Non-leakaging notch full-sealing piston ring

A fully sealed and leak-free technology, applied to piston rings, engine components, machines/engines, etc., to achieve good sealing performance, reduce replacement frequency, and reduce exhaust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Common type cutout no leakage fully sealed piston damage

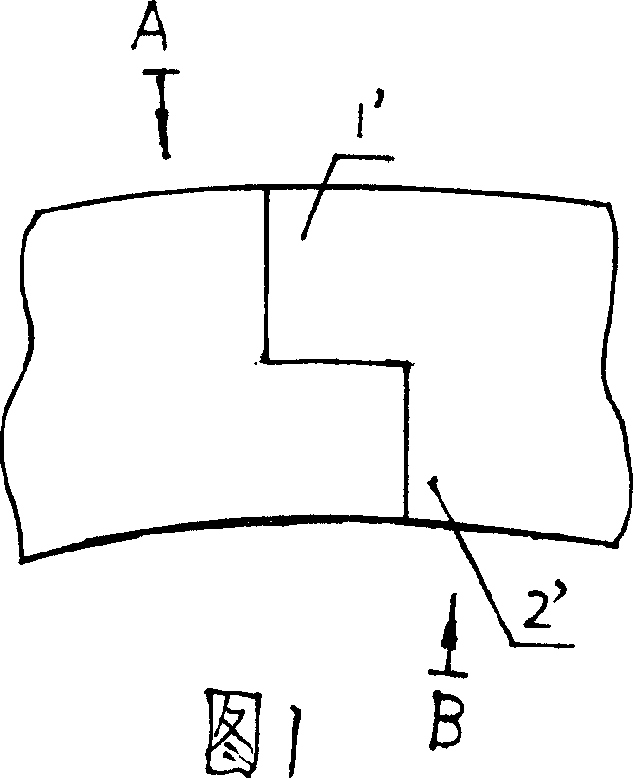

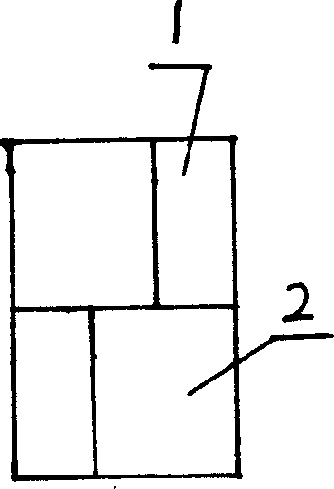

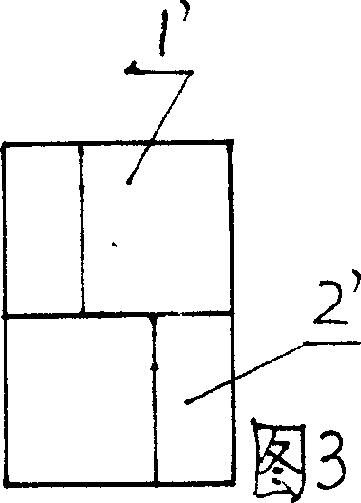

[0019] As shown in Figures 1 to 5, there is a cutout on the sealing ring, and the cross section of the ring is rectangular. The difference is that each cut end has an outer convex kiss and an inner convex kiss with a rectangular cross section and different protruding lengths. The inner surfaces of the inner and outer convex kisses on each incision end are engaged with the corresponding inner surfaces of the inner and outer convex kisses on the opposite incision end. The so-called engagement means that the inner surfaces are closely matched with each other without gaps, and the end surfaces of all the convex kisses are opposite to each other. There is an open gap between the notched end faces. In this embodiment, the axial width of the outer convex kiss 1 on the cutout at one end is smaller than the axial width of the inner convex kiss, and the axial width of the corresponding outer convex kiss 1' on th...

Embodiment 2

[0020] Embodiment 2 Simplified cut-out leak-free fully-sealed piston ring

[0021] This example is basically the same as the first example, except that the radial width of the outer convex kiss 3 is greater than the radial width of the inner convex kiss 4 .

[0022] Although the present embodiment has an upper and lower through slit on the inner side, the slit is always located in the piston ring groove during use. Regardless of whether the piston moves up or down, the lower or upper wall of the ring groove will seal the cutout, so no gas or oil leakage will occur, and the entire piston ring still plays a fully sealed role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com