Water-supply cable for point welding machine

A water-passing cable and spot welding machine technology, applied in the direction of power cables, cables, circuits, etc., can solve the problems of easy friction between two poles, heating, tightness of twisting, heating of cable conductors, etc., and achieve a broad market and promotion and application prospects , good product quality, soft cable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

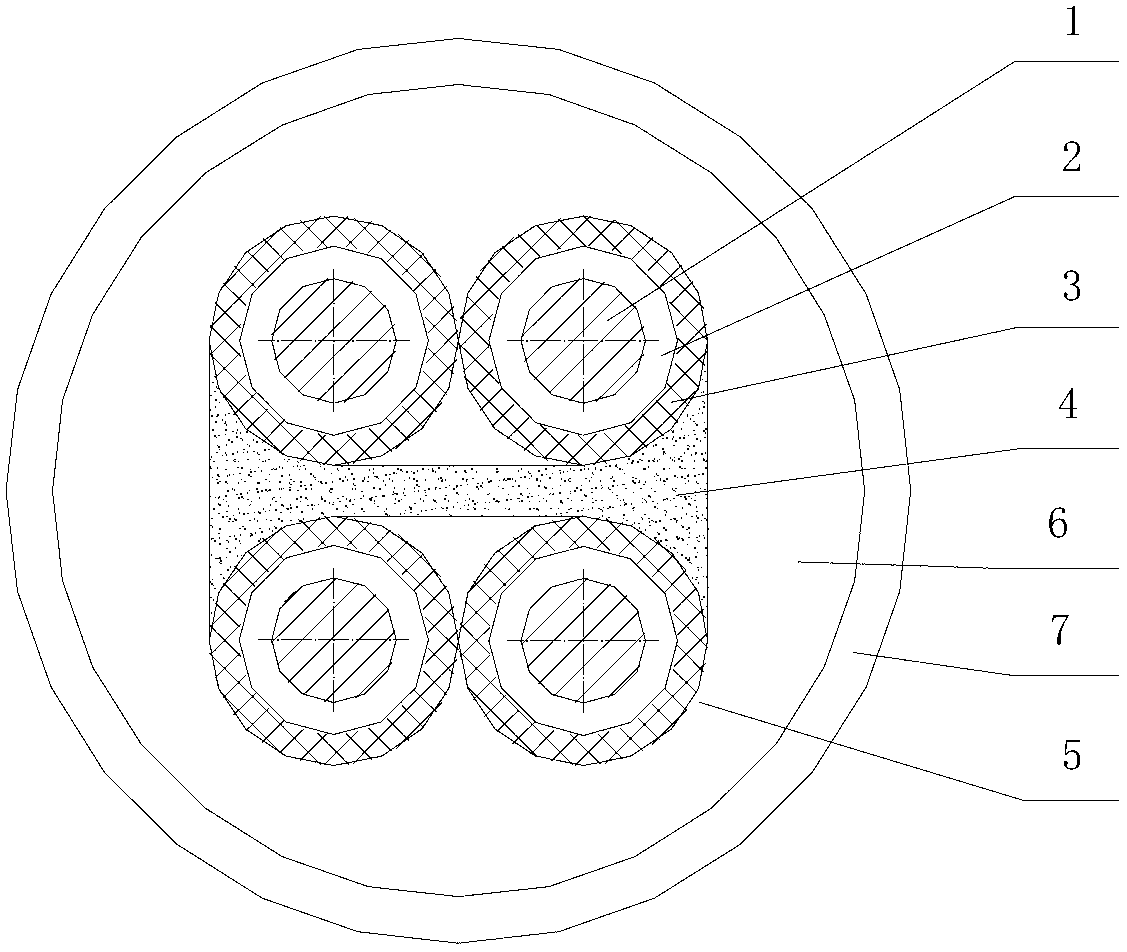

[0030] In conjunction with accompanying drawing, a kind of water-through cable for spot welding machine, it comprises by paired cabled conductor 1 through insulating layer 4 and forms conductive wire core 5, and conductor 1 outer wrapping heat-resistant insulating layer 2 of polytetrafluoroethylene material, The outer wrapping material of the heat-resistant insulation layer 2 is fine nylon wire with a temperature resistance grade of 200°C, and is woven into a nylon wire mesh 3 with a weaving density of not less than 95%. The conductor 1 is 7-14 thin copper wires. Conductor 1 twisting system adopts strand bundle twisting pitch ratio less than 12, multiple twisting pitch ratio is less than 10, four groups of two grades, every two groups of one grade, each group is cabled separately, and the heat resistance between poles and poles is 180°C The insulating rubber pad is used as the isolation layer 4 to form the conductive wire core 5. The material outside the wire core 5 is XH-31A r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature class | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com