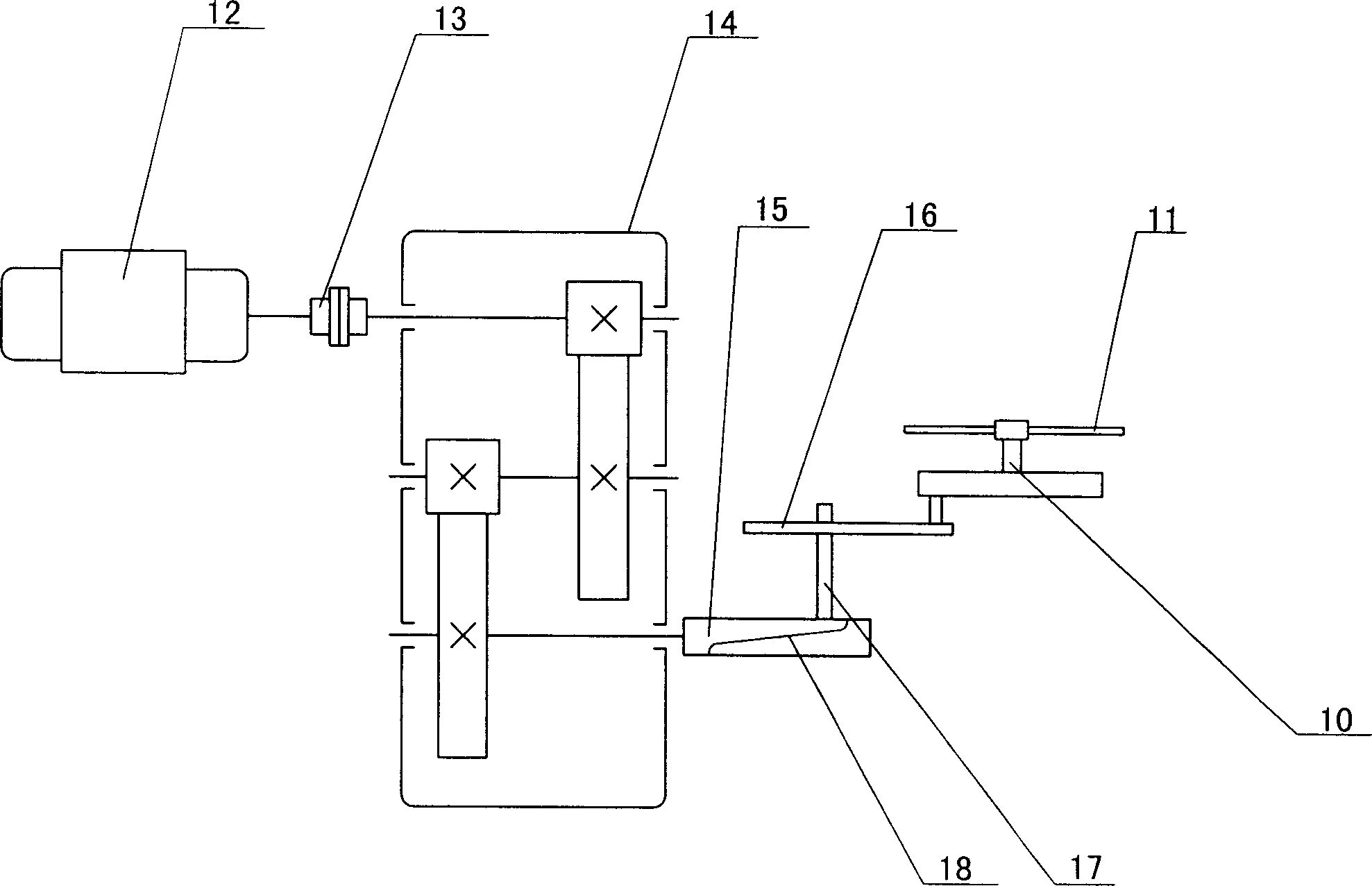

[0014] As shown in the figure, the high-speed liquid medicine filling machine according to the present invention includes a bottle separating tray 1, a medicine bottle conveying track, a filling spiral track 3, a corking spiral track 4 and a corking mechanism 6, and the filling spiral track 3 Correspondingly, there are 24 filling hoses connected to the peristaltic pump 9, which are respectively connected to 6 peristaltic pumps. The filling hoses are erected on the hose rack 8. The filling hose of each hose The opening corresponds to the position of filling the medicine bottle, and the rubber hose holder 8 is connected to the reciprocating device consistent with the conveying track of the medicine bottle. The reciprocating moving device is composed of a moving frame 10 and a guide column 11. The moving frame 10 is fitted on the guiding colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com