Assembly of tire and rim

A polymer and composition technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve problems such as difficult to reduce the weight of the inner support body, unavoidable deterioration of durability, increased heating time, tire damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0188] The preparation of the compressed elastic object is not particularly limited and may include, following the first to fourth methods. The first to third methods relate to a production method of a compressed elastic object including a composite material in a hollow body, and the fourth method relates to a production method of a compressed elastic object including a gas in a hollow body.

[0189] The first method is a method in which a bag-shaped hollow body is provided and a composite material is placed therein and the opening portion of the bag-shaped hollow body is closed thereafter. The method of closing the opening depends on the material used for the hollow body, but may include, for example, an internal heating system such as a high-frequency heating process, an ultrasonic sealing process, etc., and an external heating system such as a heat sealing process, a pulsation sealing process, and the like.

[0190] In the second method, a bag-shaped hollow body is provided and...

Embodiment 1-12

[0241] Examples 1-12, Comparative Examples 1-5

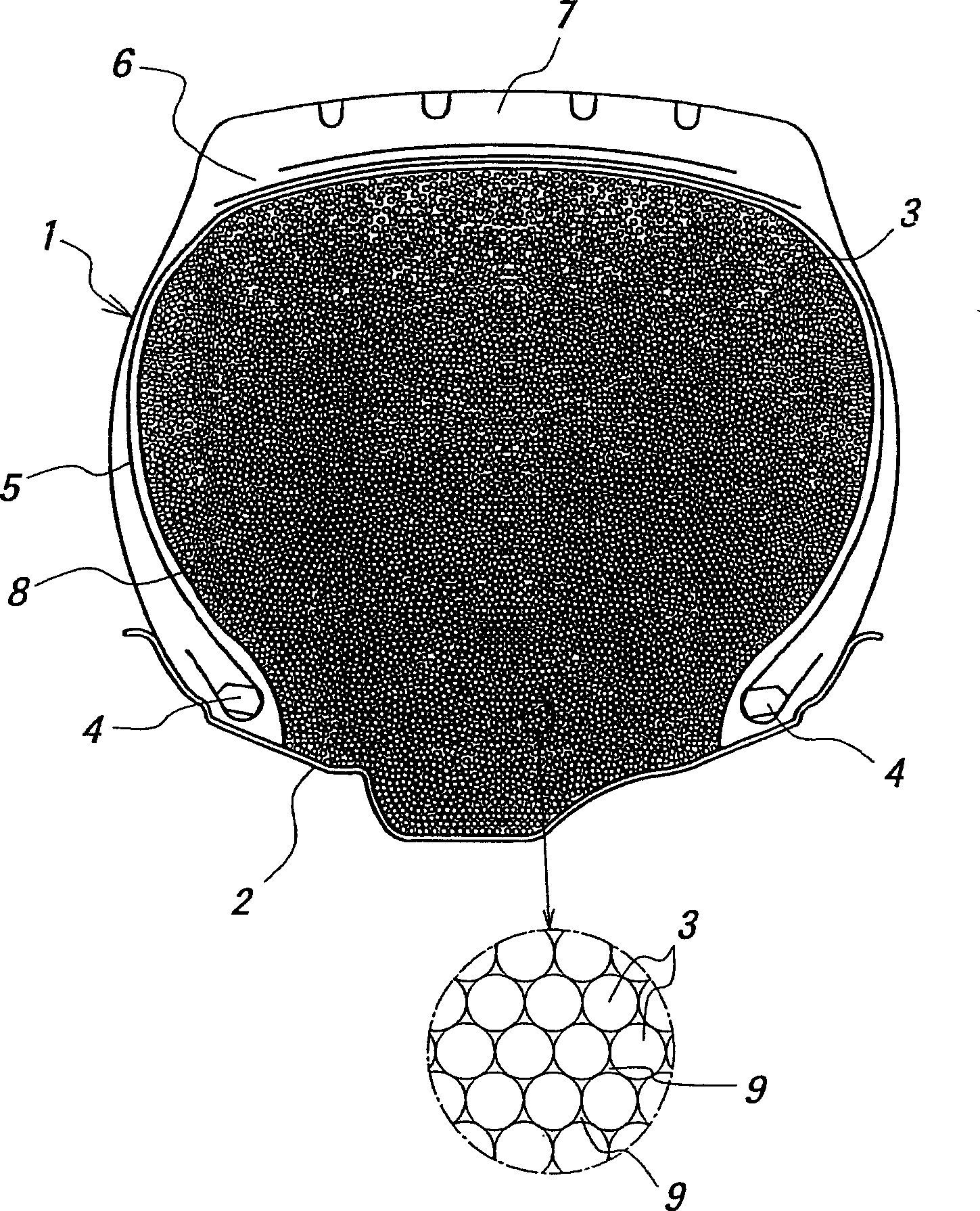

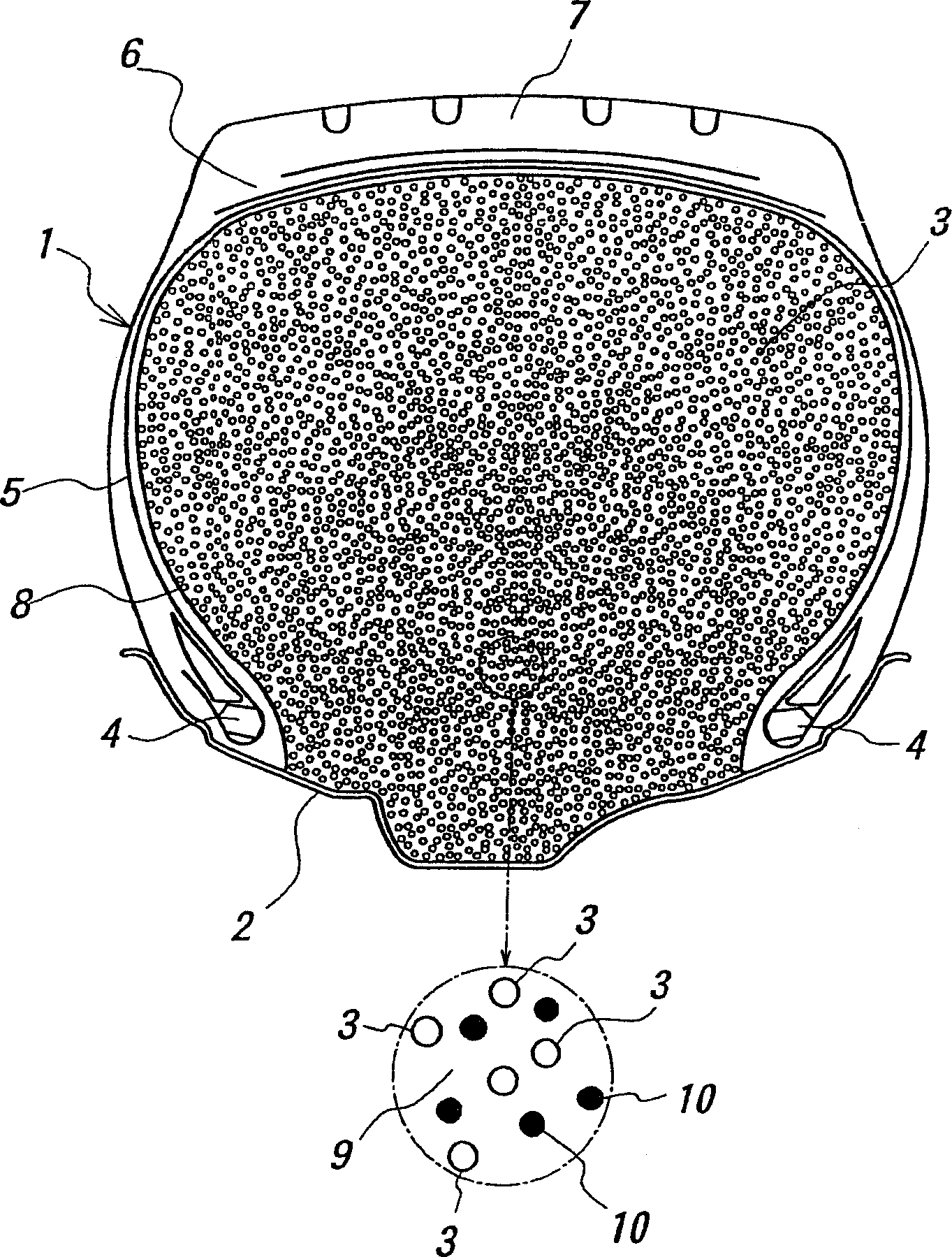

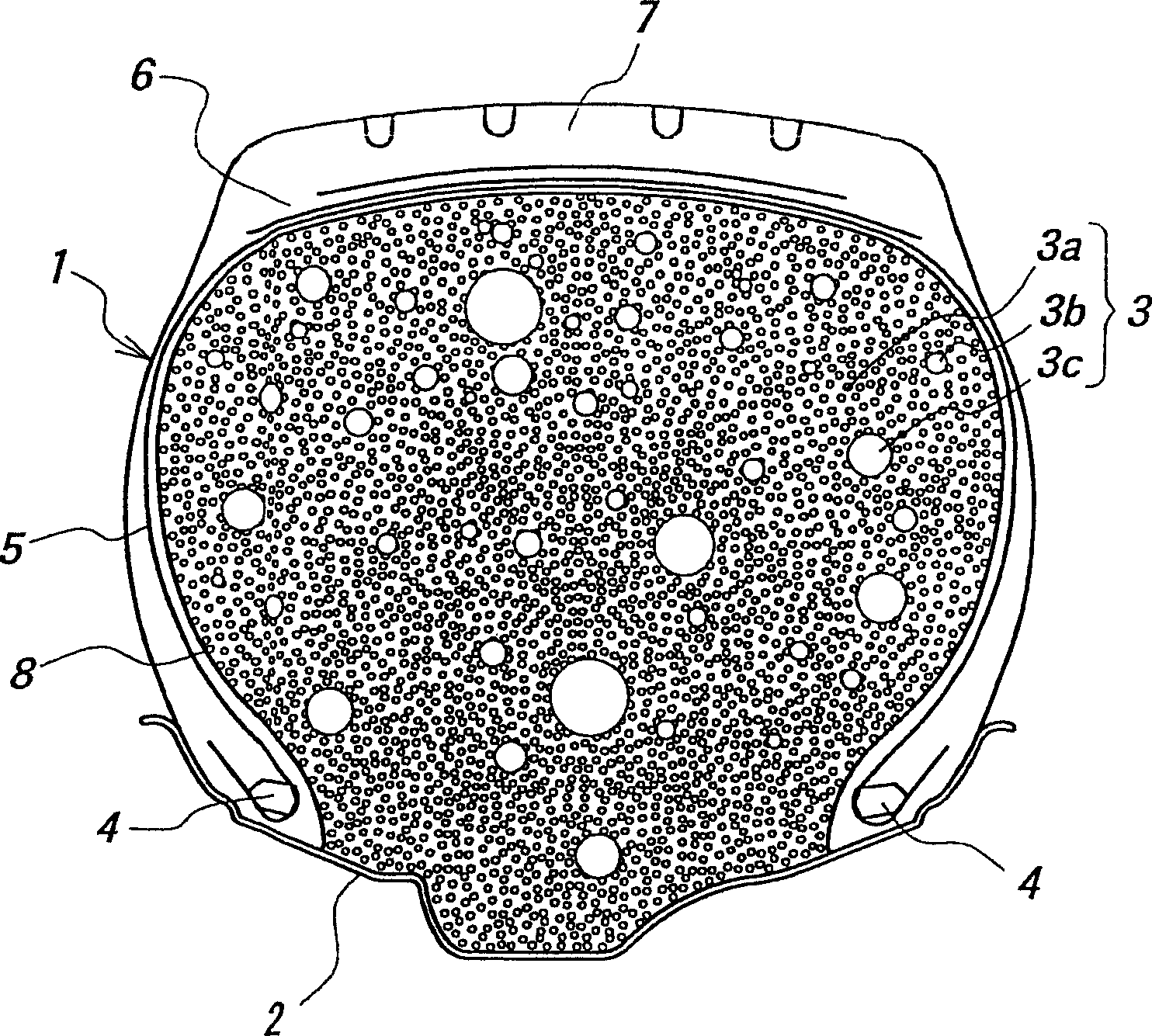

[0242] By applying particles with various specifications shown in Tables 1 and 2 to figure 1 The tire of the structure shown is a combination of passenger car tires with a tire size of 175 / 70R13 and a rim of 5J×13, and a combination of truck and utility vehicle safety tires with a tire size of 11R22.5 and a rim of 750×22.5. Body, as shown in the same table. Here, the tire 1 is a general structure according to the type and size of the tire of interest. In addition, the types of resin compositions constituting the continuous phase of particles in Tables 1 and 2 are shown in Table 3. The resin particles in which the gas component was coated as shown in Table 3 were heated and expanded to form particles, and the particles thus obtained were added to the inside of the tire at various average bulk specific gravities shown in Tables 1 and 2. Similarly, the types of inner liner rubber are shown in Table 4.

[0243] Here, the inner volume o...

Embodiment 13-23, comparative example 6-9

[0266] By applying particles with various specifications shown in Table 5 to figure 1 On the tire of the structure shown, a combination of a passenger car safety tire with a tire size of 205 / 60R15 and a rim with a size of 6J×15 was prepared, as shown in the same table. Similarly, a combination of truck and bus tires with a tire size of 11R22.6 and a rim with a size of 750×22.5 was prepared by applying particles having various specifications shown in Table 6. Here, the tire 1 is a general structure according to the type and size of the tire of interest. In addition, the resin compositions constituting the continuous phase of the particles in Tables 5 and 6 are shown in Table 3 above. The resin particles in which the gas components shown in Table 3 are coated are heated and expanded to form particles, and the particles thus obtained are added to the inside of the tire at the volume filling ratios shown in Tables 5 and 6. Similarly, the types of rubber used for the inner liner are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com