Sanitation device for train carriage toilet

A sewage device and carriage technology, applied in transportation and packaging, railway car body parts, sanitary equipment, etc., can solve the problems of troublesome opening or closing of the sewage storage tank, and the inability of the train crew to actually control, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

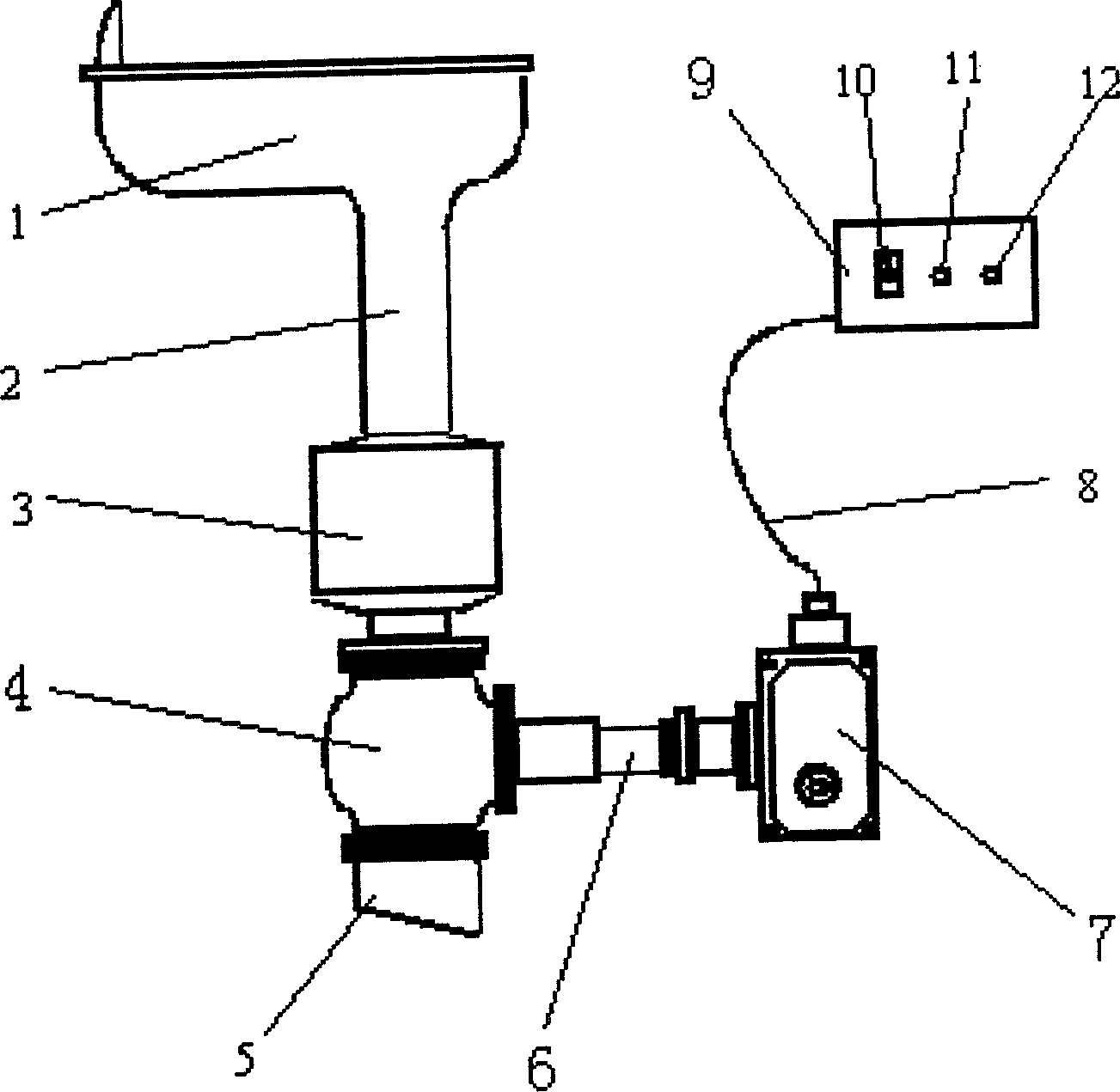

Embodiment 1

[0018] refer to figure 1 , a kind of blowdown device in the train compartment toilet, the toilet 1 communicates with the channel 2, and the channel 2 communicates with the dirt storage tank 3, and a valve is installed at the outlet of the dirt storage tank 3, and the valve is installed in the valve shell 4, and the valve A section of dirt discharge pipe 5 can be connected to the bottom of the shell 4, and the valve shell 4, the dirt storage tank 3 and the dirt discharge pipe 5 are connected by flanges. The valve is fixedly connected to the output shaft of the electric adjustment actuator 7 through the transmission rod 6. The electric adjustment actuator 7 is equipped with a motor and a limit switch. The controller 9 is equipped with a DC power supply, and the DC power supply has a positive and negative voltage switching switch 10 , a positive voltage value adjustment button 11 , and a negative voltage value adjustment button 12 . The valve, the electric adjustment actuator an...

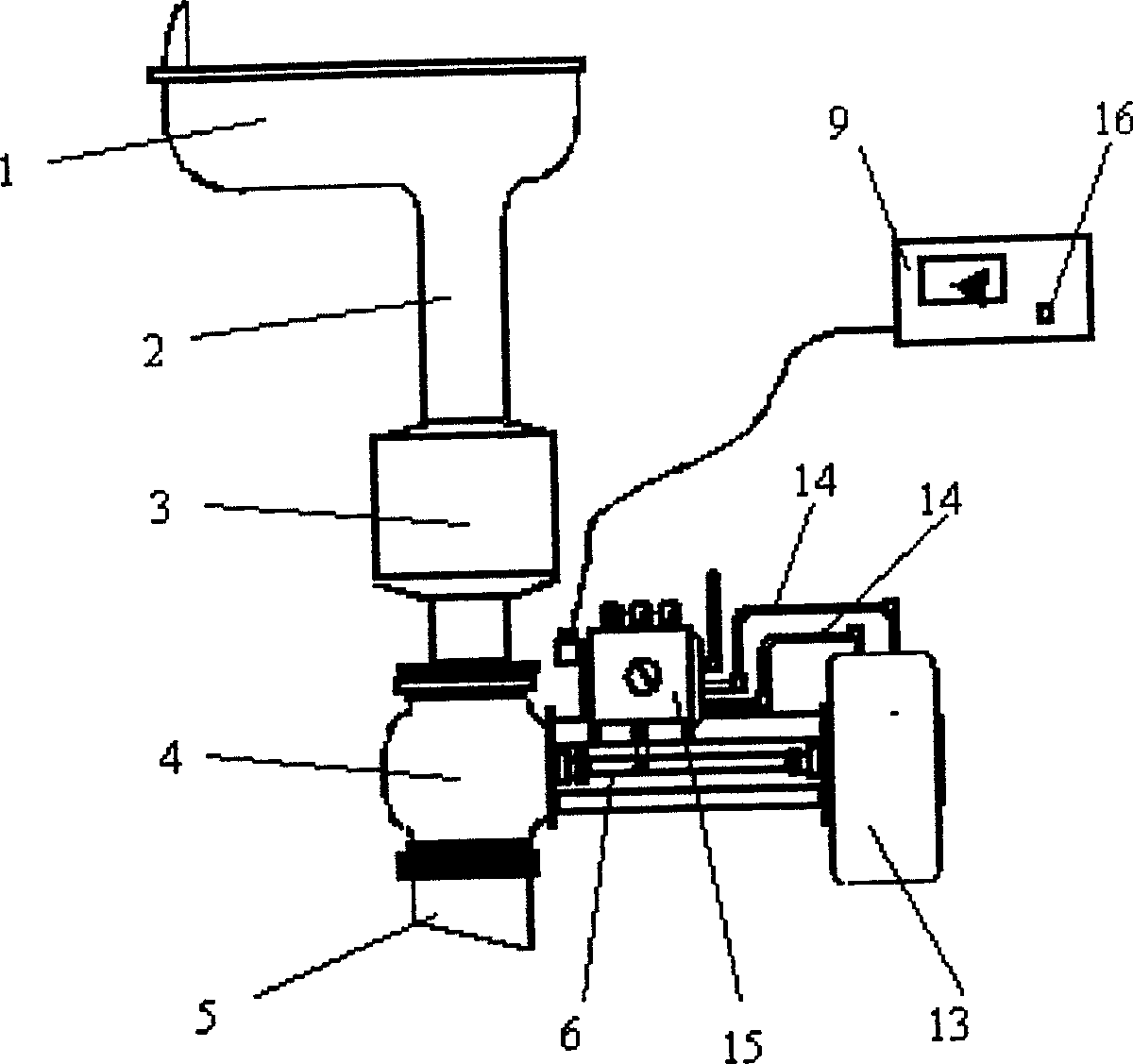

Embodiment 2

[0021] refer to figure 2 , a kind of blowdown device in the train compartment toilet, the toilet 1 communicates with the channel 2, and the channel 2 communicates with the dirt storage tank 3, and a valve is installed at the outlet of the dirt storage tank 3, and the valve is installed in the valve shell 4, and the valve A section of dirt discharge pipe 5 can be connected to the bottom of the shell 4, and the dirt storage tank 3 of the valve shell 4 and the dirt discharge pipe 5 are connected by flanges. The valve is fixedly connected to the output shaft of the pneumatic actuator 13 through the transmission rod 6, the pneumatic actuator 13 communicates with the electro-pneumatic positioner 15 through the gas pipe 14, and the electro-pneumatic positioner 15 is electrically connected with the output end of the controller 9. The controller 9 has a power supply and an output current adjustment button 16 . The valve, pneumatic regulating actuator, electro-pneumatic positioner and...

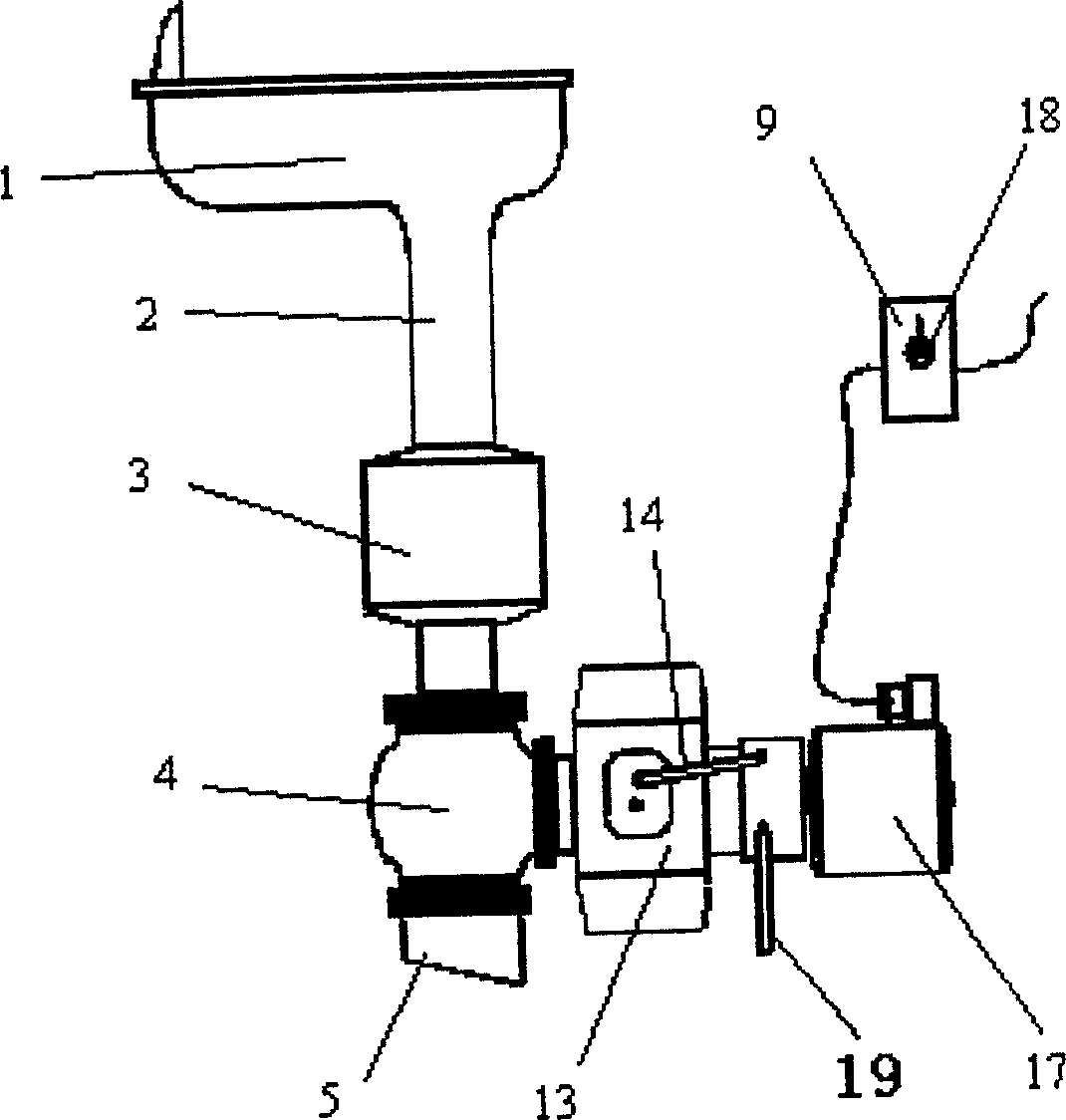

Embodiment 3

[0025] refer to image 3 , a kind of blowdown device in the train compartment toilet, the toilet 1 communicates with the channel 2, and the channel 2 communicates with the dirt storage tank 3, and a valve is installed at the outlet of the dirt storage tank 3, and the valve is installed in the valve shell 4, and the valve A section of dirt discharge pipe 5 can be connected to the bottom of the shell 4, and the dirt storage tank 3 of the valve shell 4 and the dirt discharge pipe 5 are connected by flanges. The valve is fixedly connected with the output shaft of the pneumatic actuator 13, the pneumatic actuator 13 communicates with the electromagnetic valve 17 connected with the air source through the air pipe 14, and the air pipe 19 is connected with the air source. The wiring terminal of the electromagnetic valve 17 connected with the air source is electrically connected with the controller 9, and the controller 9 is equipped with a power switch 18. Valves, pneumatic actuators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com