High speed air cushion vessel hull

A hovercraft and hull technology, applied in air cushion, transportation and packaging, vehicle parts, etc., can solve the problems of astonishing energy consumption, limited load capacity of hovercraft, complex structure, etc., and achieve the effects of reducing hull weight, fast speed, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

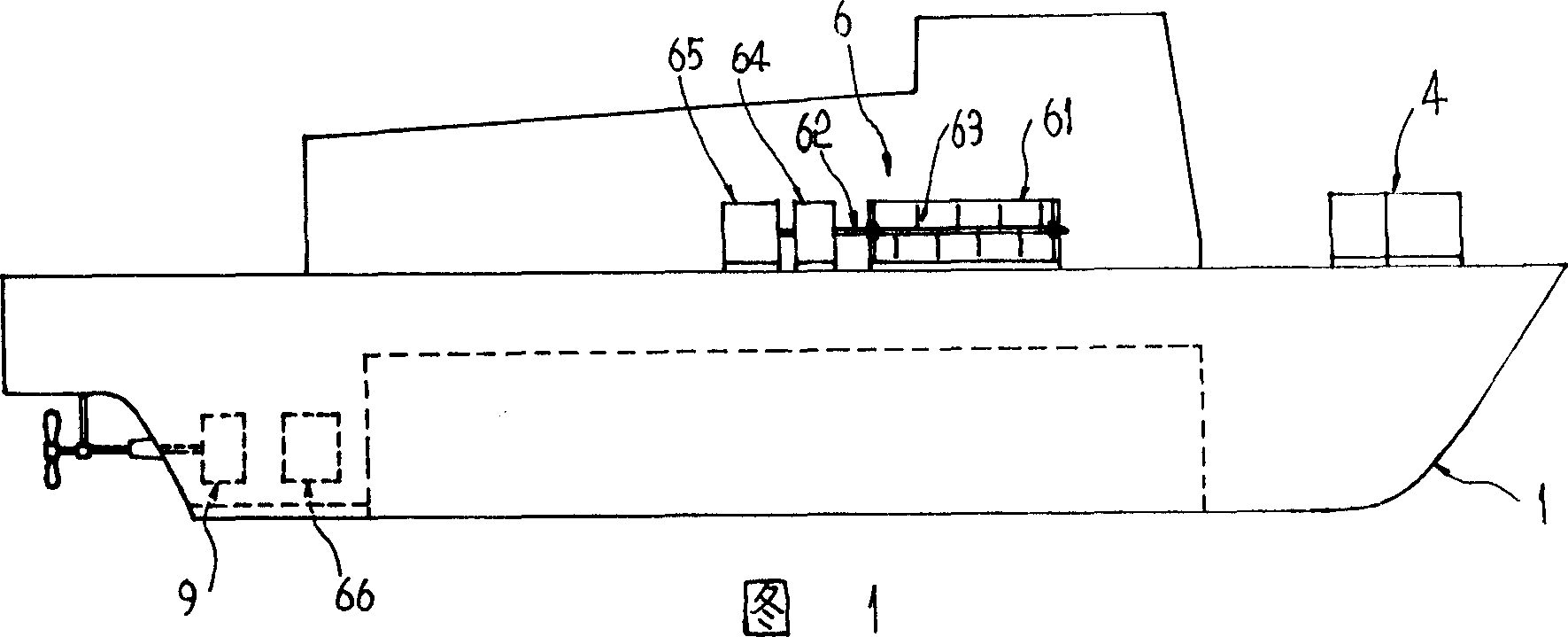

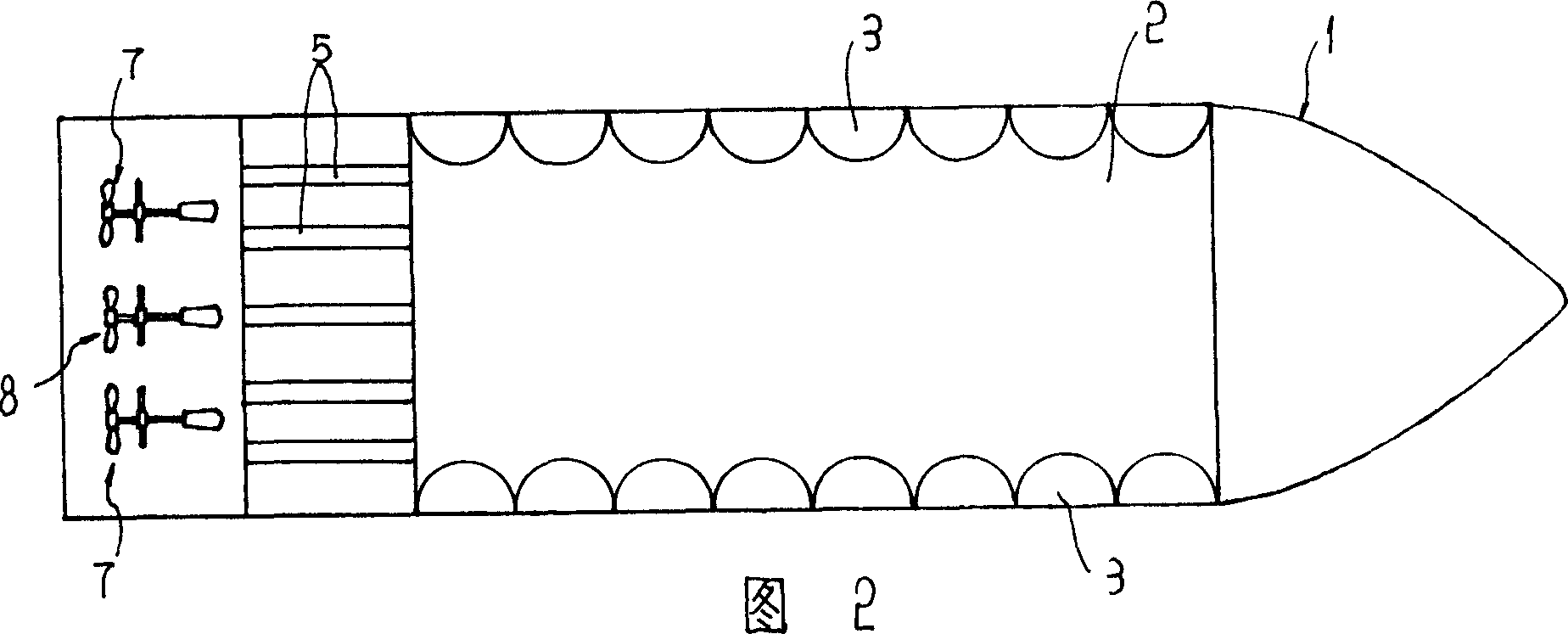

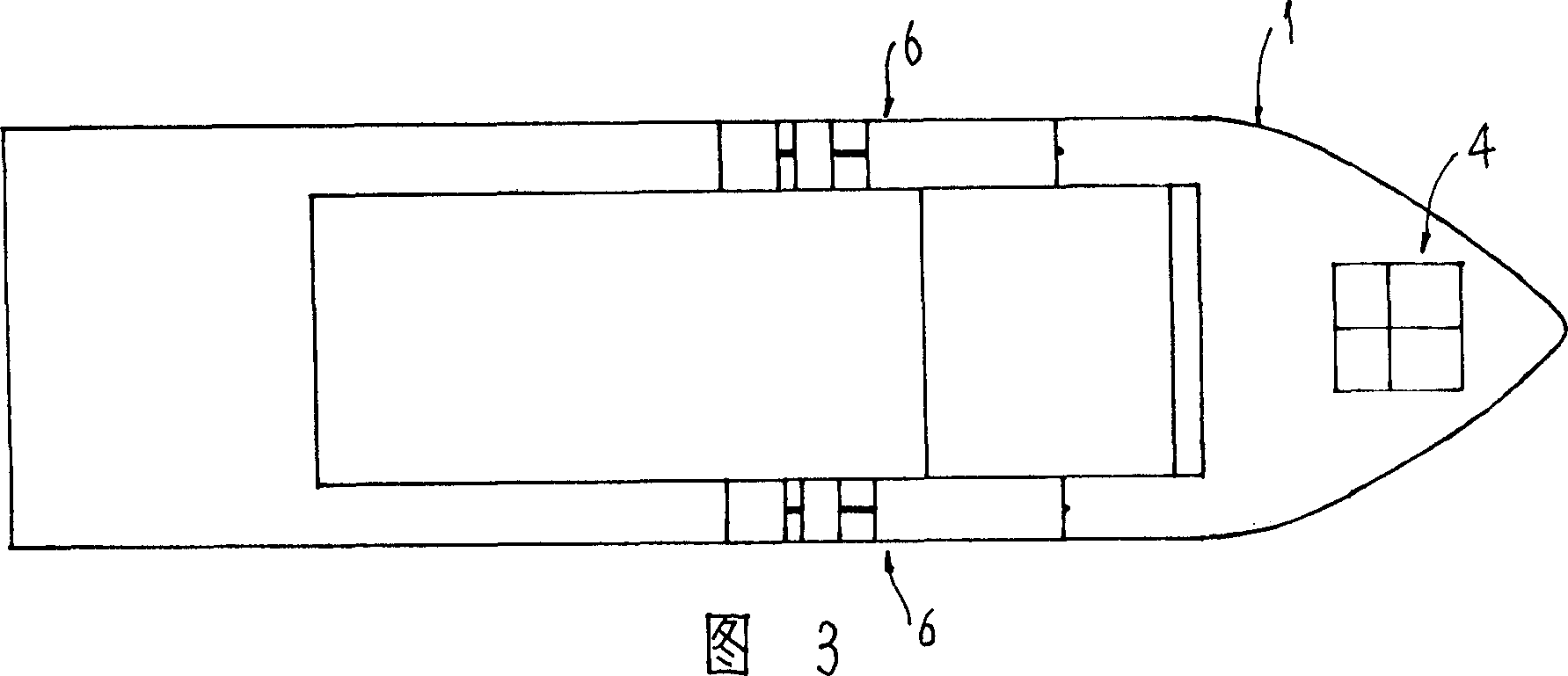

[0015] Referring to Figs. 1 to 3, a high-speed hovercraft hull of the present invention includes a hull 1 and a motor propulsion propeller 7 arranged at the stern of the hull 1, the bottom of the hull 1 is a flat bottom, and the midship of the hull 1 is a main body with an open bottom. The air chamber 2 is provided with a stable air chamber 3 with an open bottom on both sides of the main air chamber 2, and the partition plate between the stable air chamber 3 and the main air chamber 2 is wave-shaped to reduce the air flow in the air chamber and increase the hull height. 1; the hull 1 is provided with an air booster 4, and the air booster 4 is a turbo air booster, which is arranged at the bow of the hull 1; the high-pressure outlet of the air booster 4 is connected to the main air chamber 2 and the The stable air chamber 3 is connected; the bottom surface of the hull 1 at the rear of the main air chamber 2 is provided with a plurality of guide grooves 5 that are concave upward; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com