Electronic ballast and correspondent adjustment method

An electronic ballast, DC current technology, applied in electric light sources, electrical components, lighting devices, etc., can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The exemplary embodiment described in more detail below is a preferred embodiment of the invention.

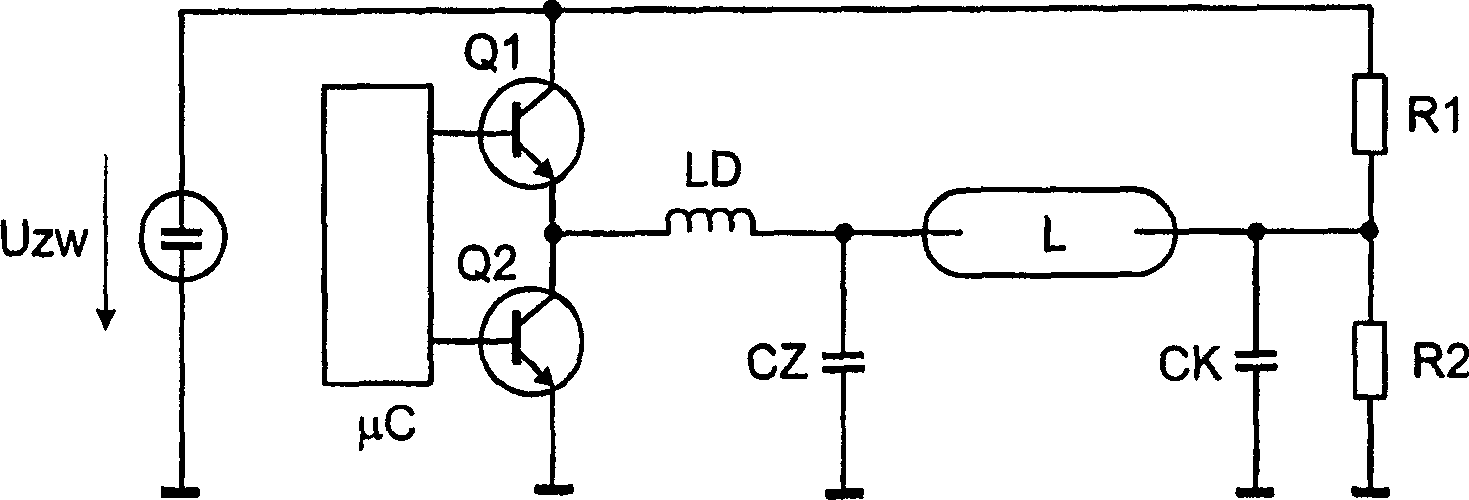

[0016] according to figure 1 In the circuit diagram shown, a fluorescent lamp L is supplied with a DC current via a voltage divider R1 / R2, which reacts in a suitable ratio to the DC intermediate circuit voltage U ZW Divide the voltage, and output the divided voltage at the tap of the voltage divider. One pole of the fluorescent lamp L is connected to the tap. In addition, capacitor CK is connected in parallel with resistor R2 in the voltage divider to ground.

[0017] The DC intermediate circuit voltage U ZW Also as the input voltage of the inverter, which in this example is implemented as a half-bridge comprising a series circuit with two transistors Q1 and Q2. Transistors Q1 and Q2 are controlled by the microcontroller μC at the desired duty cycle.

[0018] A light sensor LD is connected to a node between transistors Q1 and Q2. The other side of the lamp inducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com