Water drainage pump

A drainage pump and impeller technology, applied to pumps, pump devices, pump components, etc., can solve problems such as insufficient starting force, impact noise, customer dissatisfaction, cracks in the impeller 50 of the rotating shaft head, etc., to minimize damage and minimize noise the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

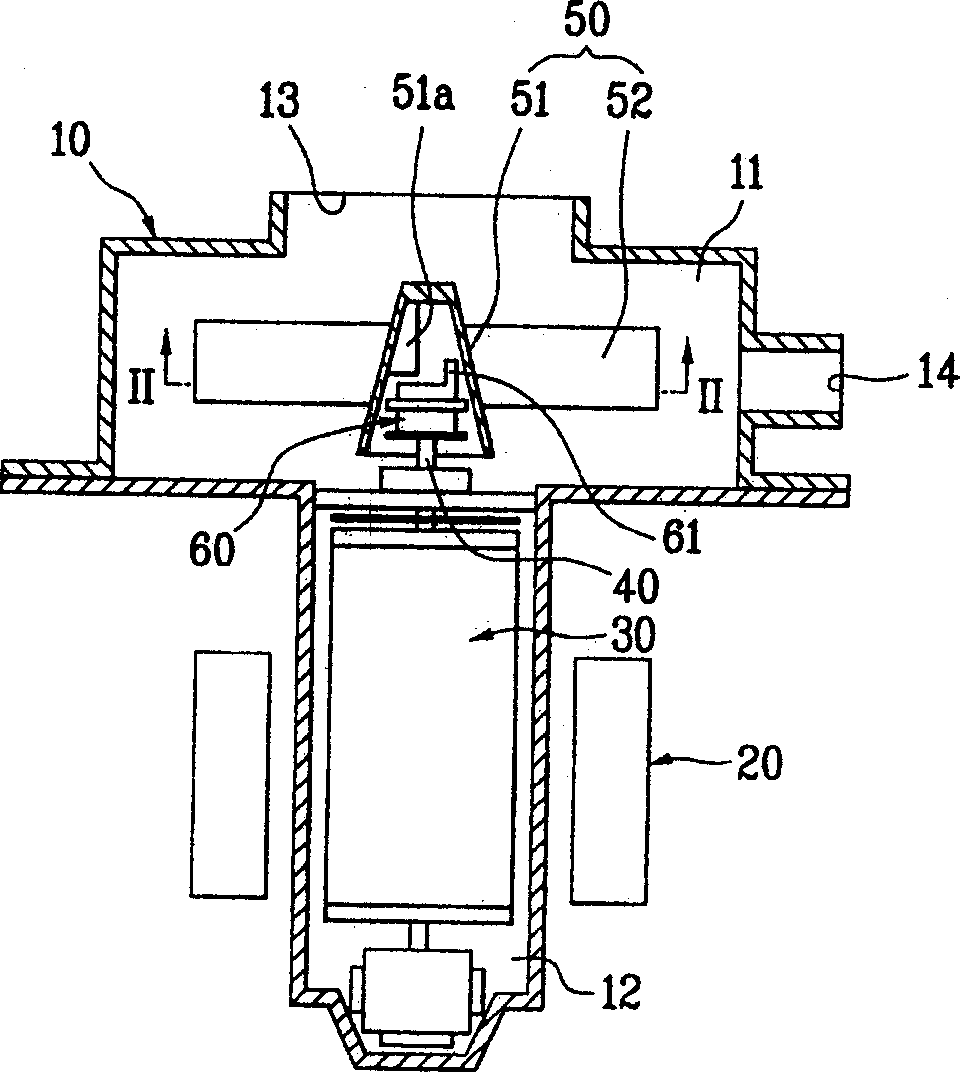

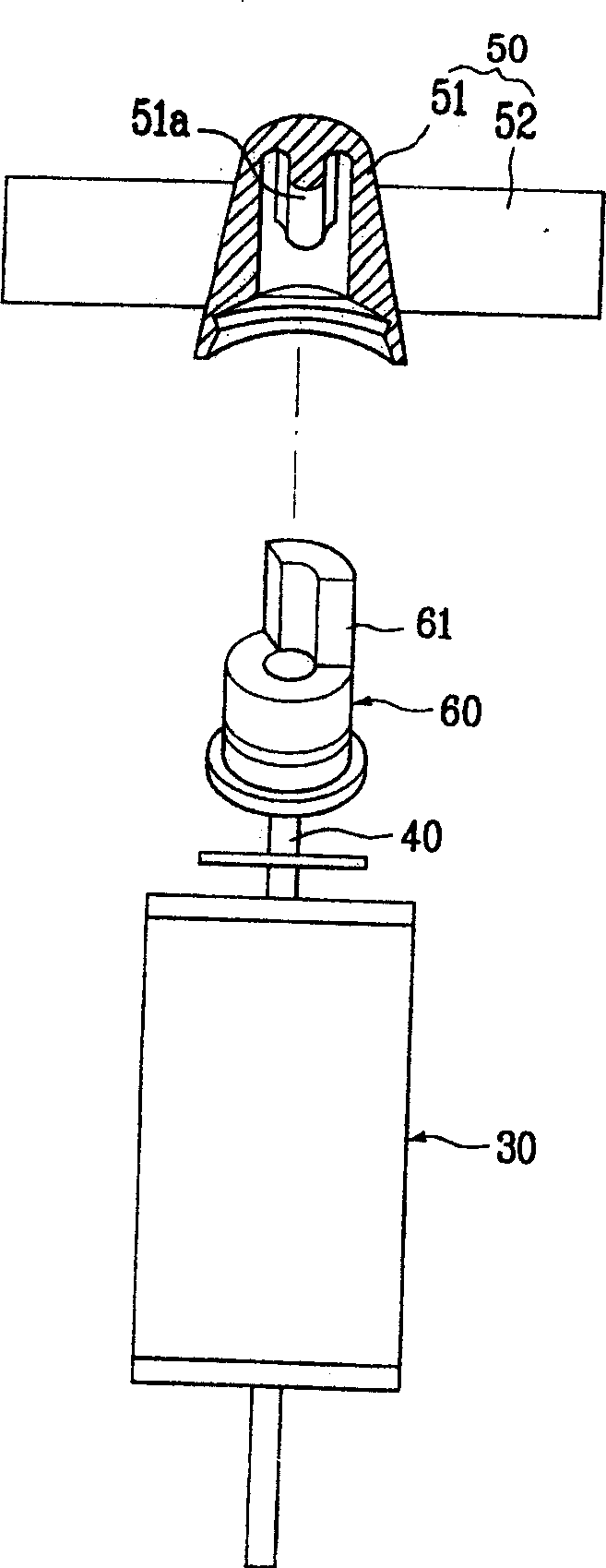

[0049] Below, will refer to Figure 5 to Figure 9 , the possible embodiments of the drainage pump according to the present invention will be described in more detail.

[0050] first, Figure 5 and Image 6 A drain pump according to an embodiment of the present invention is shown.

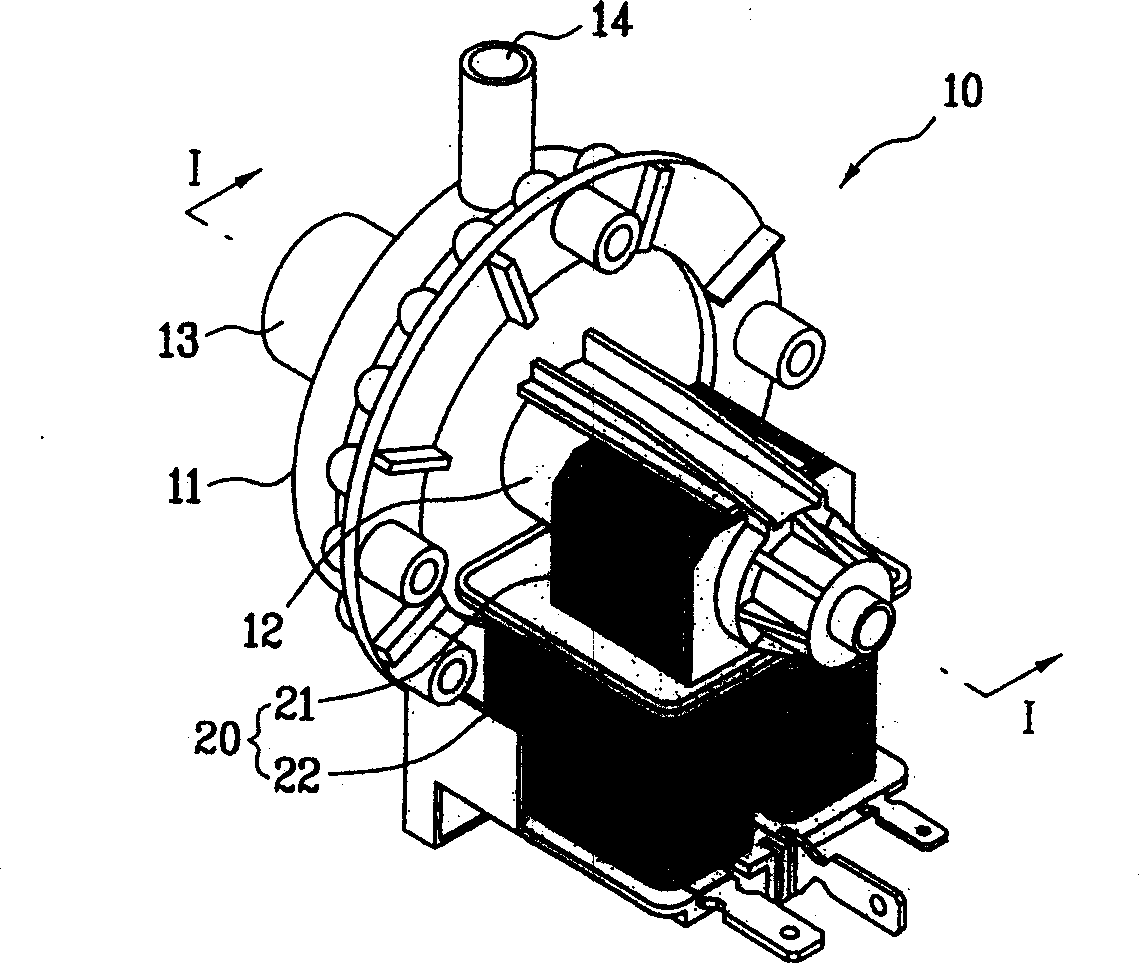

[0051] That is, the drainage pump according to the embodiment of the present invention generally includes the following components: the casing 100; the impeller 500; the rotating shaft 400; and the driving force transmission device.

[0052] Here, the casing 100 includes an impeller accommodating portion 110 for accommodating the impeller 500 and a rotor accommodating portion 120 for accommodating the rotor 300, and the casing constitutes the appearance of the drain pump.

[0053] At this time, the rotor accommodating portion 120 includes a rotor 300 made of permanent magnets. The stator 200 is provided on the outer periphery of the rotor housing portion 120 .

[0054] In addition, a suction port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com