Online analysis sample gas air-cooled dedusting and dehumidification device and application method

A sample gas air-cooled and sample gas technology, applied in the field of decompression refrigeration, can solve problems such as inconvenient operation, damage to analytical instruments, and immeasurable losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

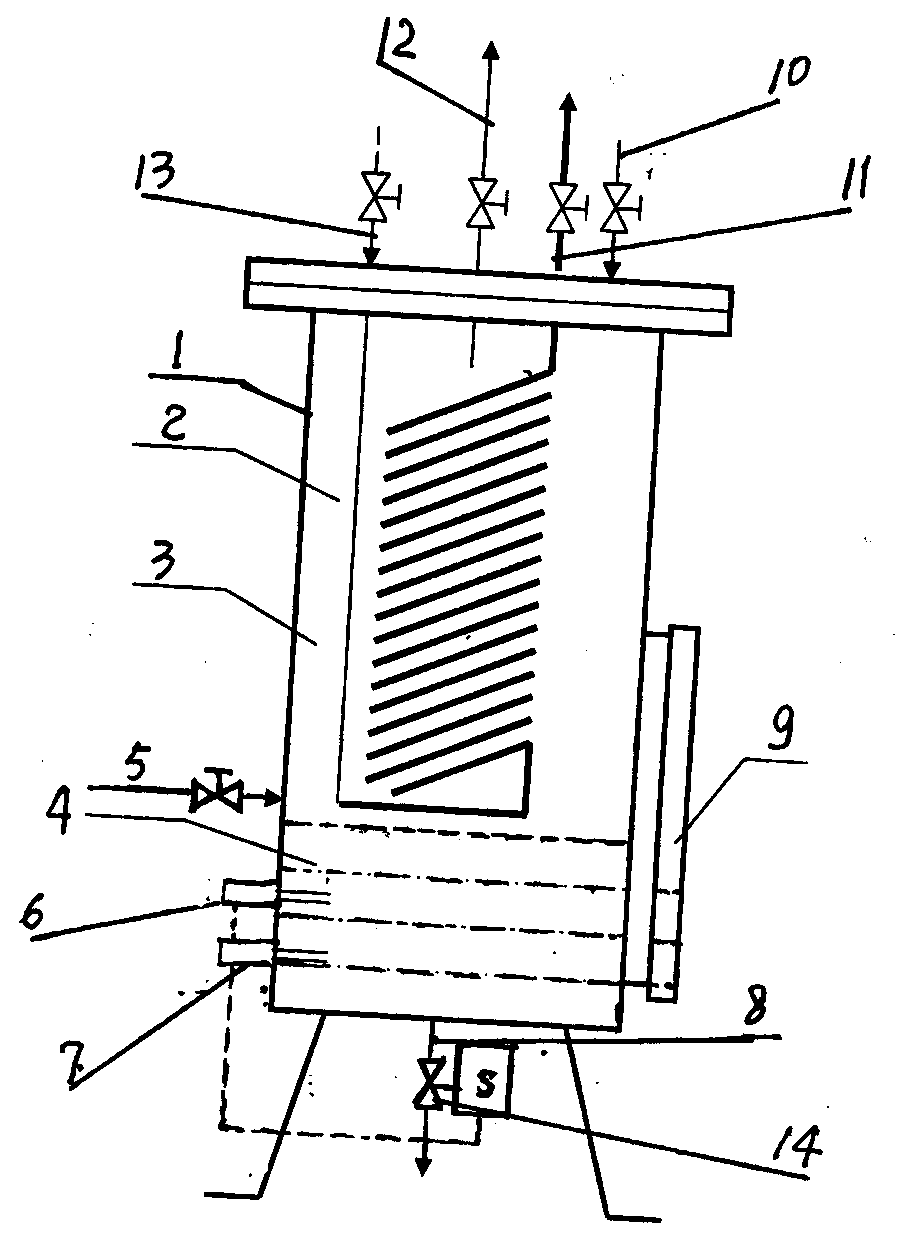

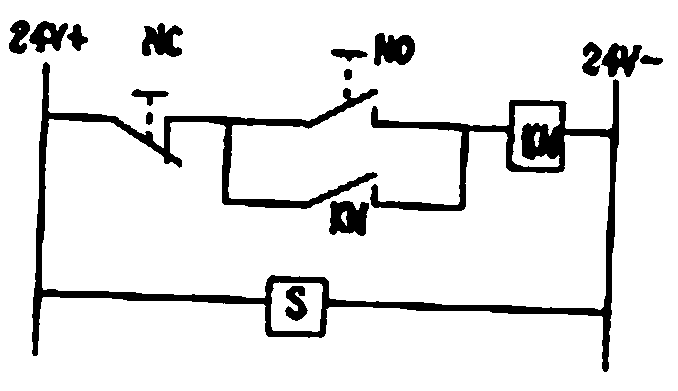

[0014] Embodiment 1. The present invention includes a housing 1, an air-cooled cooling condensate chamber 2, an air chamber partition 3, an ash storage liquid storage chamber 4, a sample gas inlet conduit 5, a first tuning fork switch 6, a second tuning fork switch 7, Sewage discharge conduit 8, liquid level gauge 9, cleaning water inlet conduit 10, instrument air outlet conduit 11, sample gas outlet conduit 12, instrument air intake conduit 13, electromagnetic automatic sewage valve 14, the upper end of the housing 1 is welded Along with the matching flange and the blind flange, an air-cooled cooling condensate chamber 2 is arranged in the middle of the housing 1;

Embodiment 2

[0015] Embodiment 2. The air chamber partition 3 is located in the middle of the housing 1 and the air-cooled cooling condensate chamber 2. The middle of the air chamber partition 3 and the housing 1 is an air chamber, and the air chamber is filled with stainless steel wire cleaning balls.

Embodiment 3

[0016] Embodiment 3. The sample gas inlet conduit 5 is installed on the sample gas inlet at a distance of 300 mm from the bottom of the housing 1 , and a valve is installed on the sample gas inlet conduit 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com