Voltage supply system for uninterrupted-power-supply detection of electronic product performance used in production line

An electronic product and electric detection technology, which is applied to the parts of electric measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of lower production efficiency, increase of production line length, waste of production line space, etc., and achieve compact station settings, reduce Distance, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

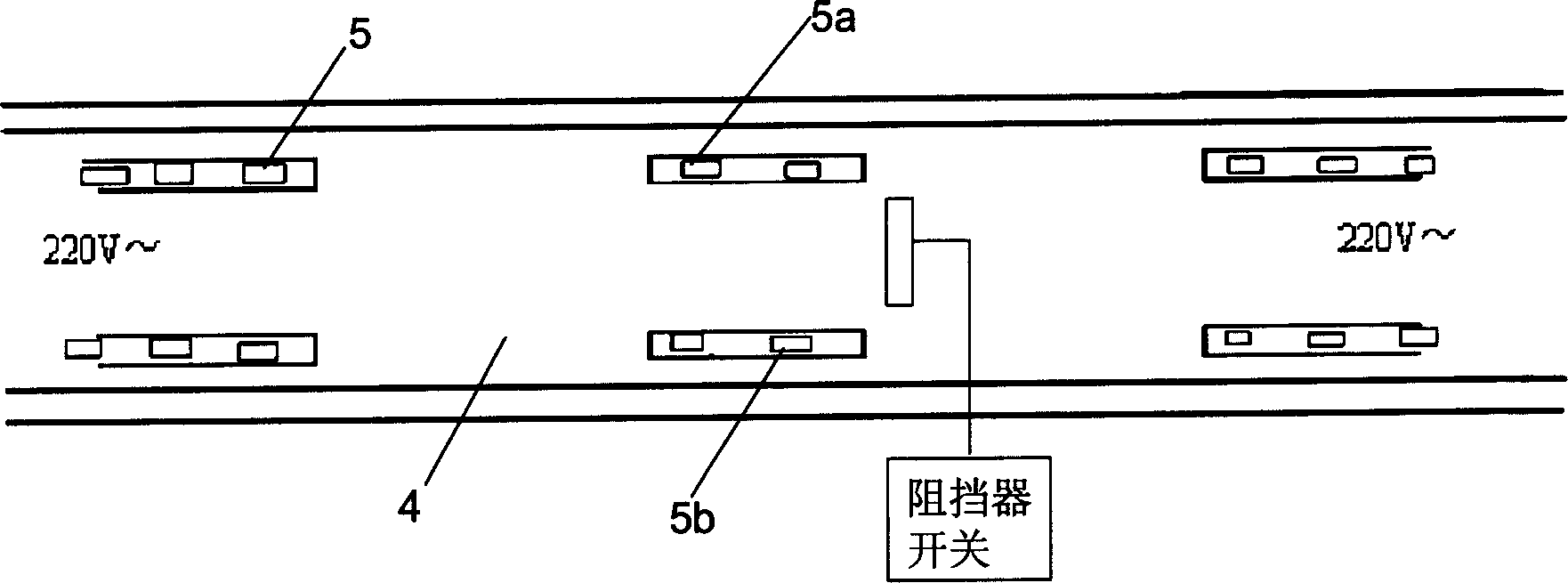

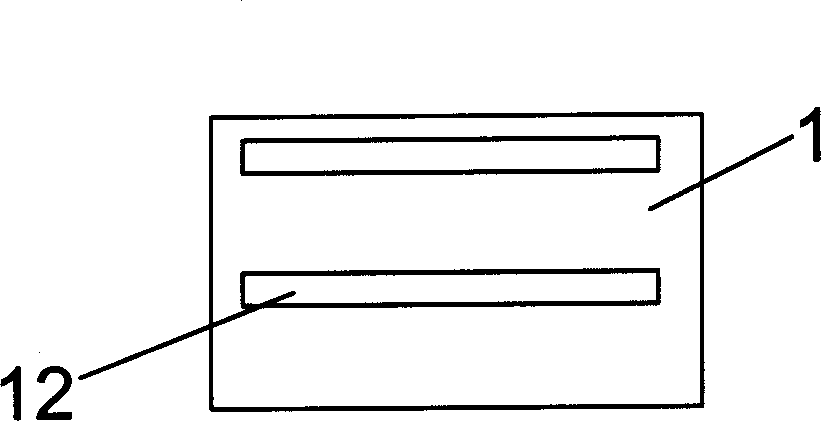

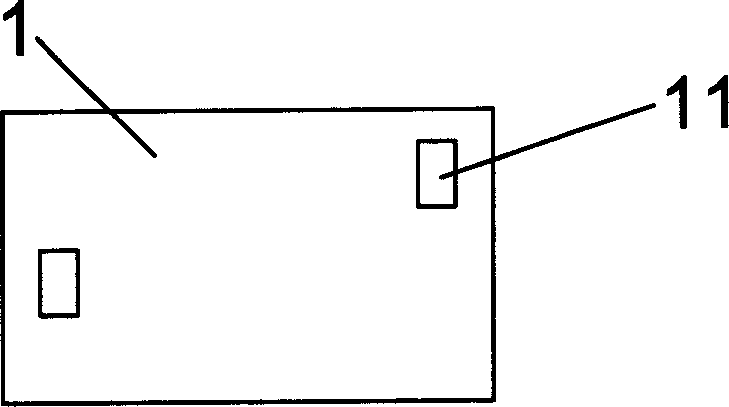

[0033] Embodiment 1: as Figure 4 As shown, a voltage supply system for continuously testing the performance of electronic products on the production line, including: a tooling board 1 for carrying electronic products, conductive devices 5a and 5b for testing stations, a voltage switching device 6, and a voltage switching control module 9. The detection voltage supply module 8 and the normal voltage supply module 2 . There is a conductive strip 12 on the back of the tooling board 1, which is used to make electrical contact with the conductive devices 5a and 5b of the detection station, and the detection voltage supply module 8 is connected to the voltage switching device 6, and is used to communicate with the voltage switching device 6 under the control of the voltage switching device 6. The conductive device of the detection station is selectively connected, the voltage switching device 6 is connected to the voltage switching control module 9, the normal voltage supply module...

Embodiment 2

[0046] As shown in FIG. 7 , the difference between this embodiment and Embodiment 1 lies in: a voltage switching device 6 and a voltage switching control module 9 . Such as Figure 6 As shown, the voltage switching device 6 of this embodiment includes a double-pole three-throw switch 63, and the two wires at the wire end of the double-pole three-throw switch 63 are respectively electrically connected to the conductive devices 5a and 5b of the detection station. The double-pole three-throw switch 63 can be contacted with contacts R, S, contacts P, Q, contacts X, Y respectively, and there is a normal voltage between the contacts R and S to provide the normal working voltage output by the module 2. There is a first detection voltage (low voltage lower than the normal operating voltage of electronic products) outputted by the detection voltage supply module 8 between points P and Q, and a second detection voltage (low voltage lower than the normal operating voltage of electronic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com